Solid lipid nanometer particle for astaxanthin and preparation method of solid lipid nanometer particle

A technology of solid lipid nano and astaxanthin, which is applied in the field of medicine, can solve the problems of poor stability and low solubility of astaxanthin, and achieve the advantages of not easy isomerization and degradation, improved absorption rate and bioavailability, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

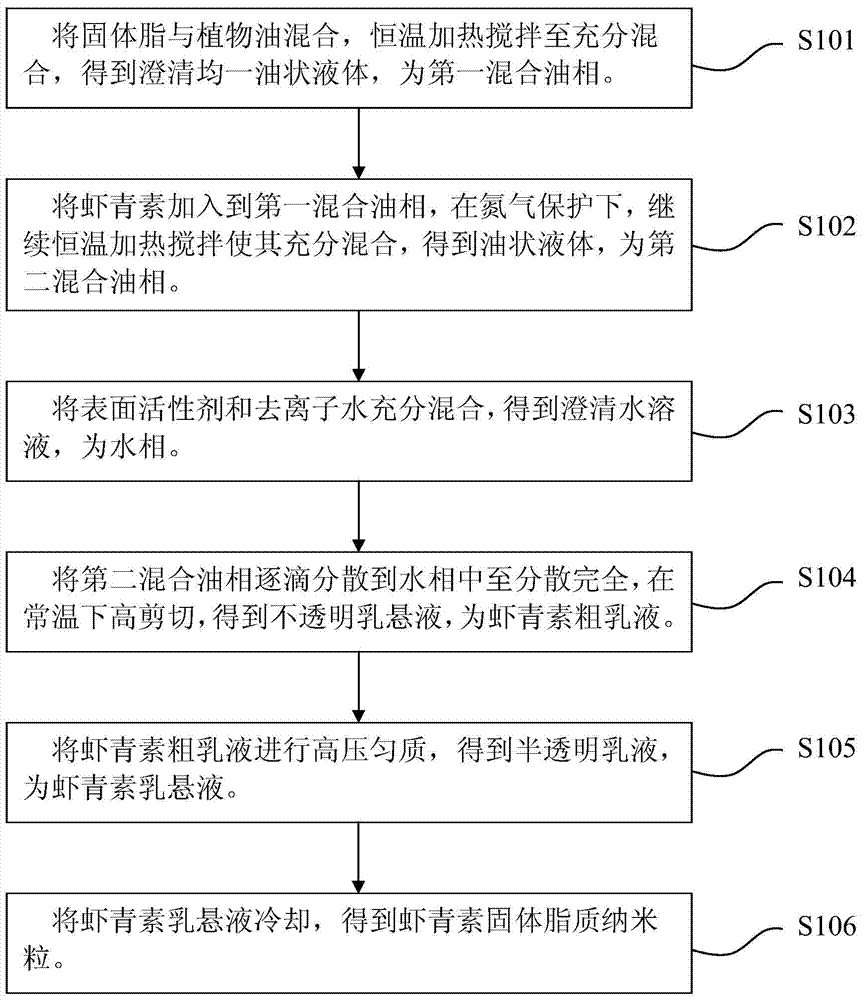

[0033] The embodiment of the present invention also provides a preparation method of astaxanthin solid lipid nanoparticles, comprising:

[0034] Step S101, mixing the solid fat and vegetable oil, heating and stirring at a constant temperature until fully mixed, to obtain a clear and uniform oily liquid, which is the first mixed oil phase;

[0035] Step S102, adding astaxanthin to the first mixed oil phase, and under the protection of nitrogen, continue heating and stirring at a constant temperature to fully mix to obtain an oily liquid, which is the second mixed oil phase;

[0036] Step S103, fully mixing the surfactant and deionized water to obtain a clear aqueous solution, which is the water phase;

[0037] Step S104, dispersing the second mixed oil phase into the water phase drop by drop until the dispersion is complete, and high-shearing at room temperature to obtain an opaque emulsion suspension, which is a coarse emulsion of astaxanthin;

[0038] Step S105, performing h...

Embodiment 1

[0043] Step 1: Accurately weigh 0.05g of stearic acid and 4.95g of soybean oil, place them in a test tube, put the test tube into a water bath magnetic stirrer, set the temperature at 75°C, adjust the speed to 500rpm, and heat for 1 hour to make stearin Dissolve the acid in soybean oil and mix it thoroughly to obtain a milky yellow oily liquid, which is the first mixed oil phase;

[0044] Step 2: Accurately weigh 5 mg of astaxanthin purple crystals (purity>99%), add it to the first mixed oil phase, and at the same time continue to feed nitrogen, continue mixing under the protection of nitrogen, set the temperature to 75 ° C, adjust the speed to 500rpm, heating for 15min, so that astaxanthin is dissolved in stearic acid and soybean oil, and fully mixed with them to obtain a purple oily liquid, which is the second mixed oil phase;

[0045]Step 3: Accurately weigh 5g of surfactant Tween 20 and 50g of deionized water, put them in an 80ml beaker, place the beaker on a magnetic stir...

Embodiment 2

[0058] Step 1: Accurately weigh 0.05g of glyceryl monostearate and 4.95g of soybean oil, place them in a test tube, put the test tube into a water bath magnetic stirrer, set the temperature to 75°C, adjust the speed to 500rpm, and heat for 1h. Glyceryl monostearate is dissolved in soybean oil and fully mixed with it to obtain a milky yellow oily liquid, which is the first mixed oil phase;

[0059] Step 2: Accurately weigh 5 mg of astaxanthin purple crystals (purity>99%), add it to the first mixed oil phase, and at the same time continue to feed nitrogen, continue mixing under the protection of nitrogen, set the temperature to 75 ° C, adjust the speed to 500rpm, heating for 15min, so that astaxanthin is dissolved in glycerol monostearate and soybean oil, and fully mixed with it to obtain a purple oily liquid, which is the second mixed oil phase;

[0060] Step 3: Accurately weigh 5g of surfactant Tween 20 and 50g of deionized water, put them in an 80ml beaker, place the beaker o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com