Surface air cooler with wet films of composite structures

A composite structure, surface cooler technology, applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of capillary structure removal, rapid freezing, complex structure, etc., to achieve the effect of easy cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

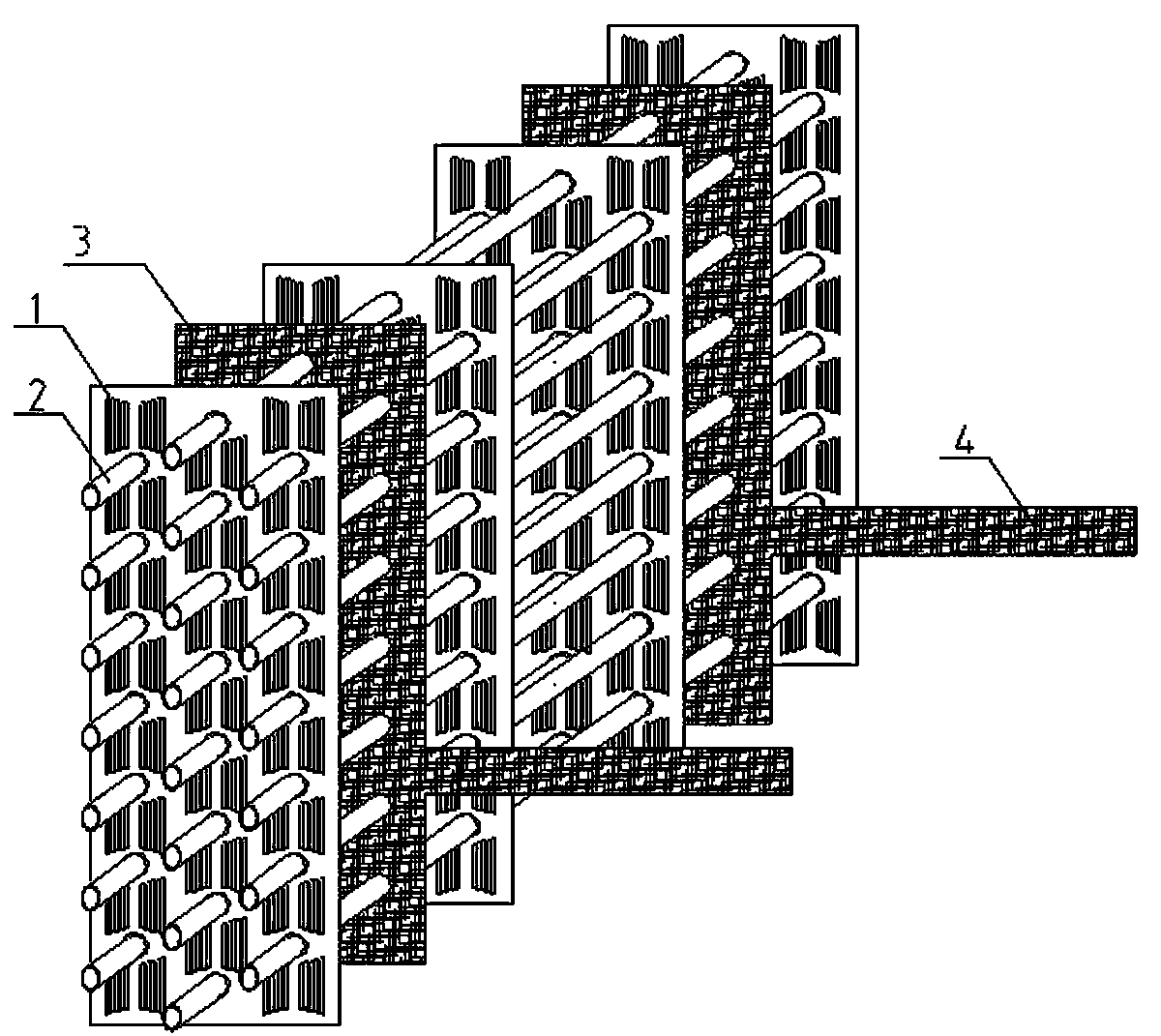

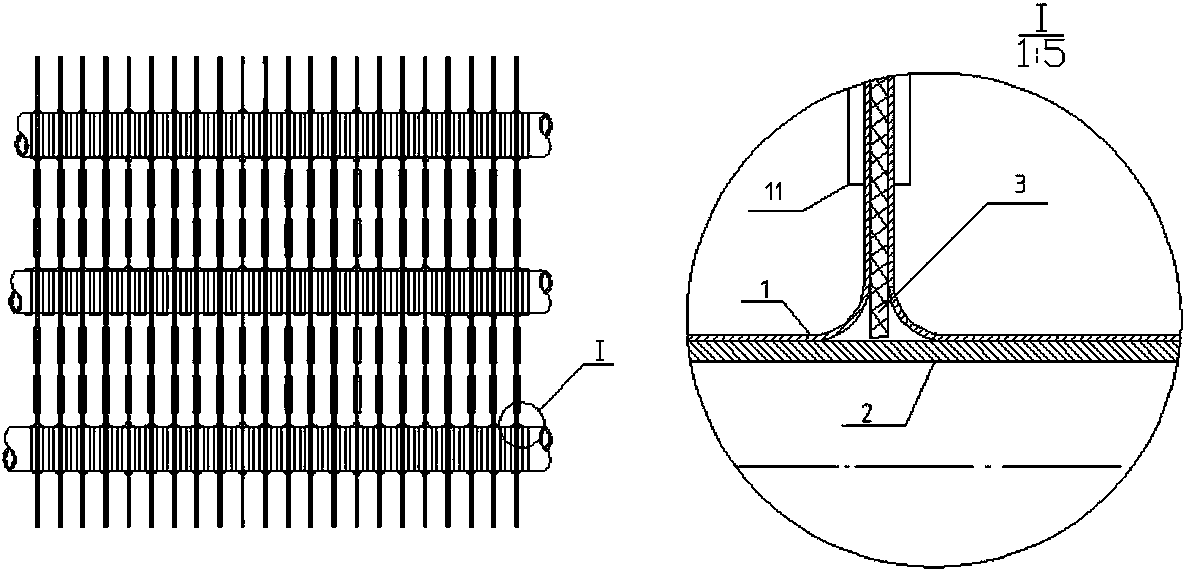

[0059] refer to figure 1 ,and figure 2 , the composite structure wet film surface cooler provided in this embodiment includes a plurality of fins 1 arranged in parallel at intervals and a plurality of heat exchange tubes 2 passing through the fins 1, and the heat exchange tubes 2 contain flowing refrigerant; A wet film layer 3 is pressed between the two fins 1 to form a "sandwich" structural unit; the dimensions of the wet film layer 3 are basically the same as those of the fins 1, so that the fins 1 are completely covered by the wet film layer 3 and in close contact , to ensure that water naturally, evenly and rapidly infiltrates to the entire surface of each fin 1 without any power.

[0060] refer to Figure 4 and Figure 5 , the water supply mode of the wet film layer 3 adopts the scheme of water-absorbing belt 4 plus water storage tank 5, and a water-absorbing belt 4 for introducing water into the wet film layer 3 extends outward from the middle and lower side of the ...

