Preparation method of high-temperature resistant red fluorescent powder for CCFL (cold cathode fluorescent lamp)

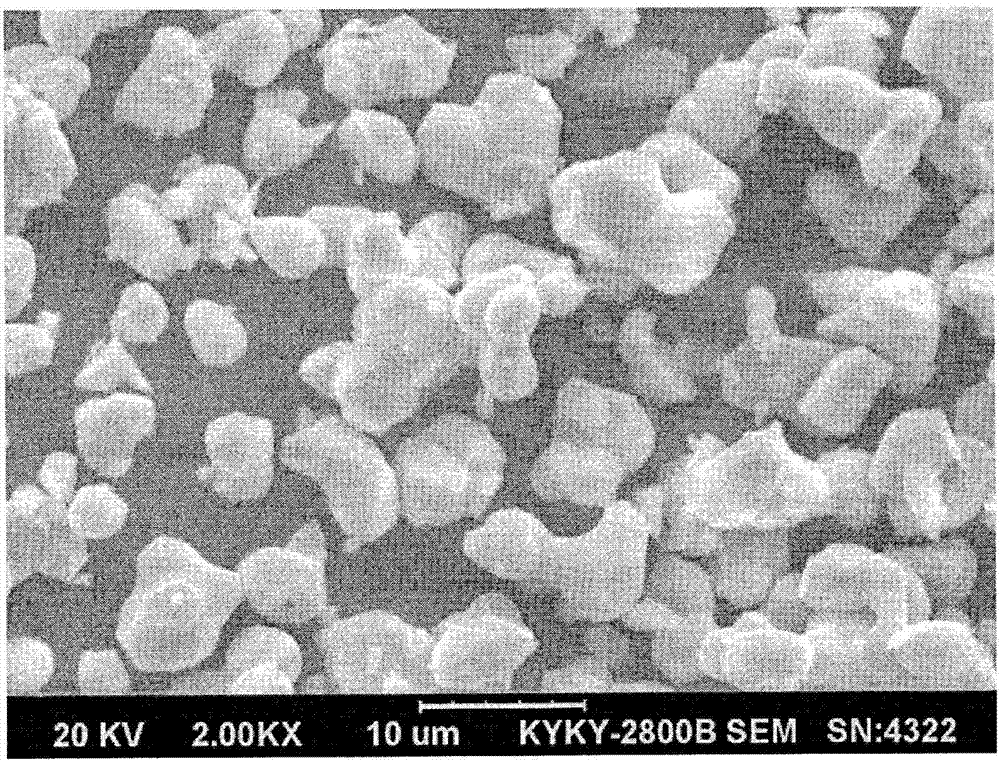

A red phosphor, high temperature-resistant technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of unevenness, insignificant effect, incomplete particle lattice, etc., to achieve complete lattice and excellent surface coating effect. , the effect of uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A) preparing urea solution, dissolving solid urea in deionized water to obtain an aqueous urea solution with a concentration of 15% by mass;

