Composite additive of automobile urea solution

A technology of compound additives and urea for vehicles, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of clogging of SCR system, poor dispersibility and unevenness of urea, etc., and achieve the effect of improving dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Denote the vehicle urea solution as S 0 , wherein the mass fraction of urea is 32.5%; then add four different composite additives S 1 , S 2 , S 3 and S 4 ; Change S in urea solution as shown in Table I 1 , S 2 , S 3 and S 4 The concentration of the surface tension was measured respectively and listed in Table I.

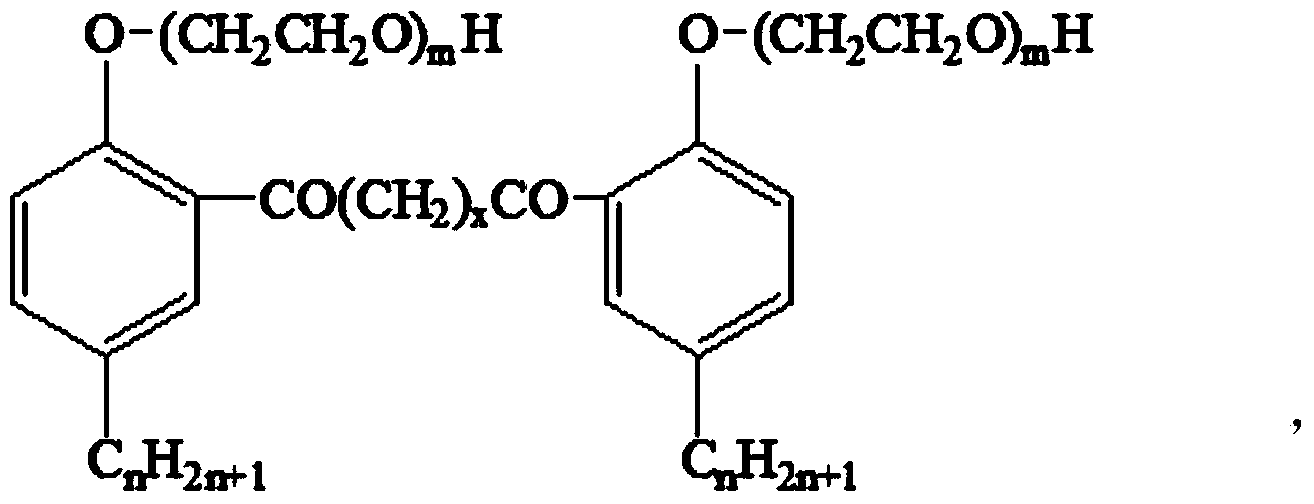

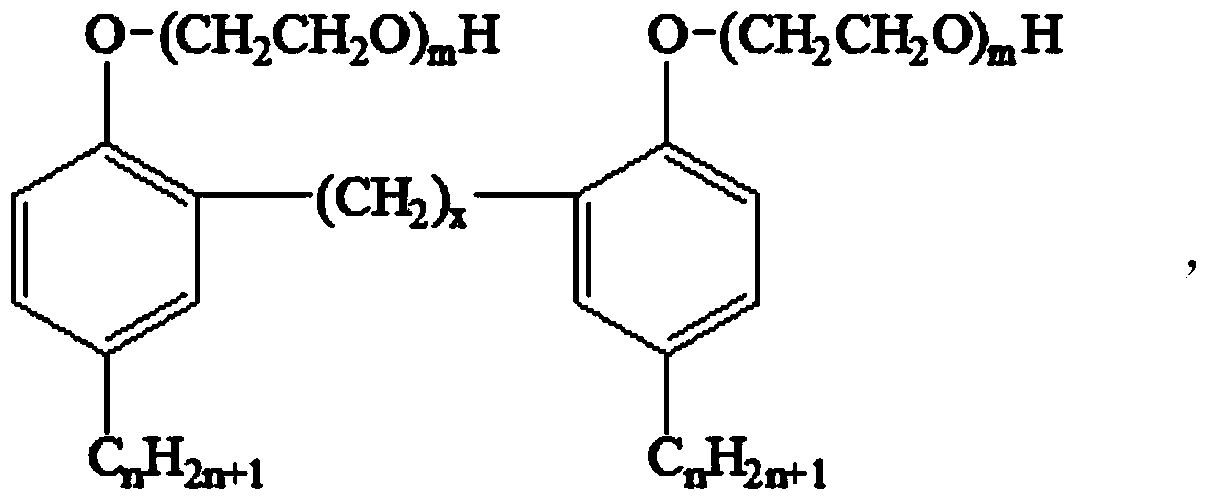

[0026] Where: S 1 , S 2 , S 3 and S 4 The structural formula is as follows:

[0027]

[0028]

[0029] Table Ⅰ The effect of Gemini surfactant on the surface tension of vehicle urea solution

[0030]

[0031] As can be seen from Table 1, as the surfactant concentration increases, the surface tension of the urea solution decreases, and the activity of the surfactant increases, and the low surface tension reduces the required energy barrier when the solution is dispersed, which is conducive to improving the dispersibility of the urea solution .

Embodiment 2

[0033] Use laser Doppler dynamic particle analyzer (PDA) to blank car urea solution and add composite additive S described in embodiment 1 respectively 1 , S 2 , S 3 or S 4 The vehicle urea solution was used for the spray characteristic test.

[0034] The mass concentration of urea in the urea solution is 32.5%, and the content of the composite additive is 100ppm.

[0035] Select five cross-sections on the spray axis, select five measuring points for each cross-section, and calculate the average diameter of the droplets. The experimental results are shown in Tables II-V.

[0036] It can be clearly seen from the data in the table that after the composite additive is added, the average diameter of the droplets on the cross section becomes significantly smaller.

[0037] Table Ⅱ Composite Additive S 1 Influence on spray characteristics

[0038]

[0039]

[0040] Table Ⅲ Composite Additive S 2 Influence on spray characteristics

[0041]

[0042] Table Ⅳ Composite ...

Embodiment 3

[0047] Prepare the urea solution for vehicles with a mass concentration of 32.5%, then add methyl silicone oil and 200ppm cetyl alcohol polyoxyethylene ether (the number of ethoxylates is 5) to it, and then add concentration S as described in Example 1 shown in Table VI 1 , S 2 , S 3 and S 4 .

[0048] The prepared solutions were applied to the bench test of the engine, and the test temperature was between 250°C and 280°C to determine the effect of the amount of compound additives added on the reduction of deposits in the SCR system. The results are listed in Table VI.

[0049] Table Ⅵ The effect of the addition amount of compound additives on the reduction of sediment

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com