Method for preparing P-type lightly-doped silicon carbide thin film epitaxy by controlling hydrogen flow

A silicon carbide, low-doping technology, applied in chemical instruments and methods, gaseous chemical plating, from chemically reactive gases, etc., can solve problems affecting device performance, high bond strength of silicon carbide, lattice damage, etc. The effect of simplifying the preparation process, improving device performance, and complete lattice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

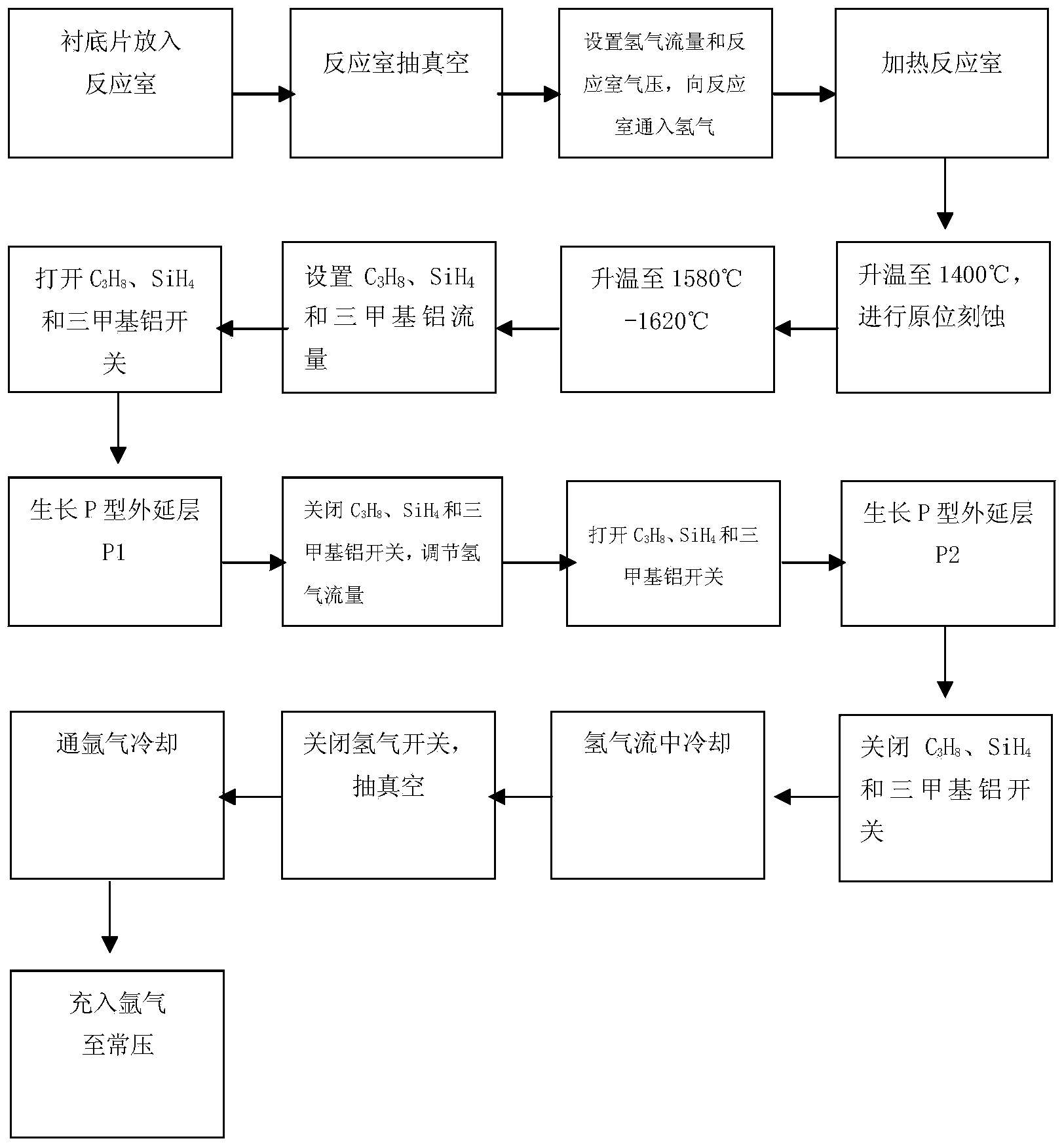

Image

Examples

Embodiment 1

[0020] Step 1, placing the silicon carbide substrate into the reaction chamber of the silicon carbide CVD equipment.

[0021] (1.1) Selection bias A 4H silicon carbide substrate with a crystal orientation of 4° is placed in the reaction chamber of the silicon carbide CVD equipment;

[0022] (1.2) Vacuumize the reaction chamber until the pressure in the reaction chamber is lower than 1×10 -7 mbar.

[0023] Step 2, heating the reaction chamber in the hydrogen flow.

[0024] (2.1) Open the hydrogen switch leading to the reaction chamber, and control the hydrogen flow to gradually increase to 60L / min;

[0025] (2.2) Turn on the vacuum pump to extract the gas in the reaction chamber, and keep the pressure in the reaction chamber at 100mbar;

[0026] (2.3) Gradually increase the power of the heating source to slowly increase the temperature of the reaction chamber.

[0027] Step 3, performing in-situ etching on the substrate.

[0028] (3.1) When the temperature of the reactio...

Embodiment 2

[0042] Step 1, placing the silicon carbide substrate into the reaction chamber of the silicon carbide CVD equipment.

[0043] (1.1) Selection bias A 4H silicon carbide substrate with a crystal orientation of 8° is placed in the reaction chamber of the silicon carbide CVD equipment;

[0044] (1.2) Vacuumize the reaction chamber until the pressure in the reaction chamber is lower than 1×10 -7 mbar.

[0045] Step 2, heating the reaction chamber in the hydrogen flow.

[0046] (2.1) Open the hydrogen switch leading to the reaction chamber, and control the hydrogen flow to gradually increase to 60L / min;

[0047] (2.2) Turn on the vacuum pump to extract the gas in the reaction chamber, and keep the pressure in the reaction chamber at 100mbar;

[0048] (2.3) Gradually increase the power of the heating source to slowly increase the temperature of the reaction chamber.

[0049] Step 3, performing in-situ etching on the substrate.

[0050] (3.1) When the temperature of the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com