PBT fiber manufacturing method based on high speed one-step method

A manufacturing method and step technology, which is applied in the field of PBT filament fiber manufacturing, can solve the problems of different PBT fibers, feeling hard and uncomfortable, and the fabric feels bad to the body, so as to achieve lower production costs, product quality stability and better quality. The effect of dyeing performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: Take the PBT fiber of 80dtex / 24f as an example with high-speed one-step method production, and manufacturing method is as follows:

[0026] (1) drying: drying the PBT slices, and ending the drying when the moisture content is lower than 40ppm;

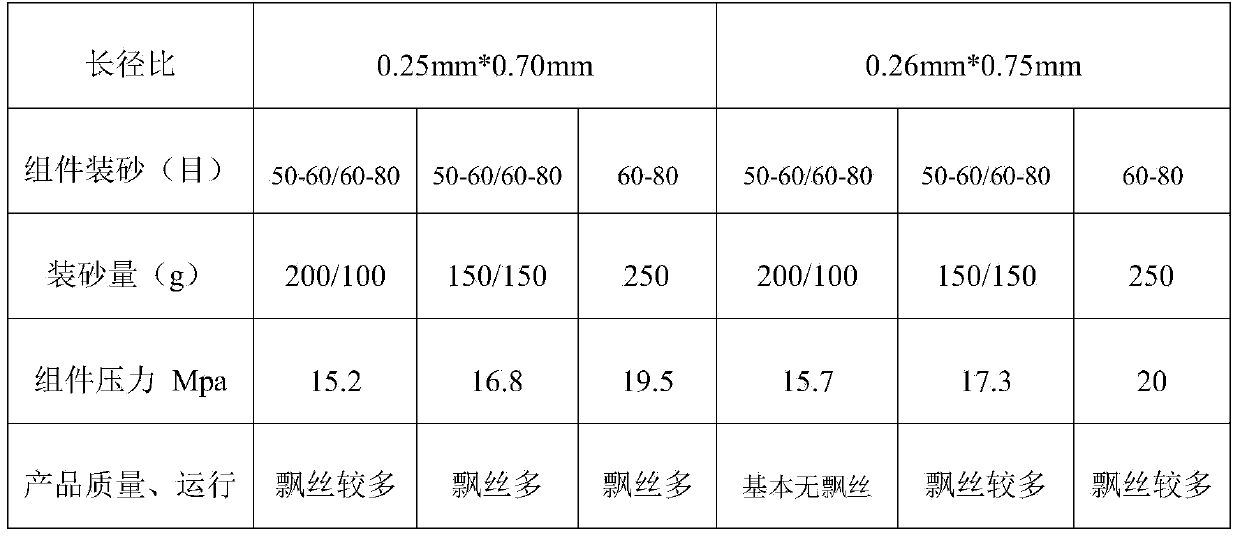

[0027] (2) Component preparation: select a spinneret with an aperture of 0.26*0.75;

[0028] (3) Melt extrusion: PBT chips are heated and melted at a temperature of 260°C in a screw extruder, and the heated and melted polymer melt enters an online switchable melt filter after being extruded by a screw;

[0029] (4) Filtration: filter with an online switchable melt filter to ensure the continuity of spinning and the constant pressure of the melt;

[0030] (5) Side-blowing cooling: After the filaments are extruded through the spinneret, the air-conditioning air with a uniform temperature of 17°C and a wind speed of 0.6m / min is used for side-blowing cooling. A special side-blowing homogenization device is used to Co...

Embodiment 2

[0036] Embodiment 2: roughly the same step as in Example 1, the difference is that the micropore diameter of the step (2) spinneret is 0.25mm, the aperture 0.60mm, the melting temperature of the step (3) is 255 ℃, and the step (5) Adopt the air-conditioning wind of wind temperature 16 ℃, wind speed 0.4m / min to carry out uniform side blowing, the spinning speed of step (6) is 3800m / min.

Embodiment 3

[0037] Embodiment 3: roughly the same step as in Example 1, the difference is that the micropore diameter of the step (2) spinneret is 0.30mm, the aperture 0.80mm, the melting temperature of the step (3) is 265 ℃, and the step (5) Adopt the air-conditioning wind of wind temperature 18 ℃, wind speed 0.8m / min to carry out uniform side blowing, the spinning speed of step (6) is 4200m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com