Method for preparing fine spherical stainless steel powder

A stainless steel powder and spherical technology, applied in the field of preparation of fine spherical stainless steel powder, can solve the problems of restricting the popularization and application of gas atomized stainless steel powder, affecting the performance of stainless steel products, coarse powder particle size, etc., achieving easy automatic control and widening the scope of application , the effect of uniform distribution of elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the fine spherical stainless steel powder of the present invention comprises the following steps:

[0019] First, directly select 316L stainless steel powder or use C, Si, S, P, Fe, Cr, Ni, Mo, Mn elements to form an alloy in proportion. Since it is possible to select appropriate proportions of elements to prepare raw materials according to material requirements, the element design can be carried out according to material requirements, which broadens the scope of application of raw materials, and can choose relatively cheap and cheap raw materials.

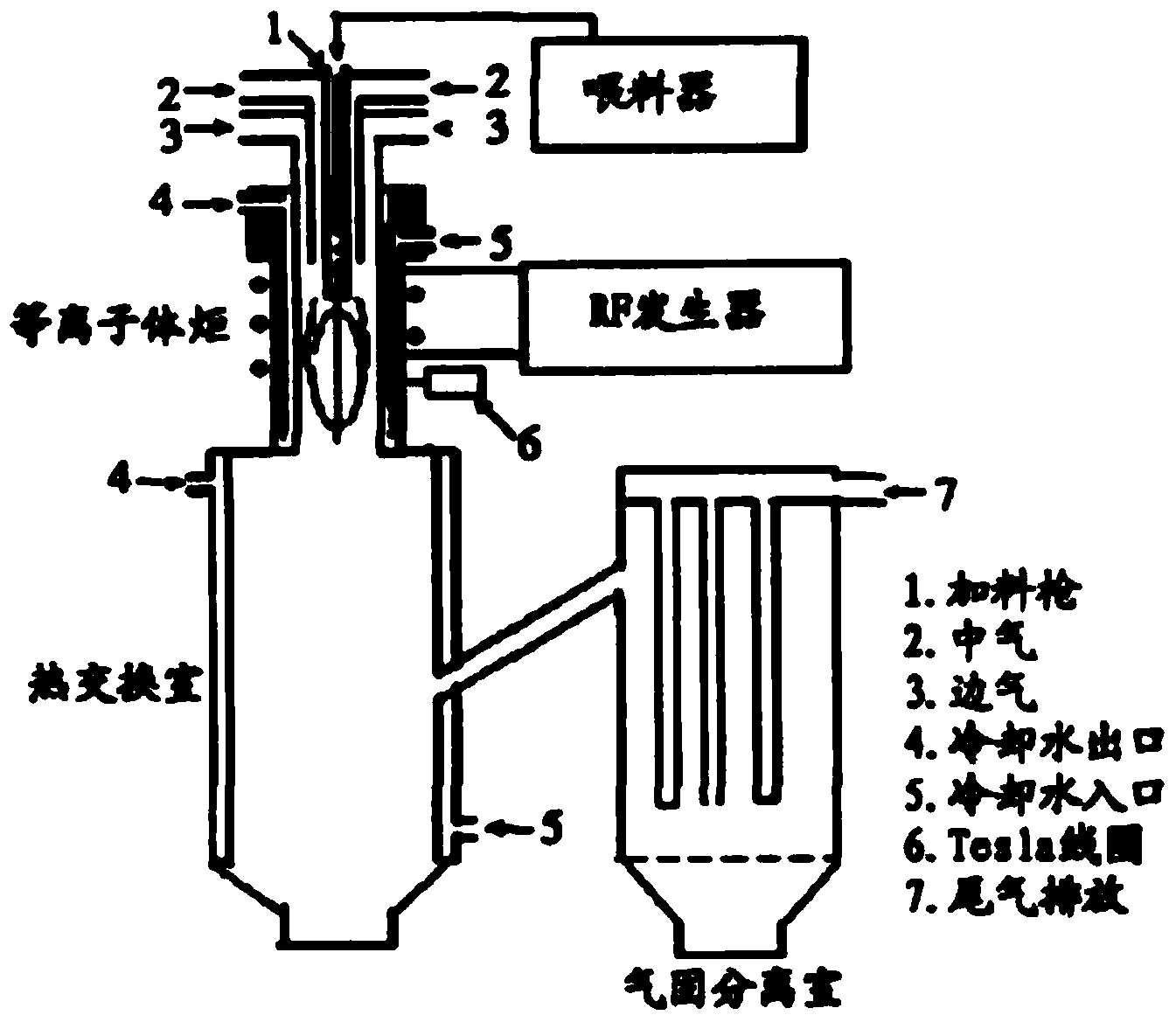

[0020] Then use hydrogen or argon as the carrier gas to send the above-mentioned alloy feed or 316L stainless steel powder into the plasma torch for vaporization and melting to form an alloy body. The high-frequency plasma equipment used in this step is as figure 1 As shown, it mainly includes feeder, plasma torch, RF generator (radio frequency generator), heat exchange chamber and gas-solid separ...

Embodiment 1

[0024] This embodiment provides a preparation method of fine spherical stainless steel powder, comprising the following steps:

[0025] (a) Select 316L stainless steel powder;

[0026] (b) Use argon as the carrier gas to send the stainless steel powder into the plasma torch for vaporization and melting to form an alloy body. The flow rate of the carrier gas is 0.5m 3 / h, the feed rate is 5g / min, and the power of the plasma torch is 50kW, and the flow rate of the generated gas is 1m 3 / h of argon, side gas flow rate 1m 3 / h of argon, the pressure is a negative pressure of 200mm Hg;

[0027] (c) Introduce the alloy body into a heat exchange chamber with a temperature of 150°C, and the heat exchange adopts a flow rate of 1m 3 / h of argon;

[0028] (d) Introduce the fine spherical stainless steel powder into the gas-solid separation chamber to collect the solid powder.

Embodiment 2

[0030] This embodiment provides a preparation method of fine spherical stainless steel powder, comprising the following steps:

[0031] (a) Select C, Si, S, P, Fe, Cr, Ni, Mo, and Mn elements to form alloys in proportion, among which C≤0.03%, Si≤1%, Mn≤2%, P≤0.035% , S≤0.03%, Ni is 10%~14%, Cr is 16%~18%, Mo is 2%~3%, and the balance is Fe (mass ratio);

[0032] (b) Use hydrogen as the carrier gas to send the alloy material into the plasma torch for vaporization and melting to form an alloy body. The flow rate of the carrier gas is 5m 3 / h, the feed rate is 100g / min, and the power of the plasma torch is 5kW, and the flow rate of the generated gas is 3m 3 / h of argon, the side gas flow rate is 20m 3 / h of argon, the pressure is a negative pressure of 50mm Hg;

[0033] (c) Lead the alloy body into a heat exchange chamber with a temperature of 150 °C, and the heat exchange adopts a flow rate of 1 m 3 / h of hydrogen;

[0034] (d) Introduce the fine spherical stainless steel p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com