High-viscosity self-crosslinking LED package gum resin and preparation method thereof

A technology of LED encapsulation and self-crosslinking, applied in the direction of adhesives, etc., can solve the problems of poor compatibility and uneven mixing, and achieve the effects of short preparation route, simple preparation process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

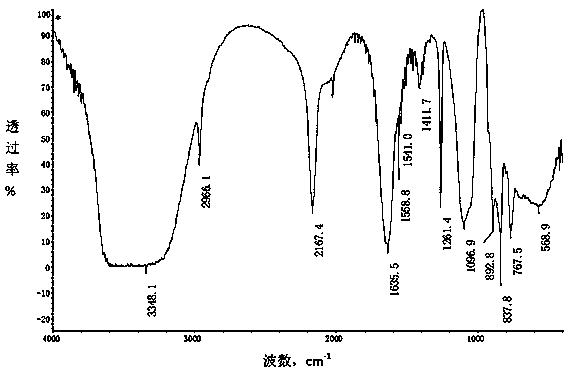

Image

Examples

Embodiment 1

[0038] A high-viscosity self-crosslinking LED encapsulation resin, calculated in parts by weight, its raw material composition and content are as follows:

[0039] 100 parts of phenyltrimethoxysilane

[0040] Diphenyldimethoxysilane 100 parts

[0041] Hydrogen ring body 20 parts

[0042] Vinyl double head 30 parts

[0043] 20 parts of distilled water

[0044] Solvent 100 parts

[0045] 3 parts catalyst;

[0046] Described solvent is toluene;

[0047] The catalyst is an aqueous sulfuric acid solution with a concentration of 70% by mass.

[0048] The above-mentioned preparation method of a high-viscosity self-crosslinking type LED encapsulation resin, the steps are as follows:

[0049]Add phenyltrimethoxysilane, diphenyldimethoxysilane, hydrogen-containing cyclic body, vinyl double head, distilled water, solvent and catalyst into the container in sequence, raise the temperature to 60°C, keep stirring for 4 hours, and then Raise the temperature to 100°C, react at a consta...

Embodiment 2

[0063] A high-viscosity self-crosslinking LED encapsulation resin, calculated in parts by weight, its raw material composition and content are as follows:

[0064] 105 parts of phenyltrimethoxysilane

[0065] 120 parts of diphenyldimethoxysilane

[0066] 10 parts of hydrogen-containing ring body

[0067] Vinyl double header 50 parts

[0068] 60 parts of distilled water

[0069] Solvent 200 parts

[0070] Catalyst 5 parts;

[0071] Described solvent is benzene;

[0072] The catalyst is an aqueous solution of hydrochloric acid with a concentration of 38% by mass.

[0073] The above-mentioned preparation method of a high-viscosity self-crosslinking type LED encapsulation resin, the steps are as follows:

[0074] Add phenyltrimethoxysilane, diphenyldimethoxysilane, hydrogen-containing cyclic body, vinyl double head, distilled water, solvent and catalyst into the container in sequence, raise the temperature to 40°C, keep stirring for 8 hours, and then Raise the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com