A kind of production method of high-magnesium aluminum alloy sheet

A high-magnesium aluminum alloy and production method technology, applied in the field of aluminum alloy processing, can solve the problems of unstable mechanical properties, uneven thickness control, unstable annealing performance, etc., shorten the production cycle, improve dimensional stability, save Effect of annealing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

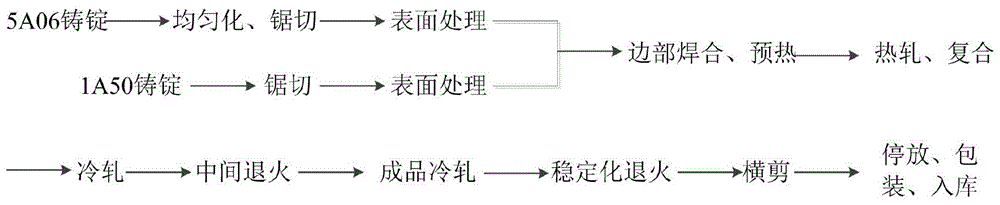

Method used

Image

Examples

Embodiment 1

[0057] Prepare high-magnesium aluminum alloy sheets according to the following steps: (1) Raw material preparation: Weigh aluminum-silicon master alloy, aluminum-iron master alloy, aluminum-copper master alloy, pure magnesium ingot, aluminum Manganese master alloy, aluminum-zinc master alloy, aluminum-beryllium master alloy, aluminum-titanium master alloy and pure aluminum ingot; (2) smelting: the raw materials weighed in step (1) except aluminum-beryllium master alloy and aluminum-titanium master alloy are fed into Smelting in a dome hydraulic inclined melting furnace, the melting temperature is 720°C, and the melting time is 8 hours to obtain an alloy solution; (3) heat preservation: refining, standing still, adding aluminum-beryllium master alloy and aluminum-titanium master alloy, heat preservation temperature 710°C, the holding time is 5h; (4) casting: using semi-continuous casting, the casting temperature is 680°C to obtain alloy ingots; (5) stress relief annealing: place...

Embodiment 2

[0059] Prepare high-magnesium aluminum alloy sheets according to the following steps: (1) Preparation of materials: Weigh aluminum-silicon master alloy, aluminum-iron master alloy, aluminum-copper master alloy, pure magnesium ingot, aluminum Manganese master alloy, aluminum-zinc master alloy, aluminum-beryllium master alloy, aluminum-titanium master alloy and pure aluminum ingot; (2) smelting: the raw materials weighed in step (1) except aluminum-beryllium master alloy and aluminum-titanium master alloy are fed into Smelting in a dome hydraulic inclined melting furnace, the melting temperature is 750°C, and the melting time is 4 hours to obtain an alloy solution; (3) heat preservation: refining, standing still, adding aluminum-beryllium master alloy and aluminum-titanium master alloy, heat preservation temperature 730°C, the holding time is 3h; (4) casting: using semi-continuous casting, the casting temperature is 690°C to obtain alloy ingots; (5) stress relief annealing: place...

Embodiment 3

[0061] Prepare high-magnesium aluminum alloy sheets according to the following steps: (1) Raw materials: Weigh aluminum-silicon master alloy, aluminum-iron master alloy, aluminum-copper master alloy, pure magnesium ingot, aluminum Manganese master alloy, aluminum-zinc master alloy, aluminum-beryllium master alloy, aluminum-titanium master alloy and pure aluminum ingot; (2) smelting: the raw materials weighed in step (1) except aluminum-beryllium master alloy and aluminum-titanium master alloy are fed into Smelting in a dome hydraulic tilting melting furnace with a melting temperature of 740°C and a melting time of 5 hours to obtain an alloy solution; (3) heat preservation: refining, standing still, adding aluminum-beryllium master alloy and aluminum-titanium master alloy, heat preservation temperature 720°C, the holding time is 4h; (4) casting: using semi-continuous casting, the casting temperature is 685°C to obtain alloy ingots; (5) stress relief annealing: place the alloy in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com