Liquefaction method of waste polyisocyanurate foam and liquefied polyol prepared therefrom

A technology of polyisocyanurate and foam plastics, which is applied in the field of liquefied polyols, can solve the problems of low ring-opening efficiency and achieve the effects of uniform material system, good liquefaction effect, and good formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

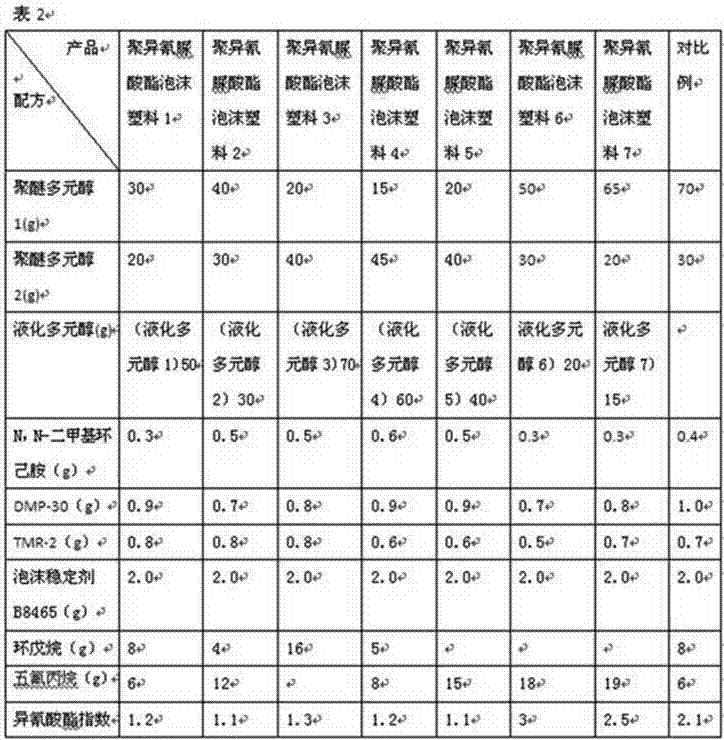

Embodiment 1

[0032] 180 grams of ethylene glycol, H 4 SiW 12 o 40 / SiO 2 (H 4SiW 12 o 40 with SiO 2 The mass ratio is 36%) 3.3 grams, 100 grams of polyisocyanurate foam fragments are added to a 2L stainless steel reactor with a condensation reflux device, stirred and heated to 150 ° C, and then 200 grams of polyisocyanurate foam The fragments were added to the reactor twice (120 grams at a time, 80 grams at a time), nitrogen gas was introduced, and the reaction was kept at normal pressure for 5 hours; 30 grams of diethanolamine was added, and the temperature was raised to 160 °C with stirring, and the pressure of the reaction kettle was filled with nitrogen gas. 0.5MPa, heat preservation reaction for 5h, filter out the catalyst, and obtain liquefied polyol 1.

[0033] The above-mentioned liquefied polyol 1 product index: hydroxyl value 560mgKOH / g, acid value 1.4mgKOH / g, viscosity 12500mPa·s (@25℃), moisture 0.11%.

Embodiment 2

[0035] 200 grams of glycerol, H 3 PW 12 o 40 / SiO 2 (H 3 PW 12 o 40 with SiO 2 The mass ratio is 30%) 4.5 grams, 120 grams of polyisocyanurate foam fragments are added to a 2L stainless steel reactor with a condensing reflux device, stirred and heated to 170 ° C, and then 230 grams of polyisocyanurate foam Add the fragments into the reactor twice (one time 120 grams, one time 110 grams), feed nitrogen, normal pressure, keep warm for 5 hours; add 30 grams of triethanolamine, 5 grams of monoethanolamine, and 10 grams of triisopropanolamine, stir Raise the temperature to 170° C., fill the reactor with nitrogen so that the pressure of the reactor is 0.8 MPa, keep the reaction for 6 hours, filter out the catalyst, and obtain liquefied polyol 2.

[0036] The above-mentioned liquefied polyol 2 product indicators: hydroxyl value 436mgKOH / g, acid value 1.0mgKOH / g, viscosity 8500mPa·s (@25℃), moisture 0.10%.

Embodiment 3

[0038] 120 grams of dipropylene glycol, 40 grams of trimethylolpropane, H 4 SiMo 12 o 40 / C (H 4 SiMo 12 o 40 The mass ratio to activated carbon is 39%) 5.0 grams, 110 grams of polyisocyanurate foam fragments into a 2L stainless steel reactor with a condensing reflux device, stirred and heated to 150 ° C, and then 210 grams of polyisocyanurate The foam plastic fragments were added into the reactor three times (70 grams each time), nitrogen was introduced, and the pressure was maintained for 5 hours; 15 grams of diisopropanolamine was added, and the temperature was raised to 160 °C with nitrogen filling to make the pressure of the reactor 0.8MPa, keep the temperature for 7 hours, filter out the catalyst, and obtain liquefied polyol 3.

[0039] The above liquefied polyol 3 product indicators: hydroxyl value 650mgKOH / g, acid value 1.5mgKOH / g, viscosity 35500mPa·s (@25℃), moisture 0.15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com