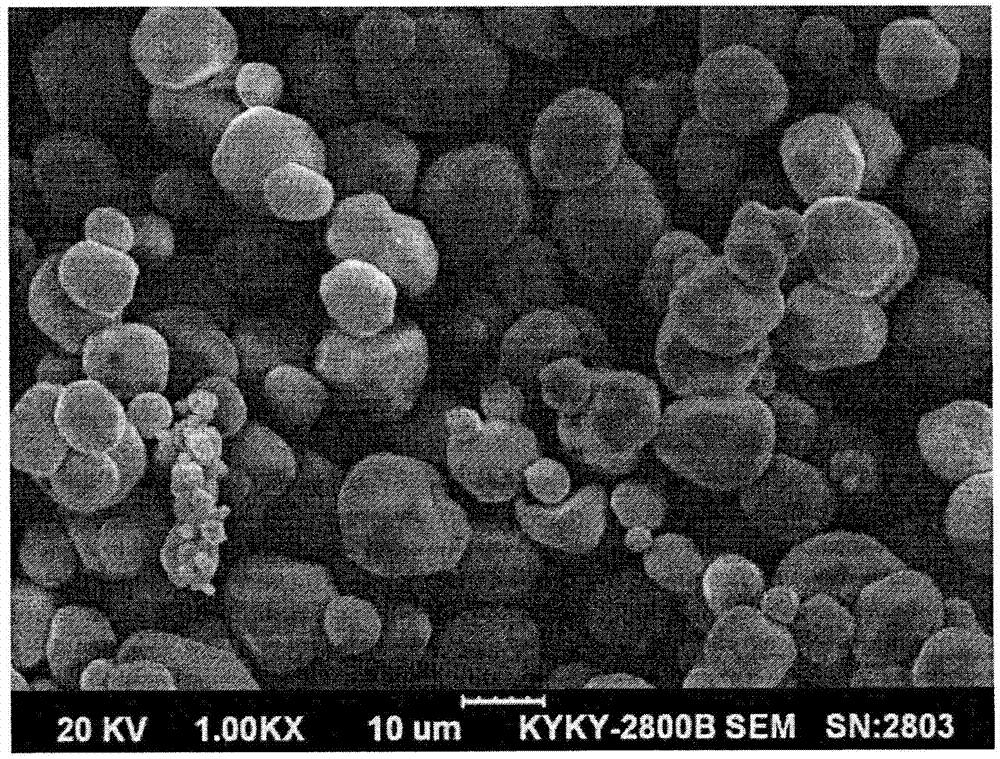

[0031] B) To prepare the first powder, classify the yttrium europium oxide obtained from the commercial channel, that is, the commercial channel, with a grading sieve, that is, obtain the yttrium europium oxide with a particle size of 3.5-4.5 μm by grading the grading sieve, and obtain the first powder body;

[0032] C) Prepare the first slurry, add the first powder obtained in step B into a stirring container filled with deionized water and equipped with a stirrer, and stir, the weight ratio of the first powder to deionized water is 1 : 5, the stirring speed of the agitator is 300n / min, and the stirring time is 180min to obtain the first powder slurry;

[0033] D) To prepare the second slurry, wash the first slurry obtained in step C) with deionized water for 3 times, pass through a 300-mesh sieve after cleaning, and re...

Embodiment 2

[0039] Only change the mass percentage concentration of the urea aqueous solution in step A) to 8%; change the stirring time in step C) to 300min, the stirring speed to 100n / min, and change the weight ratio of the first powder to deionized water Change it to 1: 2; Change the number of times of cleaning in step D) to 5 times, change the sieve after cleaning to 400 mesh sieves; change the weight ratio of the urea aqueous solution in step E) to the second slurry to 1:100, and change the stirring time and speed to 30min and 300n / min respectively; change the standing precipitation time in step F) to 60min; change the drying temperature in step G) to 140°C, and the drying time Change it to 240min, and change the sieve mesh to 90 mesh sieve; change the process parameters of gradient heating and heat preservation in step H) to: first raise the furnace temperature to 1000°C and keep it warm for 180min, then raise the furnace temperature to 1500°C and hold for 180min. All the other a...

Embodiment 3

[0041] Only change the mass percentage concentration of the urea aqueous solution in step A) to 12%; change the stirring time in step C) to 240min, the stirring speed to 200n / min, and change the weight ratio of the first powder to deionized water Change it to 1: 3.5; Change the number of times of cleaning in step D) to 4 times, change the sieve after cleaning to 200 mesh sieves; change the weight ratio of the urea aqueous solution in step E) to the second slurry to 0.75:100, and change the stirring time and speed to 40min and 200n / min respectively; change the standing precipitation time in step F) to 90min; change the drying temperature in step G) to 130°C, and the drying time Change it to 320min, and change the sieve mesh to 110 mesh sieve; change the process parameters of gradient heating and heat preservation in step H) to: first raise the furnace temperature to 1050°C and keep it warm for 150min, then raise the furnace temperature to 1475°C and keep warm for 210min. All...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com