Beneficiation method for high-tin-content multi-metal sulfide ores

A beneficiation method and multi-metal technology, applied in the direction of chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of excessive crushing of minerals, excessive ore slime, low recovery rate of tin minerals, etc., and achieve the improvement of copper recovery rate, The effect of improving tin recovery rate and improving comprehensive recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Taking a high-tin polymetallic sulfide ore in Yunnan as an example for mineral processing, the tin-containing sulfide ore in Yunnan includes the following mass percentage components: tin 0.56wt.%, copper 0.24wt.wt.%, lead 0.15wt.%, zinc 0.91 wt.%, Sulfur 19.56wt.%, Cassiterite 0.54wt.%, Zorotite 0.05wt.%, Chalcopyrite 0.62wt.%, Ferric sphalerite 0.72wt.%, Pyrrhotite 51.04wt.% , siderite 1.66wt.%, quartz 8.43wt.%, carbonate minerals 7.62wt.%, biotite 6.93wt.%, chlorite 3.87wt.%.

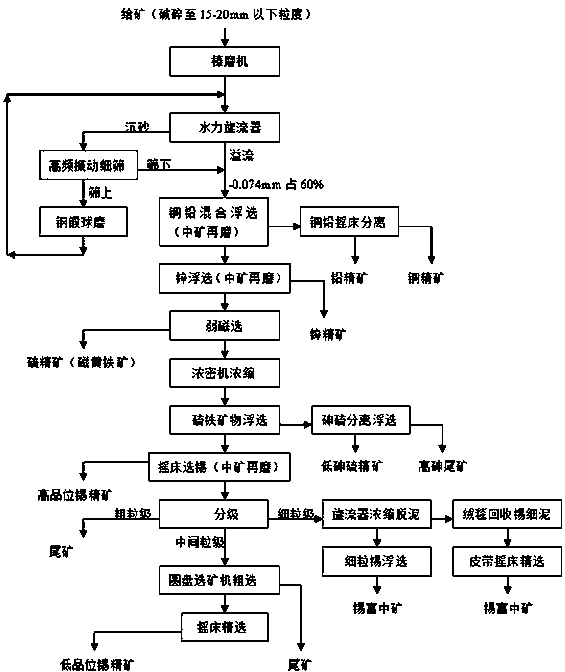

[0020] Such as figure 1 Shown, the beneficiation method of this high-tin polymetallic sulfide ore, its concrete steps are as follows:

[0021] Step 1: First, crush the high-tin polymetallic sulfide ore raw ore to a particle size below 15-20mm, then put the crushed high-tin polymetallic sulfide ore into a rod mill for open-circuit grinding, and the rod mill discharges the ore to be classified by a hydrocyclone Overflow and sand settling, the overflow enters copper-lead mixed flotation, sand se...

Embodiment 2

[0027] Taking a high-tin polymetallic sulfide ore in Guangxi as an example for mineral processing, the high-tin polymetallic sulfide ore in Guangxi includes the following mass percentage components: tin 0.73wt.%, lead 0.79wt.%, zinc 1.5wt.%, sulfur 18.2 wt.%, the raw ore cassiterite intercalation particle size is between 8 and 180 microns, and the tin metal distribution of tin-containing particles with a dissociation degree of more than 90% when broken to less than 3 mm is 90%.

[0028] Such as figure 1 Shown, the beneficiation method of this high-tin polymetallic sulfide ore, its concrete steps are as follows:

[0029] Step 1: First, crush the high-tin polymetallic sulfide ore raw ore to a particle size below 15-20mm, then put the crushed high-tin polymetallic sulfide ore into a rod mill for open-circuit grinding, and the rod mill discharges the ore to be classified by a hydrocyclone Overflow and sand settling, the overflow enters copper-lead mixed flotation, sand settling i...

Embodiment 3

[0034] Taking a high-tin polymetallic sulfide ore in Guangxi as an example for mineral processing, the high-tin polymetallic sulfide ore in Guangxi includes the following mass percentage components: tin 1.53wt.%, lead 0.78wt.%, antimony 0.69wt.%, zinc 2.5 wt.%, sulfur 17.2wt.%, raw ore cassiterite intercalation particle size is relatively coarse, between 35-250 microns, and the tin metal distribution of tin-containing particles with a dissociation degree of more than 85% when broken to less than 3 mm reaches 90%.

[0035] Such as figure 1 Shown is the beneficiation method of this high-tin polymetallic sulfide ore, and its concrete steps are as follows:

[0036] Step 1: First, crush the high-tin polymetallic sulfide ore raw ore to a particle size below 15-20mm, then put the crushed high-tin polymetallic sulfide ore into a rod mill for open-circuit grinding, and the rod mill discharges the ore to be classified by a hydrocyclone Overflow and sand settling, the overflow enters co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com