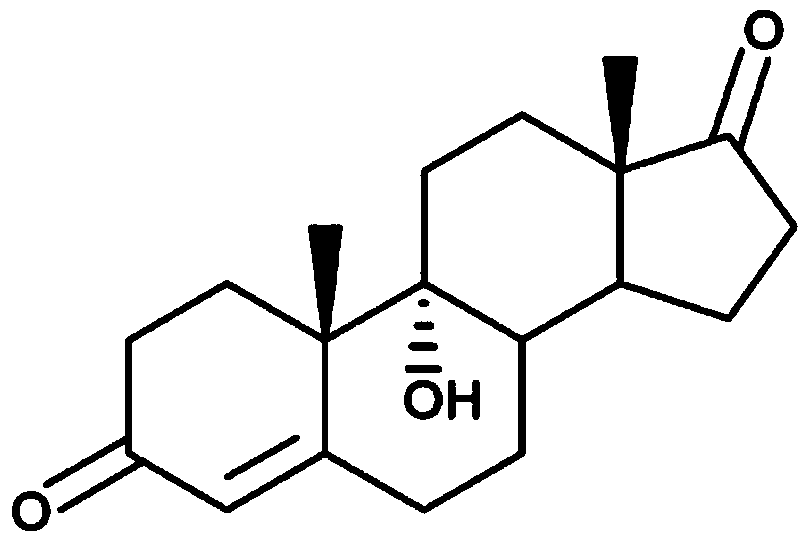

Method for producing 9-alpha-hydroxyandrostenedione by microbial fermentation

A technology for hydroxyandrostenedione and microbial fermentation, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as pollution and unsuitability for industrial production of 9α-OHAD, and achieve simple extraction and high yield High, low environmental pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Strain propagation: ZS3-9α was prepared into a bacterial concentration of 10 7 -10 9 Bacterial suspension of individual / ml, insert in the seed tank of seed culture medium with 5%-10% inoculum size afterwards and cultivate, and seed culture medium comprises: glucose 8g / L, MgSO 4 ·7H 2 O 0.8g / L, (NH 4 ) 2 Fe(SO 4 ) 2 ·6H 2 O 0.02g / L, CaCO 3 5.5g / L and citric acid 1.0g / L, the pH of the seed medium is 7.0;

[0038] Fermentation transformation: OD of seed liquid in the seed tank 600 When it is 15-20, insert it into the transformation medium with 20% inoculum size for cultivation, and the fermentation medium includes: glucose 30g / L, peptone 15g / L, bean cake powder 25g / L, MgSO 4 ·7H 2 O 0.5g / L, (NH 4 ) 2 Fe(SO 4 )2·6H 2 O 0.06g / L, CaCO 3 4.5g / L, 3.0g / L citric acid, pH of the fermentation medium is 7.0; wherein, the substrate phytosterol is added to the prepared basic fermentation medium with a mass fraction of 2.0%. The transformation culture conditions are as ...

Embodiment 2

[0042] In Example 1, the inoculum amount of strains during fermentation transformation was changed to 30%, and the transformation culture conditions were changed to: temperature 32°C, tank pressure 0.05MPa, stirring 150-200rpm, dissolved oxygen 30%, cycle 100h.

[0043] The test result is: the final conversion rate of 9α-OH AD is 93.2%.

Embodiment 3

[0045] Change the inoculum amount of the bacterial classification to 50% during fermentation transformation in Example 1, change the mass fraction of phytosterols to 3.0%, and change the transformation culture conditions to: temperature 32°C, tank pressure 0.05MPa, stirring 150-200rpm, cycle 120h .

[0046] The test result is: the final conversion rate of 9α-OH AD is 95.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com