Preparation method of heating element for ultrafine diamond synthesis

A heating element and diamond technology, which is applied in the field of preparation of heating elements for ultrafine diamond synthesis, can solve problems such as poor heat distribution uniformity, low temperature at both ends, and poor synthesis quality, and achieve simple structure, low cost, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

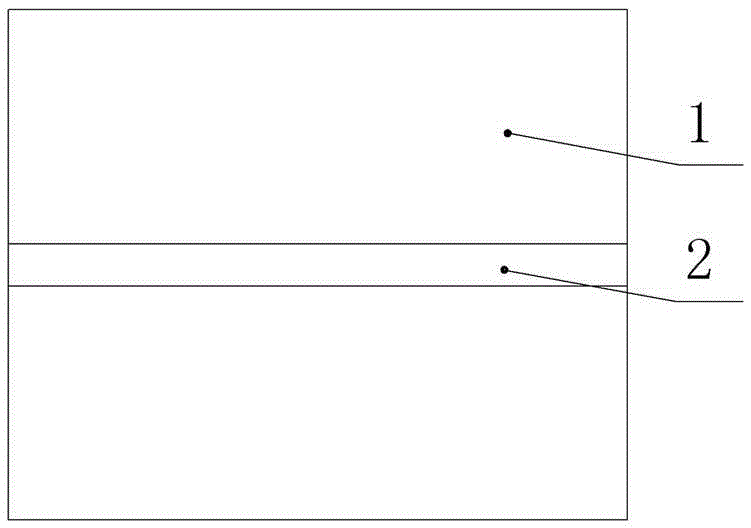

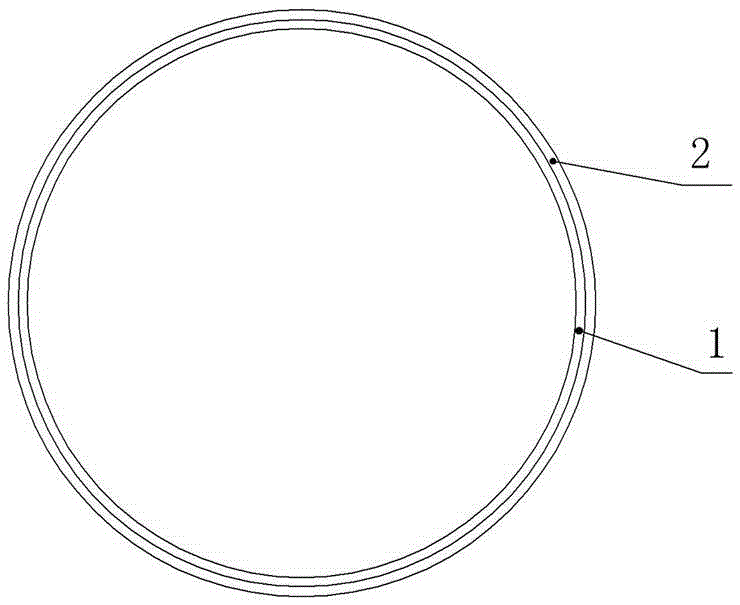

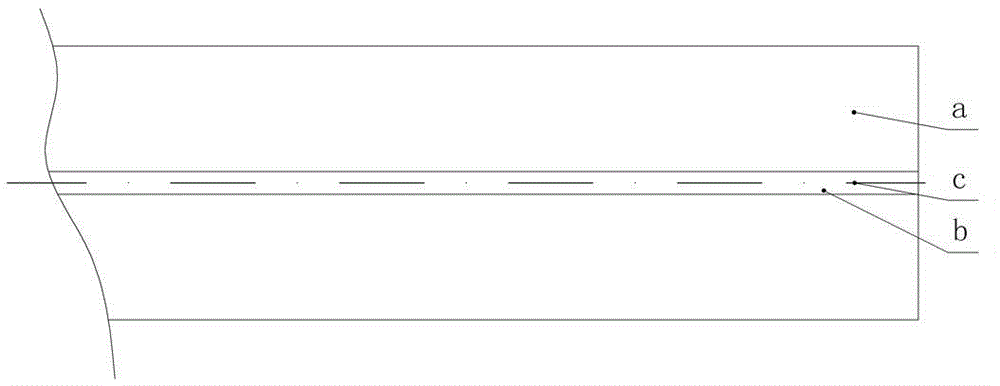

[0027] Embodiment 1: see figure 1 and figure 2 , the meanings represented by the labels in the figure are: 1. Heating element matrix, 2. Heating body. A heating element for ultrafine diamond synthesis, which is composed of a heating element base 1 and a heating element fixed on the outer wall of the heating element base 1, the heating element base 1 and heating element 2 are respectively cylindrical tubes with openings at the upper and lower ends Shaped structure, wherein the heating element 2 is symmetrically arranged around the center line of the axis of the heating element base 1.

[0028] In the above heating element for ultrafine diamond synthesis, the thickness of the heating element substrate 1 and the heating element 2 are respectively 0.1mm, the outer diameter of the heating element 2 is 42mm, and the height of the heating element substrate 1 is 42mm.

[0029] In the above-mentioned heating element for ultrafine diamond synthesis, the heating element base and the h...

Embodiment 2

[0041] Embodiment 2: Implementation 2 is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that the heating element substrate and the heating element of the heating element for ultrafine diamond synthesis are made of nickel-based alloy materials respectively, and the heating element The height of the substrate 1 is 46mm. The nickel-based alloy is composed of the following mass percentages of raw materials: iron content: 0.12%, chromium content: 29.5%, and the balance is nickel. The heat-resistant temperature of the nickel-based alloy is 1300°C. When preparing the above-mentioned heating element for ultrafine diamond synthesis, weigh various alloy components according to the raw material composition of the above-mentioned nickel-based alloy, put the alloy components into the vacuum furnace for alloy smelting, evacuate to 8Pa, heat up to 1480°C, smelt for 48min, and smelt The obtained alloy liquid is cast and cooled into an ingot; th...

Embodiment 3

[0043] Embodiment 3: Implementation 3 is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that the heating element substrate and the heating element of the heating element for ultrafine diamond synthesis are made of nickel-based alloy materials respectively, and the heating element The height of the substrate 1 is 48 mm. The nickel-based alloy is composed of the following mass percentages of raw materials: iron content: 0.55%, chromium content: 30%, and the balance is nickel. The heat-resistant temperature of the nickel-based alloy is 1350°C. When preparing the above-mentioned heating element for ultrafine diamond synthesis, weigh various alloy components according to the raw material composition of the above-mentioned nickel-based alloy, add the alloy components to the vacuum furnace for alloy smelting, evacuate to 8Pa, heat up to 1460°C, smelt for 49min, and smelt The obtained alloy liquid is cast and cooled into an ingot; then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com