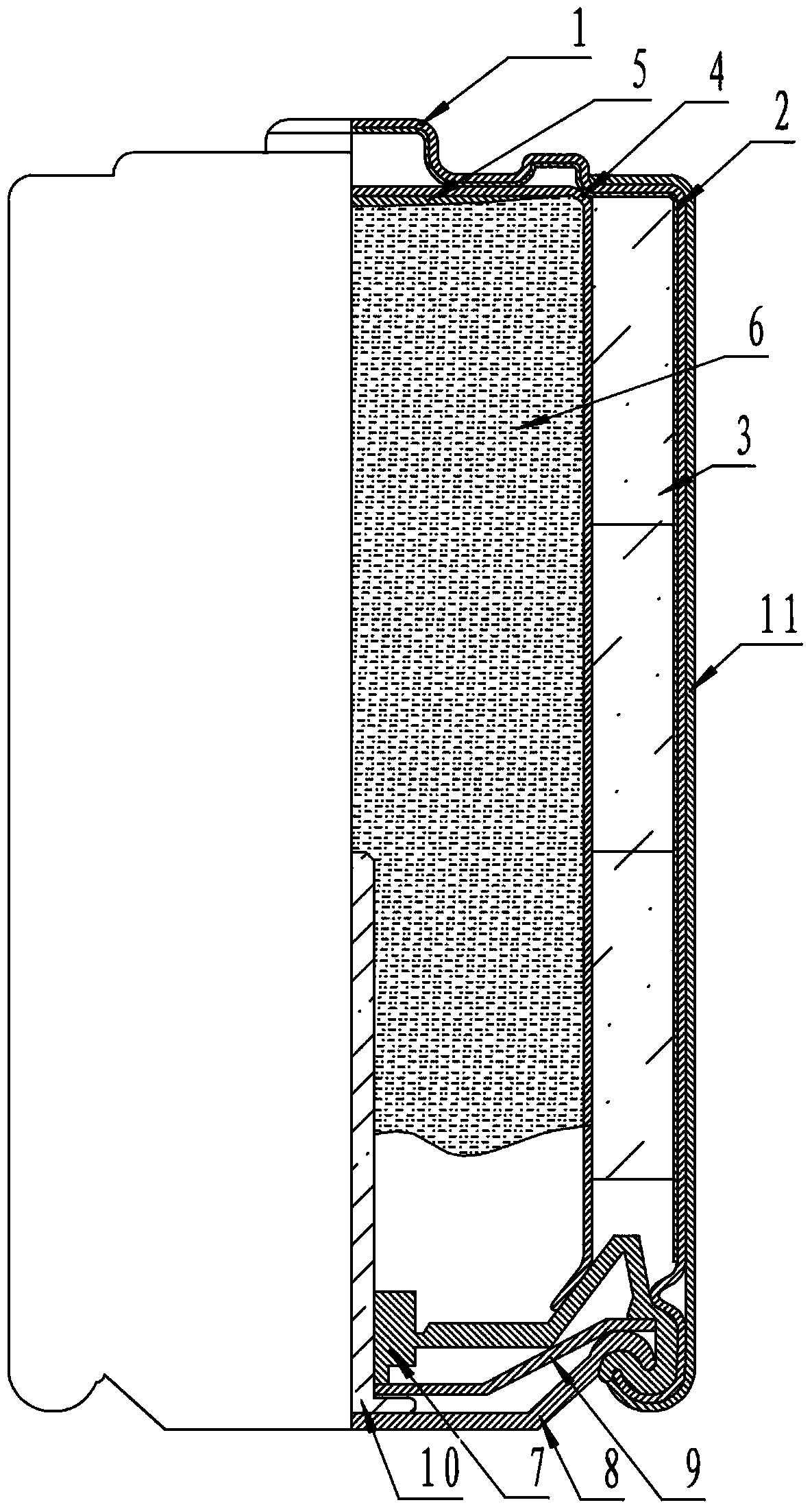

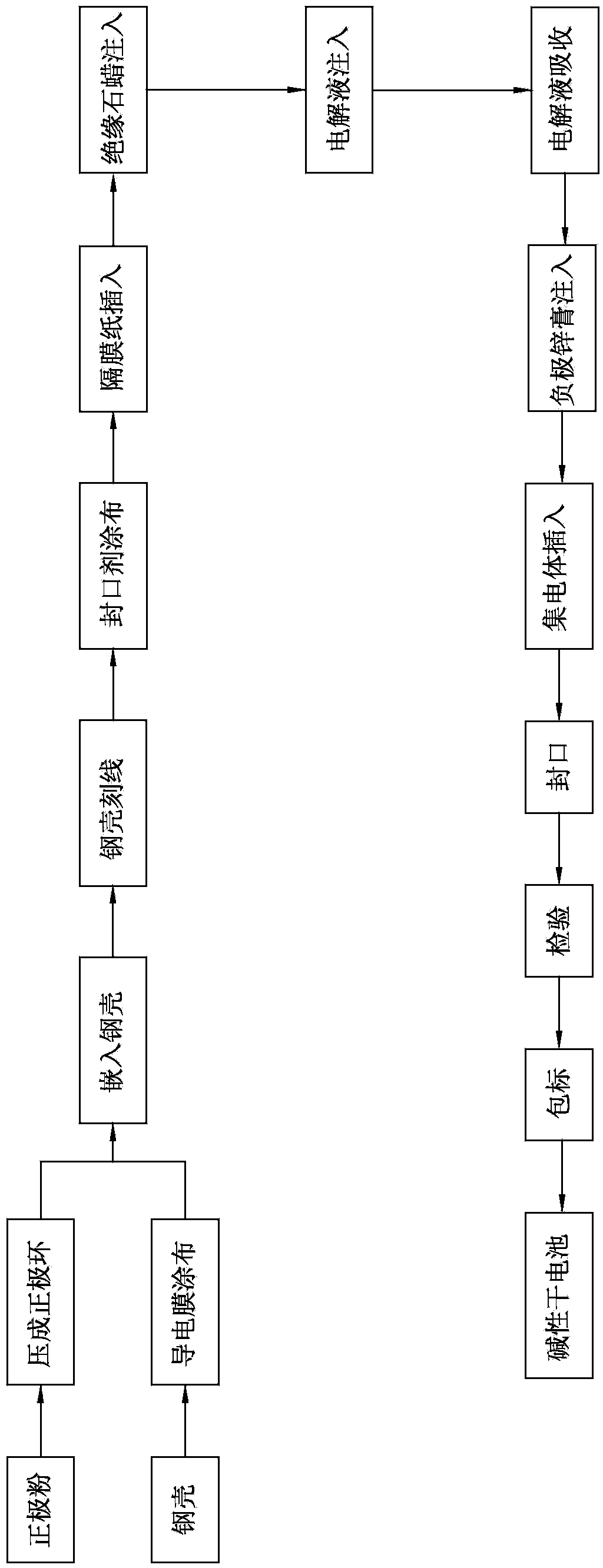

Alkaline dry battery and preparation method thereof

A dry battery and alkaline technology, applied in the field of alkaline dry batteries and their preparation, batteries and their preparation, can solve the problems of adding heavy electrolyte, destroying electronic parts, corroding metals, etc., to enhance discharge and battery life, and reduce consumption , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