Embodiment 2

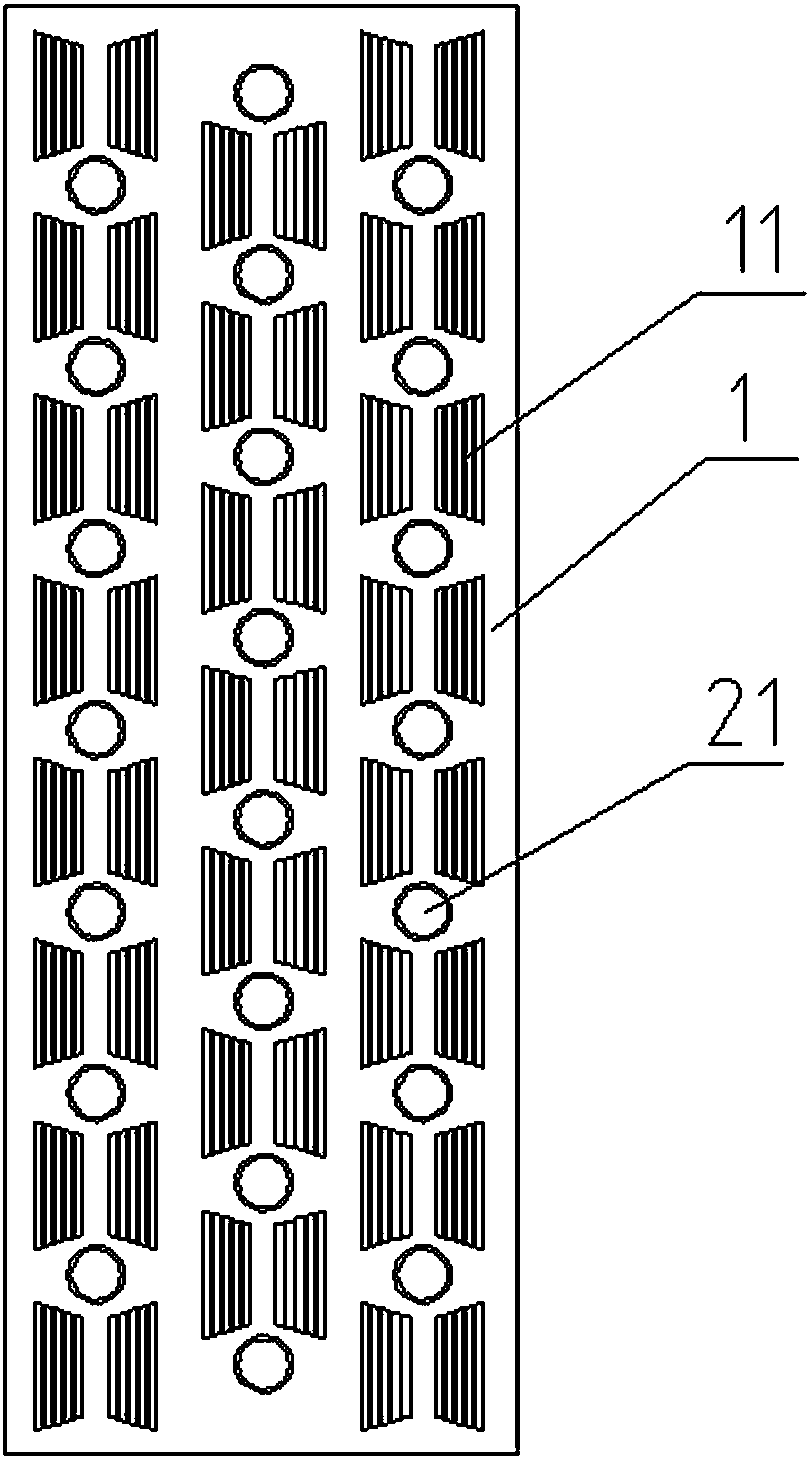

[0077] The difference from Example 1 is that the wet film layer 3 is uniformly distributed on one side of each fin 1 in strip shape, and the wet film layers 3 of all fins 1 can be arranged on the same side or on different sides.

Embodiment 3

[0079] The difference from Example 1 is that in some of the fins 1, a wet film layer 3 is pressed between two adjacent fins 1 to form a "sandwich" structure; in the other part of the fins 1, one part of each fin 1 The side is pressed with a wet film layer 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com