Few-layer MoS2 uniform modified multi-stage structure TiO2 photocatalyst and preparation method thereof

A photocatalyst and uniform technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low photocatalytic activity, low photogenerated electron transmission rate, etc., and achieve the effect of high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

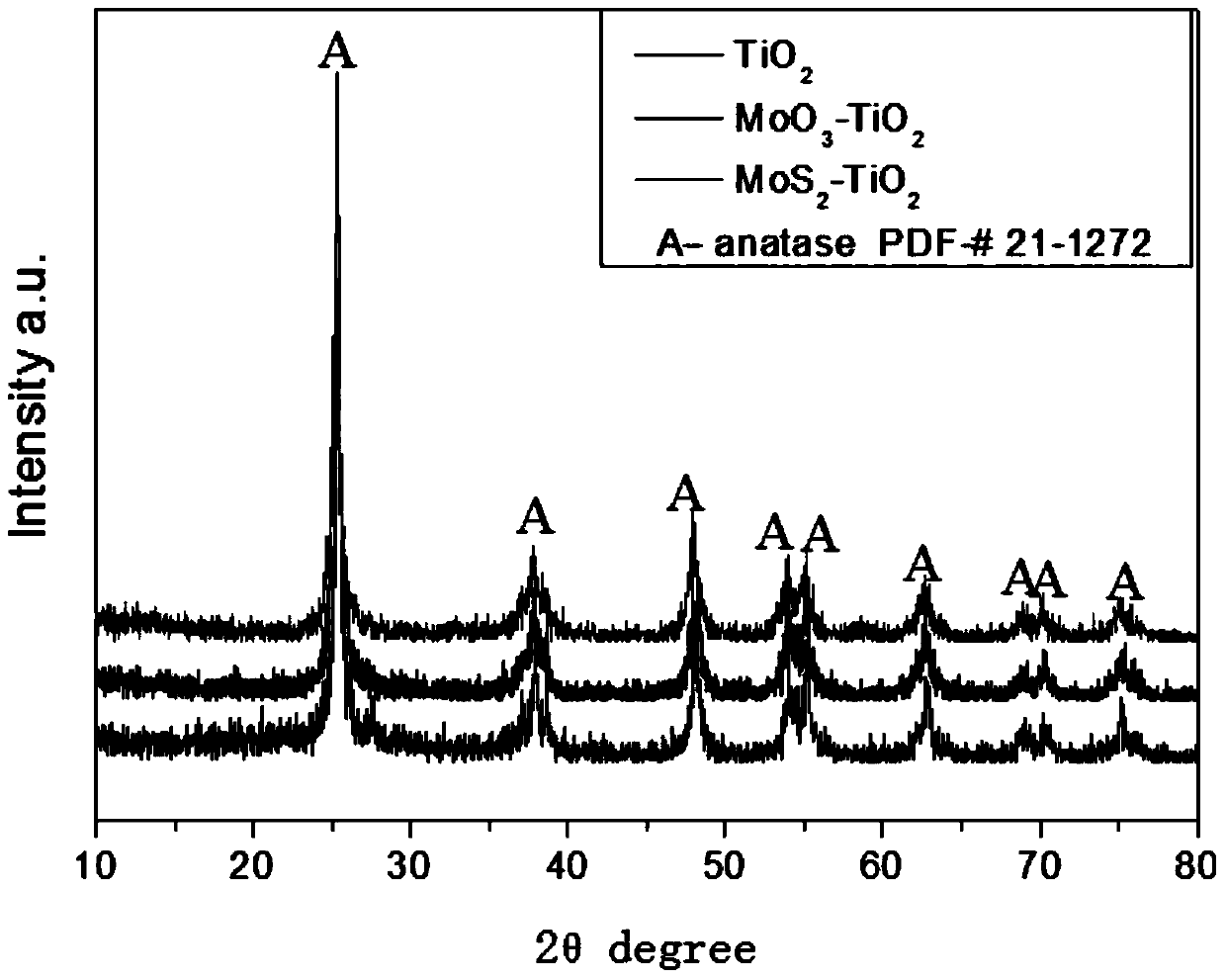

Embodiment 1

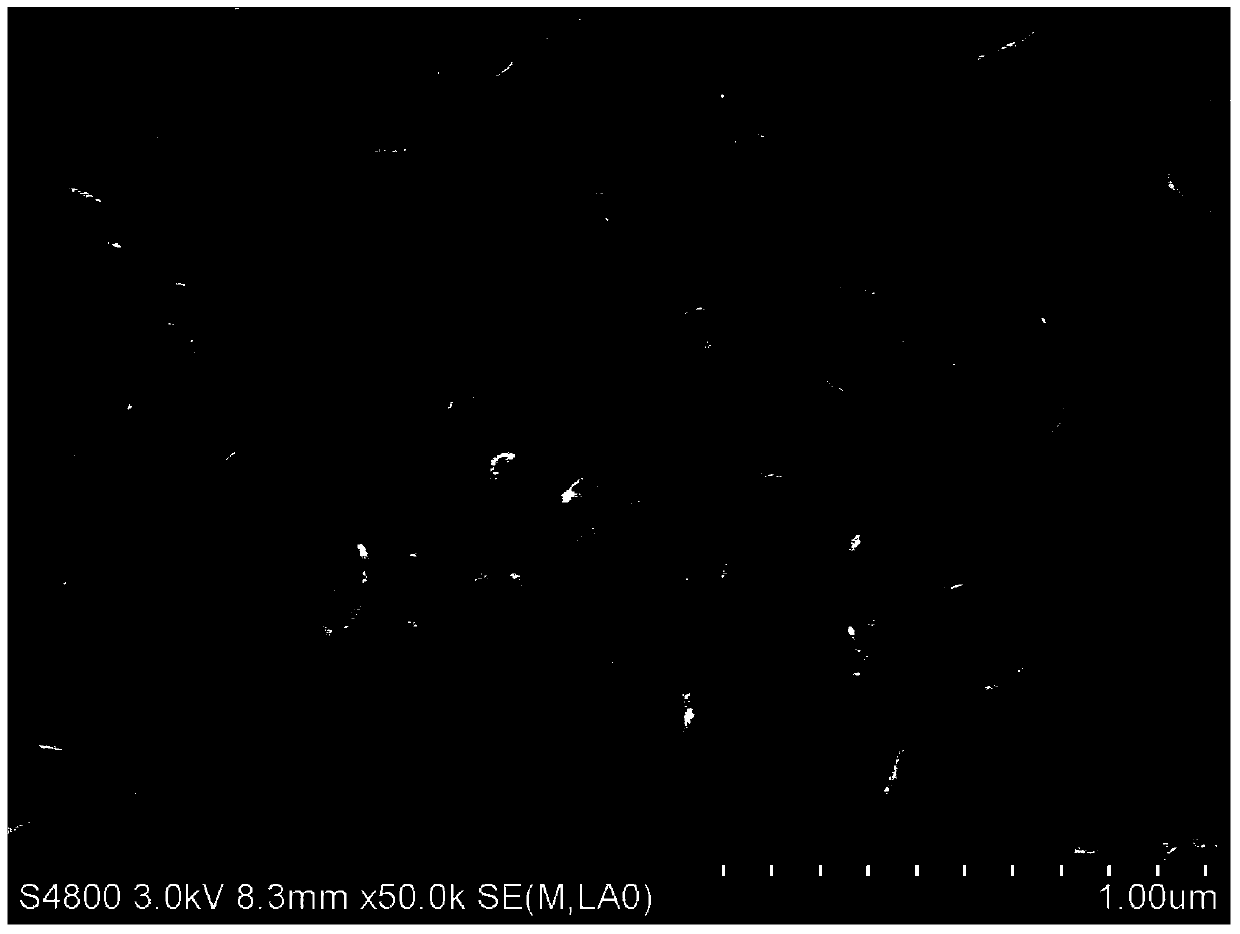

[0031] The first step is to prepare hexagonal thick layer MoS 2 : Take 0.25g of ammonium molybdate and dissolve it in water, adjust the pH value to 5, then weigh 2g of thiourea as the sulfur source, after the thiourea is dissolved, transfer the mixed solution to a 250mL hydrothermal kettle, and heat it at 240°C After the reaction was completed, the product was centrifuged, washed, and dried to obtain a hexagonal thick-layer MoS 2 .

