Super-white environmental-friendly toughened glass ink and preparation method thereof

A tempered glass ink, environmentally friendly technology, applied in inks, household appliances, applications, etc., can solve the problems of coating peeling, poor printing adaptability, physical injury to printing workers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

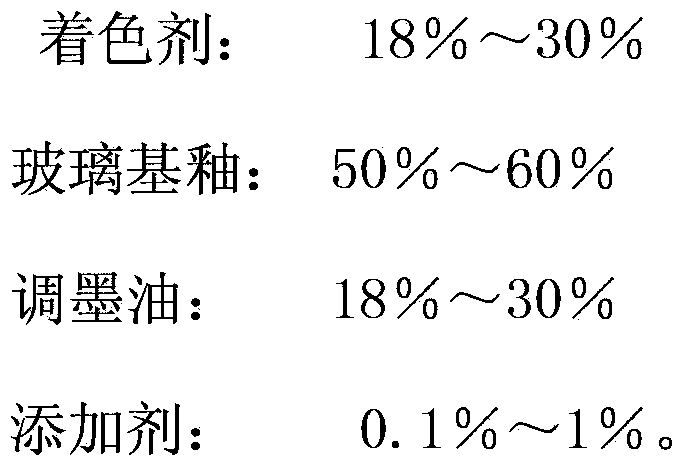

[0025] A kind of ultra-white environment-friendly toughened glass ink of the present invention, each component that comprises and its weight percentage are as follows:

[0026]

[0027] The coloring agent is mainly zinc oxide or titanium dioxide.

[0028] Glass-based glazes mainly include boron oxide, silicon oxide, zinc oxide, sodium oxide, potassium oxide, aluminum oxide and zirconium oxide.

[0029] The glass-based glaze consists of 35% boron oxide, 39% silicon oxide, 5% zinc oxide, 5% sodium oxide, 5% potassium oxide, 5% aluminum oxide and 1% zirconium oxide.

[0030] Varnish mainly includes turpentine, turpentine ester, rosin resin and ethyl cellulose.

[0031] The varnish includes 30% turpentine, 30% turpentine ester, 20% rosin resin, and 20% ethyl cellulose.

[0032] Additives include silicone defoamers.

[0033] A kind of preparation method of ultra-white environment-friendly tempered glass ink of the present invention is:

[0034] First, prepare glass-based gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com