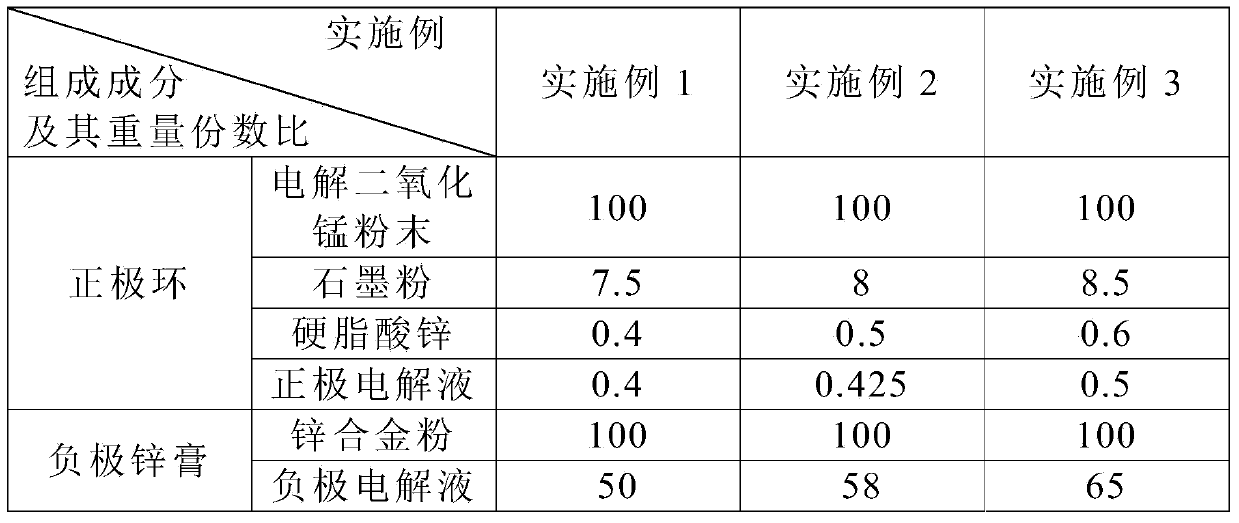

Embodiment 1

[0037]Weigh the raw materials according to the composition and weight percentage ratio of the positive electrode ring of Example 1 alkaline dry battery in Table 1, the composition and weight percentage of the electrolytic manganese dioxide powder in the raw material are: manganese dioxide: ≥ 92%, water : ≤3%, sulfate radical: <1.5%, hydrochloric acid insoluble matter: <0.06%; the particle size distribution range of electrolytic manganese dioxide powder is 10 μm to 150 μm, and the ratio of electrolytic manganese dioxide powder with particle size below 75 μm is greater than 90% %, the ratio of electrolytic manganese dioxide powder with a particle size above 125 μm is less than 2%; the positive electrode electrolyte is potassium hydroxide aqueous solution, and the weight percentage of potassium hydroxide is 39%. Then fully mix the electrolytic manganese dioxide powder and graphite powder, add the positive electrode electrolyte and stir evenly after mixing, then perform tableting, ...

Embodiment 2

[0041] Weigh the raw materials according to the composition and weight percentage ratio of the positive electrode mixture pellets of Example 2 alkaline dry battery in Table 1, the composition and weight percentage of the electrolytic manganese dioxide powder in the raw materials are: manganese dioxide: ≥ 95% , water: ≤1%, sulfate radical: <1.0%, hydrochloric acid insoluble matter: <0.06%; the particle size distribution range of electrolytic manganese dioxide powder is 10 μm to 150 μm, and the ratio of electrolytic manganese dioxide powder with particle size below 75 μm More than 95%, the ratio of electrolytic manganese dioxide powder with a particle size of 125 μm or more is less than 1%; the positive electrode electrolyte is potassium hydroxide aqueous solution, and the weight percentage of potassium hydroxide is 39%. Then fully mix the electrolytic manganese dioxide powder and graphite powder, add the positive electrode electrolyte and stir evenly after mixing, then perform t...

Embodiment 3

[0045] Weigh the raw materials according to the composition and weight ratio of the positive electrode mixture pellets of Example 3 alkaline dry battery in Table 1, and the composition and weight percentage of the electrolytic manganese dioxide powder in the raw materials are: manganese dioxide: ≥ 91% , water: ≤2%, sulfate group: <1.3%, hydrochloric acid insoluble matter: <0.06%; the particle size distribution range of electrolytic manganese dioxide powder is 10 μm to 150 μm, and the ratio of electrolytic manganese dioxide powder with a particle size below 75 μm More than 92%, the ratio of electrolytic manganese dioxide powder with a particle size of 125 μm or more is less than 1%; the positive electrode electrolyte is potassium hydroxide aqueous solution, and the weight percentage of potassium hydroxide is 39%. Then fully mix the electrolytic manganese dioxide powder and graphite powder, add the positive electrode electrolyte and stir evenly after mixing, then perform tabletin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com