Inorganic nano-composite anion exchange membrane and preparation method thereof

An anion exchange membrane and nanocomposite technology, applied in the field of inorganic nanocomposite anion exchange membrane and its preparation, can solve the problems of low membrane conductivity, uncontrollable size and shape, hindering organic membrane ion channels, etc., and achieve simple preparation method , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention discloses a preparation method of a nanocomposite anion exchange membrane, which comprises the following steps:

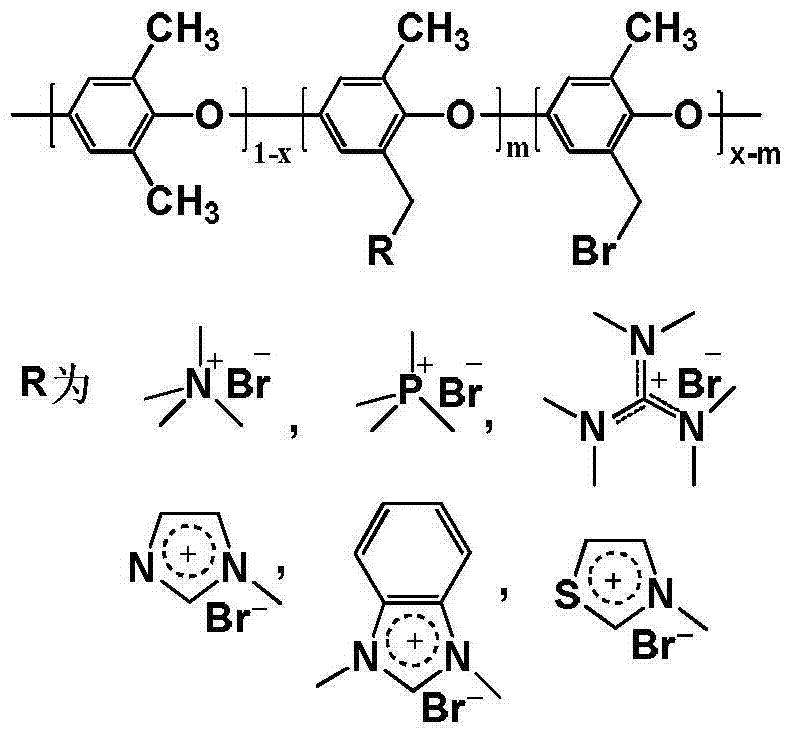

[0032] Dissolving brominated polyphenylene ether in the first solvent, adding a basic functional reagent to react to obtain a positively charged brominated polyphenylene ether, the basic functional reagent is trimethylamine, trimethylphosphine, guanidinium compounds, N-methylimidazole, benzimidazole and thiazole;

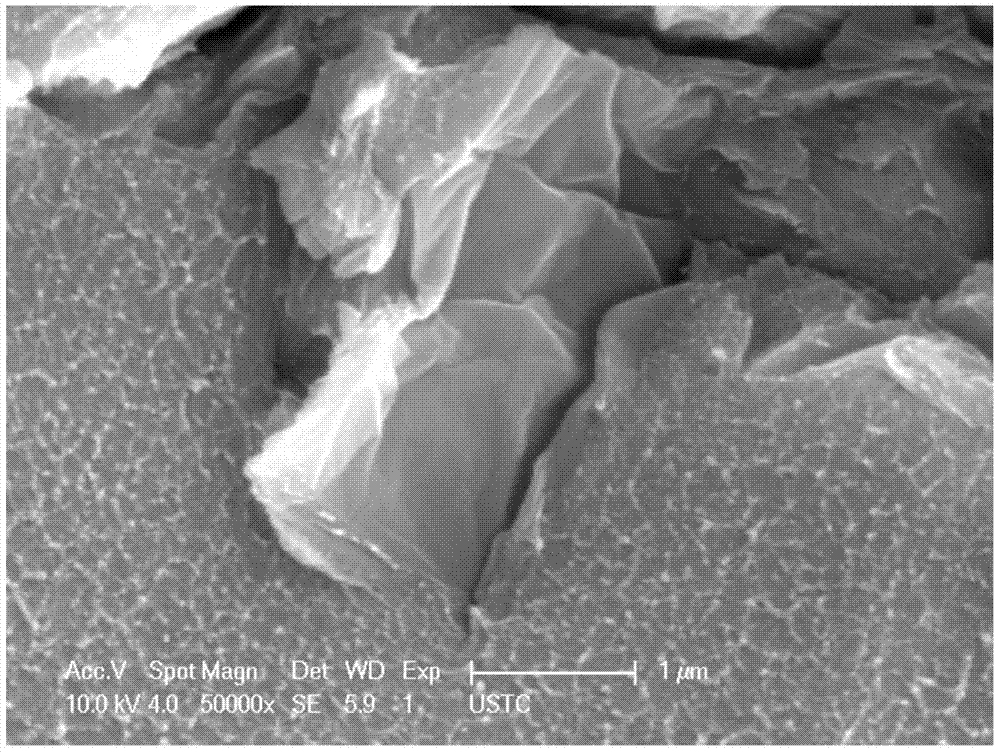

[0033] adding graphene oxide into the second solvent, and ultrasonicating to obtain the stripped graphene oxide solution;

[0034] The positively charged brominated polyphenylene ether is dissolved in the graphene oxide solution and stirred to obtain a casting liquid, and the casting liquid is cast into a film to obtain an anion exchange membrane.

[0035] In the above preparation process, the present invention firstly prepares positively charged brominated polyphenylene ether, and prepares a graphene oxide solution by ultrasonic st...

specific Embodiment approach

[0052] In order to further illustrate the technical solution of the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only for further illustrating the features and advantages of the present invention, rather than limiting the claims of the present invention.

[0053] The solvents used in the examples of the present invention were all purchased from Sinopharm Group, and the basic functional reagents and graphene oxide were purchased from Anaiji Chemical.

Embodiment 1

[0055] 1. Preparation of positively charged brominated polyphenylene ether: Dissolve 1 g of brominated polyphenylene ether with a bromination degree of 57.8% in 4 mL of N-methylpyrrolidone, stir well, and add 600 μL of N-methylpyrrolidone after the polymer is completely dissolved. -Methylimidazole, wherein the molar ratio of N-methylimidazole to brominated poly(phenylene ether) bromomethyl is 0.863:1, and reacted with magnetic stirring at 30° C. for 10 h. The above reaction solution was poured into 50 mL of water to precipitate the polymer, and then washed with water three times to remove unreacted N-methylimidazole, and vacuum-dried at 60°C to obtain positively charged brominated polyphenylene ether.

[0056] 2. Configuration of graphene oxide solution: put 0.5g of graphene oxide with a degree of oxidation of 32.5% in 100mL of dimethyl sulfoxide, ultrasonicate at 25°C for 1.5h, and fully peel off graphene oxide to obtain 0.5mg / mL of graphene oxide solution in dimethyl sulfox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com