Strippable coating used for metal products, and preparation method of strippable coating

A technology for metal products and coatings, applied in the field of peelable coatings for metal products and their preparation, can solve the problems of heat resistance, low wear resistance, not easy to peel off, etc., and achieves high mechanical strength, good chemical stability, Strong peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

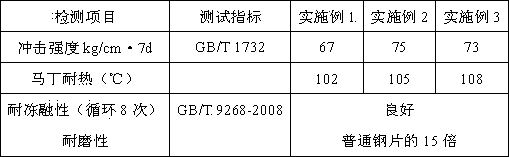

Examples

Embodiment 1

[0011] This embodiment provides a peelable coating for metal products, which contains the following components in parts by mass: 15 parts of neoprene, 3 parts of cellulose acetate butyrate, 0.06 parts of aluminum distearate, and 4 parts of aluminum trioxide , 3 parts of mica powder, 1 part of lithopone, 15 parts of acetone, 52 parts of JSF-6 glue, 3 parts of 10# machine oil, 1 part of phenolic resin, 1 part of anhydrous lanolin, and 70 parts of xylene.

[0012] The preparation steps of a peelable coating for metal products are as follows: firstly, adding neoprene rubber and JSF-6 glue into three-quarter mass parts of xylene, stirring and dissolving, then adding 10# mechanical oil, stirring evenly, and obtaining A; Dissolve the phenolic resin in acetone to obtain B; then dissolve anhydrous lanolin in the remaining xylene to obtain C; then add aluminum distearate to cellulose acetate butyrate, at a temperature of 180 Stir at °C until all dissolved, cool to 40 °C to obtain D; fin...

Embodiment 2

[0014] This embodiment provides a peelable coating for metal products, which contains the following components in parts by mass: 18 parts of neoprene, 4.5 parts of cellulose acetate butyrate, 0.07 parts of aluminum distearate, and 5 parts of aluminum oxide , 5 parts of mica powder, 1.5 parts of lithopone, 18 parts of acetone, 56 parts of JSF-6 glue, 5 parts of 10# machine oil, 1.5 parts of phenolic resin, 1.6 parts of anhydrous lanolin, 76 parts of xylene.

[0015] The preparation steps of a peelable coating for metal products are as follows: firstly, adding neoprene rubber and JSF-6 glue into three-quarter mass parts of xylene, stirring and dissolving, then adding 10# mechanical oil, stirring evenly, and obtaining A; Dissolve the phenolic resin in acetone to obtain B; Dissolve anhydrous lanolin in the remaining xylene to obtain C; Add aluminum distearate to cellulose acetate butyrate, at a temperature of 190 Stir at °C until all dissolved, cool to 50 °C to obtain D; finally, ...

Embodiment 3

[0017] This embodiment provides a peelable coating for metal products, which contains the following components in parts by mass: 22 parts of neoprene, 5.5 parts of cellulose acetate butyrate, 0.08 parts of aluminum distearate, and 7 parts of aluminum trioxide , 6 parts of mica powder, 2 parts of lithopone, 22 parts of acetone, 64 parts of JSF-6 glue, 6 parts of 10# machine oil, 2.2 parts of phenolic resin, 2 parts of anhydrous lanolin, 85 parts of xylene.

[0018] The preparation steps of a peelable coating for metal products are as follows: firstly, adding neoprene rubber and JSF-6 glue into three-quarter mass parts of xylene, stirring and dissolving, then adding 10# mechanical oil, stirring evenly, and obtaining A; Dissolve the phenolic resin in acetone to obtain B; then dissolve the anhydrous lanolin in the remaining xylene to obtain C; then add aluminum distearate to cellulose acetate butyrate, at a temperature of 185 Stir at °C until all dissolved, cool to 45 °C to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com