A kind of ceramic carrying platter for microwave oven and manufacturing method thereof

A technology for microwave ovens and shallow dishes, applied in the field of microwave dielectric ceramics, can solve the problems of poor anti-adhesion, high cost, and impermanence, and achieve the effects of low cost, light weight, and wide selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

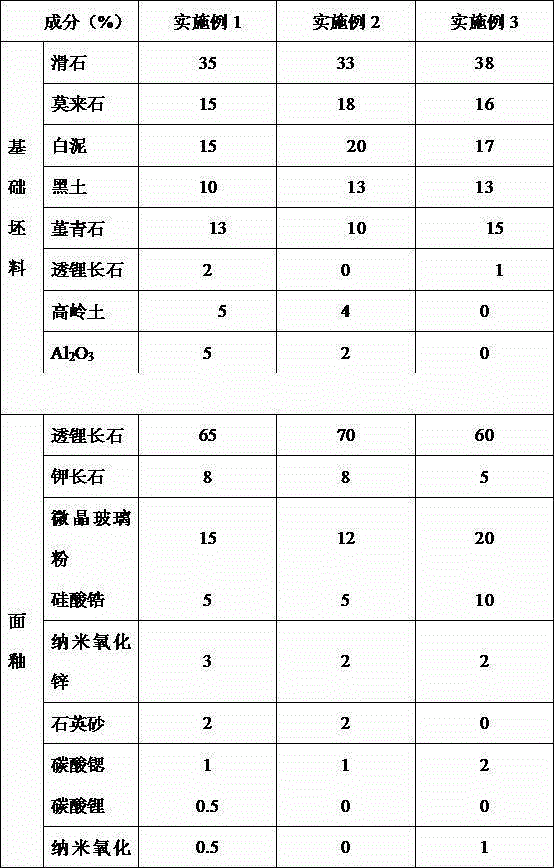

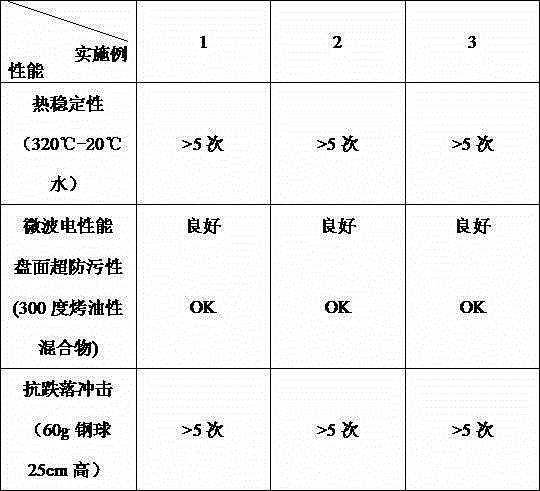

[0013] Below by three specific embodiments the present invention is described in detail as follows:

[0014]

[0015] The weakly frosted glaze on the bottom of the dish contains the following components by weight: petalite 70%, potassium feldspar 10%, barium carbonate 4%, zirconium silicate 4%, spodumene 4%, Suzhou soil 5%, zinc oxide 3%.

[0016] The nano-titanium modified film contains the following components by weight: 90% nano-titanium, 5% high-temperature resin, and 5% low-temperature glass powder.

[0017] The specific production steps and process parameters are as follows:

[0018] The surface and bottom glaze raw materials are divided into balls: material: water = 1.5: 1:0.6 for ball milling and crushing to a certain particle size, and then sieved through iron suction and 300-mesh sieve to obtain the super anti-fouling glaze water on the upper surface and the bottom surface of the plate. Weak frosted glaze glaze water.

[0019] All the green body raw materials a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com