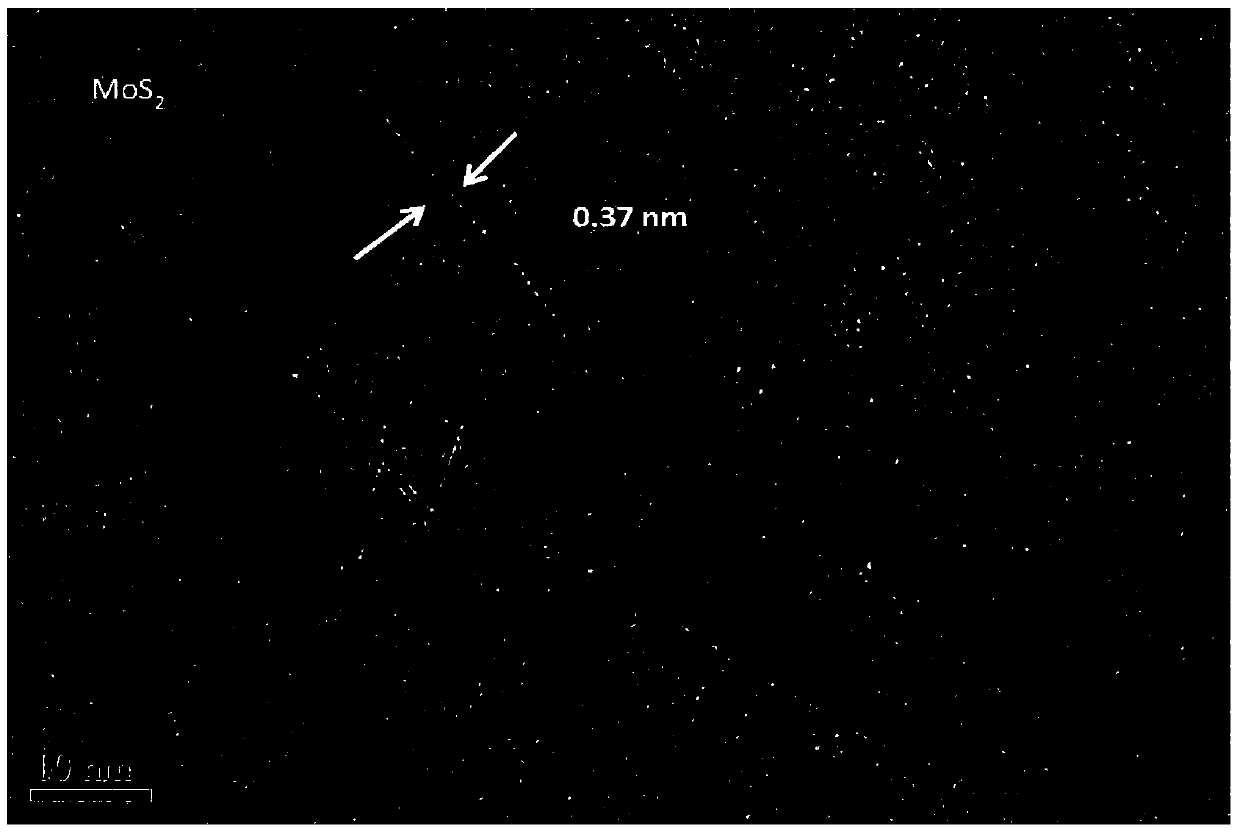

[0032] The second step is to prepare few-layer MoS 2 Aqueous solution: Take 0.5g of MoS synthesized above 2 Place in 10mL of 1.6M n-butyllithium solution, under N 2 Stir in a three-necked flask under protection for 48 hours, then filter the solution with 100mL of n-hexane in a simple glove box, transfer the black solid on the filter paper to a sealed container, and then inject 200mL of high-purity water, ultrasonic 1 hour, centrifuge, take the upper layer solution, and repeat the centrifugation until the solution has no precipitation, and a fe...

Embodiment 2

[0042] The first step is different from Example 1 in that the ammonium molybdate consumption is 0.3g, and thiourea is 2.5g.

[0043] In the second step, the difference from Example 1 is that MoS 2 The dosage is 0.2g, the n-butyllithium solution is 5mL, and the high-purity water is 300mL.

[0044] The third step is different from Example 1 in that the few-layer MoS 2 The amount of the solution is 10 mL, the amount of glucose is 7.5 g, the amount of ammonium fluotitanate is 1.5 g and dissolved in 50 mL of water.

Embodiment 3

[0046] The first step is different from Example 1 in that the ammonium molybdate consumption is 0.3g, and thiourea is 2.5g.

[0047] In the second step, the difference from Example 1 is that MoS 2 The dosage is 0.2g, the n-butyllithium solution is 5mL, and the high-purity water is 300mL.

[0048] The third step is different from Example 1 in that the few-layer MoS 2 The dosage of the solution is 10mL, the dosage of glucose is 7.5g, the dosage of ammonium fluotitanate is 1.5g and dissolved in 50mL of water, the pH of the mixed solution is adjusted to 5, the dosage of sulfur powder is 2g, and the curing time is 60min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com