Carboxylic butadiene-styrene latex and preparation method thereof

A technology of carboxylated styrene-butadiene latex and emulsion, which is applied in coatings, paper coatings, textiles and papermaking, etc. It can solve the problems of poor bonding strength and rheological properties of latex, poor water resistance and heat resistance, and poor leveling properties of coatings, etc. problems, to achieve the effect of eliminating the destruction of system stability, reducing energy consumption, and reducing side reactions

Active Publication Date: 2014-12-17

ZHUHAI JINJI CHEM

View PDF5 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Carboxylated styrene-butadiene latex is currently the most widely used latex in the production of coated paper, but these latexes have poor bonding strength and rheological properties and cannot meet the requirements; water resistance and heat resistance are relatively poor. After coating, The leveling performance of the coating is poor, resulting in uneven coating surface

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0035] Carboxylated styrene-butadiene latex is made from the following components by weight:

[0036]

Embodiment 2

[0038] Carboxylated styrene-butadiene latex is made from the following components by weight:

[0039]

[0040]

Embodiment 3

[0042] Carboxylated styrene-butadiene latex is made from the following components by weight:

[0043]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

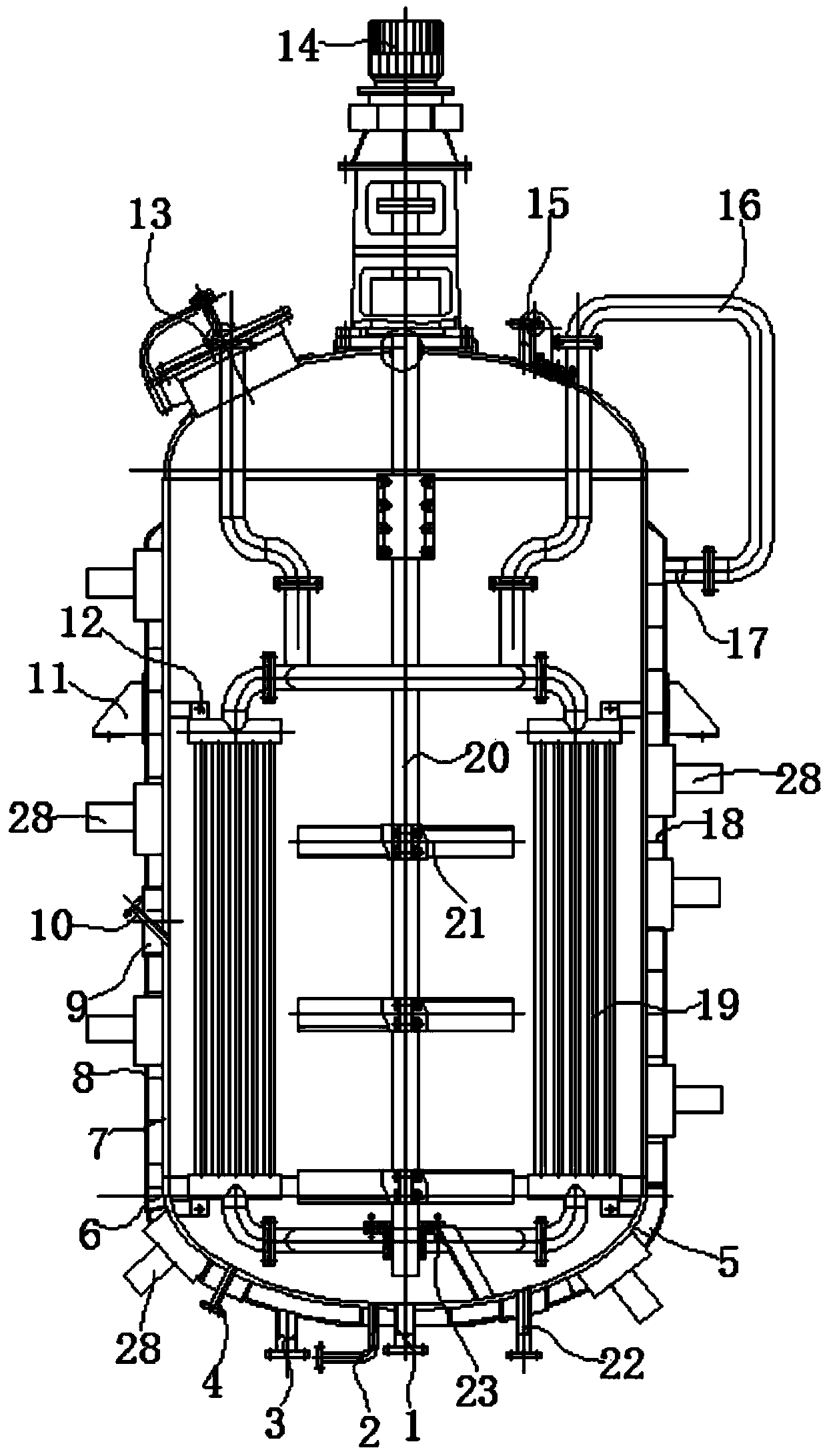

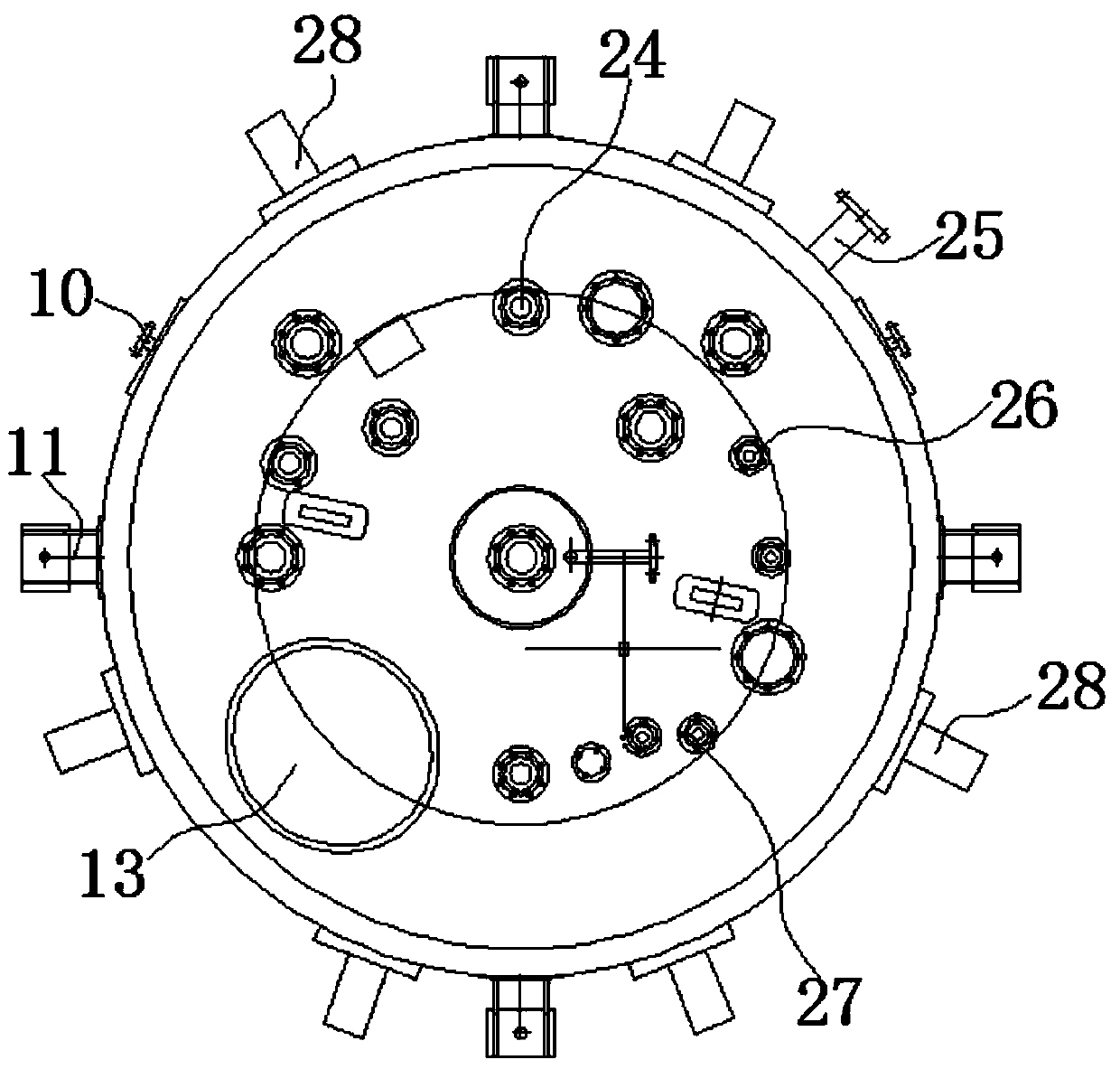

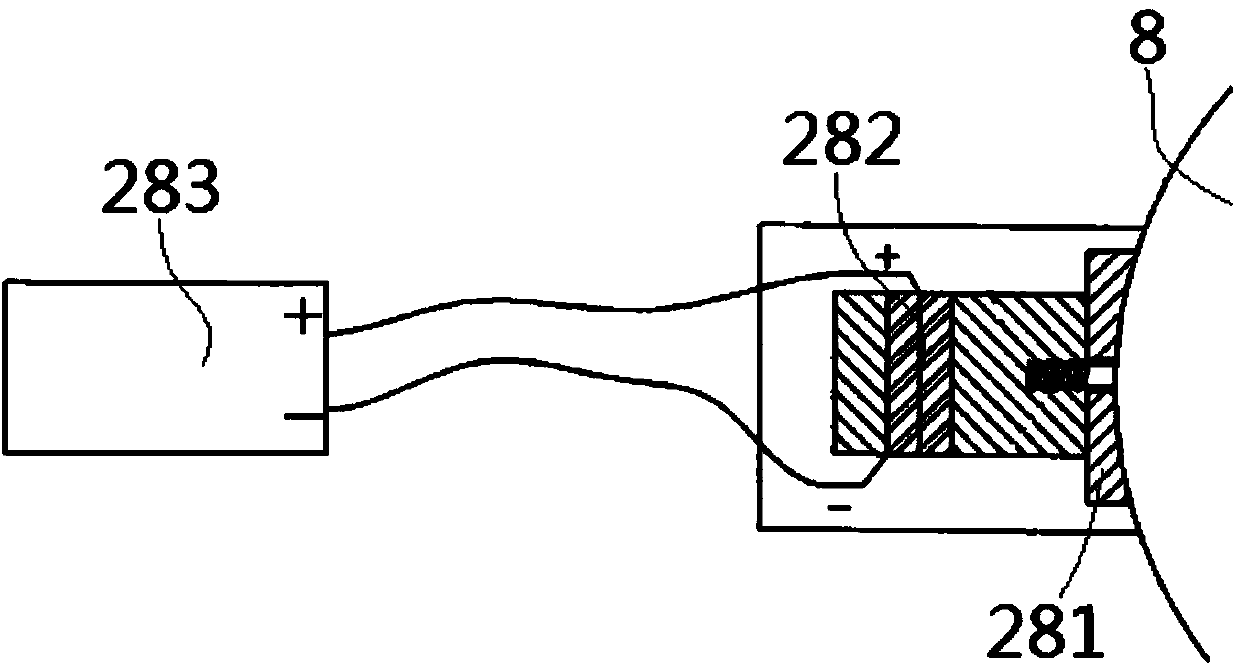

The invention discloses carboxylic butadiene-styrene latex. The carboxylic butadiene-styrene latex is prepared from the components of styrene, butadiene, acrylic acid, seed glue, an emulsifier, a functional monomer, sodium pyrophosphate, mercaptan and a chelating agent ammonium persulfate. The invention further discloses a preparation method of the carboxylic butadiene-styrene latex, wherein an ultrasonic irradiation device is arranged on the side wall of a reaction kettle, during reaction, the power is 600-1000W, the ultrasonic frequency is 60-80khz, and the power density of sound waves can be 2-5w / cm<2>. The carboxylic butadiene-styrene latex has the beneficial effects that the reaction efficiency can be effectively improved, the side reactions can be reduced, the monomer conversion rate can be increased to over 99%, the reaction time can be shortened by 4-7 hours, the recycled monomer amount can be reduced greatly, the energy consumption is reduced, the damage on the residual monomer to the system stability and the environmental protection can be eliminated to the greatest extent, the performances such as tensile strength, abrasion resistance, bonding strength, washing resistance, alkaline resistance and pollution resistance are excellent, and the mechanical stability and the chemical stability are excellent.

Description

technical field [0001] The invention relates to the technical field of carboxylated styrene-butadiene latex, in particular to carboxylated styrene-butadiene latex and a preparation method thereof. Background technique [0002] With the rapid development of social economy, the per capita paper consumption in our country is increasing, reaching about 60 kg per capita. According to the statistics of the China Paper Association, from 2004 to 2013, the average annual growth rate of paper and cardboard production was 8.26%, and the average annual growth rate of consumption was 6.74%. 101.1 million tons, an increase of -1.37% over the previous year. The consumption was 97.82 million tons, an increase of -2.65% over the previous year, and the per capita annual consumption was 72 kg (1.361 billion people). Among the main products, the production volume of newsprint is 3.6 million tons, accounting for 3.56% of the total output of paper and paperboard, and the consumption is 3.62 mil...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08F220/56C08F2/56C08F2/30C08F2/01C08F220/58C08F220/06D21H19/58C08F236/10C08F2/26D21H19/20

Inventor 蔡杨勇冯明东周建新余军生黄松贵

Owner ZHUHAI JINJI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com