Multi-head zinc oxide nanorods and preparation method thereof

A technology of zinc oxide nanorods and nanorods, which is applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., to achieve an effect that is beneficial to performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

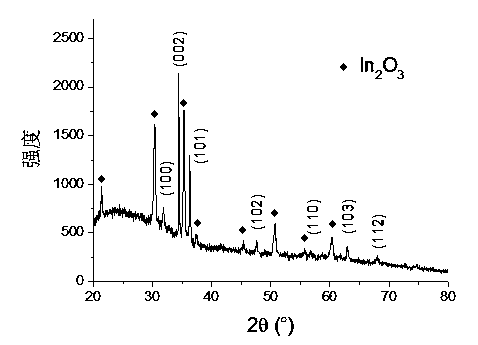

Image

Examples

Embodiment 1

[0015] Embodiment one: Electrochemical deposition process at 0.01 mol / L Zn(NO 3 ) 2 It was carried out in aqueous solution, the power source used was a two-electrode system, the voltage was constant at 2 V, the temperature was constant at 75 °C, and the deposition time was 30 min. The ITO glass substrate is connected to the cathode, and the anode is made of pure platinum, and the two electrodes are kept parallel with a distance of 2 cm. After the deposition was completed, all samples were washed repeatedly with deionized water to remove residual solution ions on the samples. Afterwards, the samples were placed in an air atmosphere heat treatment furnace for annealing at 150 °C. The electrodeposited ZnO nanorod array sample was placed in an ion sputtering device, the sputtering source was a pure ZnO sheet, the sputtering current was adjusted to 50 mA, and the sputtering was performed for 90 s. Then, the sample after sputtering the seed layer was placed in zinc nitrate with...

Embodiment 2

[0017] Embodiment two: Electrochemical deposition process at 0.01 mol / L Zn(NO 3 ) 2 It was carried out in aqueous solution, the power supply used was a two-electrode system, the voltage was constant at 2 V, the temperature was constant at 75 °C, and the deposition time was 40 min. The ITO glass substrate is connected to the cathode, and the anode is made of pure platinum, and the two electrodes are kept parallel with a distance of 2 cm. After the deposition was completed, all samples were washed repeatedly with deionized water to remove residual solution ions on the samples. Afterwards, the samples were placed in an air atmosphere heat treatment furnace for annealing at 150 °C. The electrodeposited ZnO nanorod array sample was placed in an ion sputtering device, the sputtering source was a pure ZnO sheet, the sputtering current was adjusted to 100 mA, and the sputtering was performed for 60 s. Then, the sample after sputtering the seed layer was placed in zinc nitrate wit...

Embodiment 3

[0019] Embodiment three: Electrochemical deposition process at 0.01 mol / L Zn(NO 3 ) 2 It was carried out in aqueous solution, the power supply used was a two-electrode system, the voltage was constant at 2 V, the temperature was constant at 95 °C, and the deposition time was 60 min. The FTO glass substrate is connected to the cathode, and the anode is made of pure platinum, and the two electrodes are kept parallel with a distance of 2 cm. After the deposition was completed, all samples were washed repeatedly with deionized water to remove residual solution ions on the samples. Afterwards, the samples were placed in an air atmosphere heat treatment furnace for annealing at 150 °C. The electrodeposited ZnO nanorod array sample was placed in an ion sputtering device, the sputtering source was a pure ZnO sheet, the sputtering current was adjusted to 150 mA, and the sputtering was performed for 40 s. Then, the sample after sputtering the seed layer was put into zinc nitrate wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com