Method for preparing high-strength double-network nano silicon dioxide composite hydrogel

A technology of nano-silica and composite hydrogel, applied in the field of preparation of high-strength double-network nano-composite hydrogel, to achieve the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

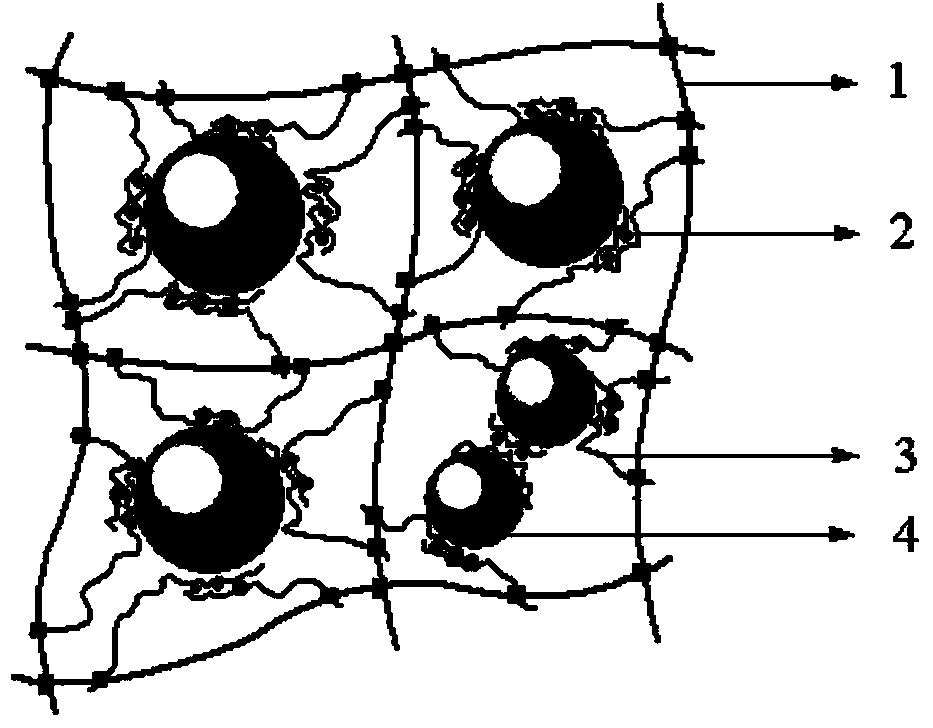

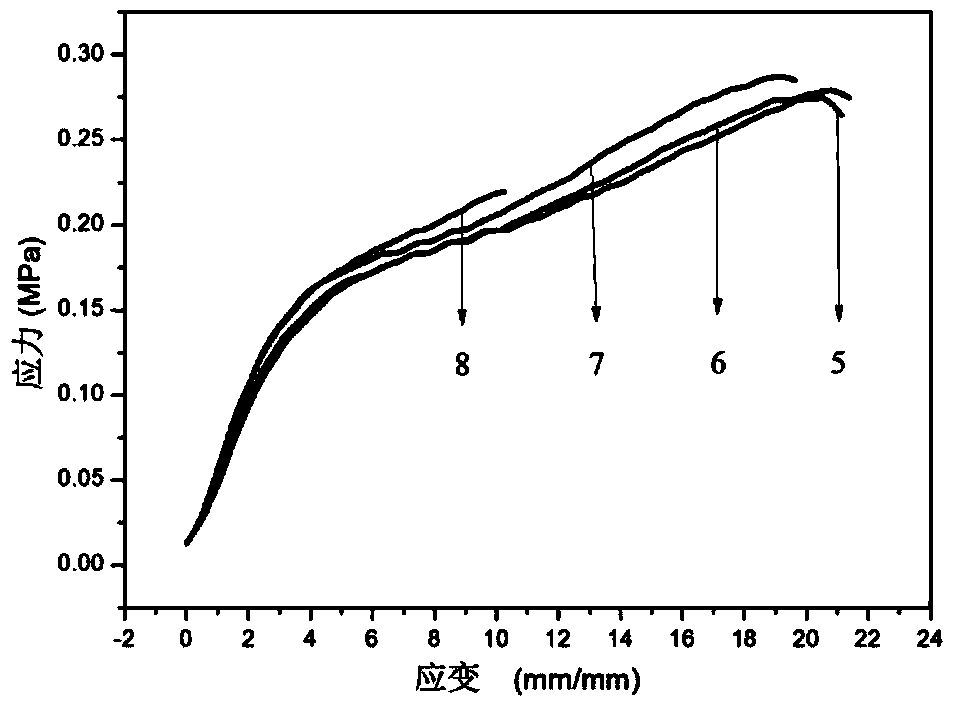

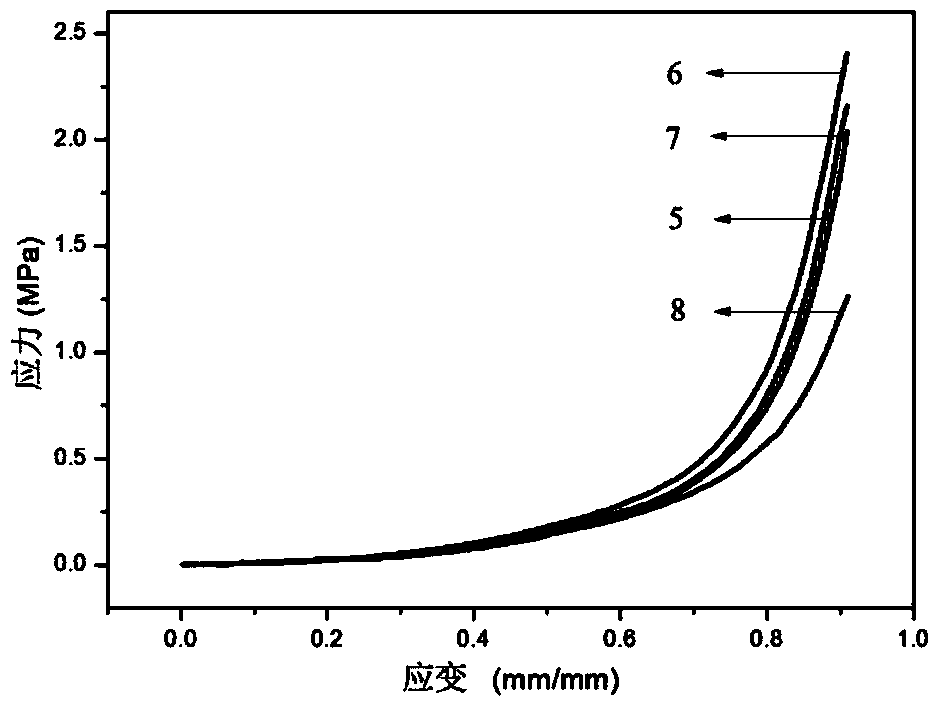

Method used

Image

Examples

Embodiment 1

[0032] 1) Boil distilled water, seal and cool to room temperature to remove oxygen in the water, prepare a mass fraction of 1% nano-SiO with cooled distilled water 2 Aqueous solution, nano-SiO used 2 The particle size is 20-30nm, dispersed evenly by ultrasonic vibration for 10 minutes, and ready for use;

[0033] 2) get sodium alginate and acrylamide to be dissolved in the nano-SiO prepared in step 1) 2 In the aqueous solution, the mass ratio of the sodium alginate to acrylamide is 1:6, and the mass fraction of the total content of sodium alginate and acrylamide is 10%;

[0034] 3) Add N,N'-methylenebisacrylamide, ammonium persulfate, and tetramethylethylenediamine to the solution obtained in step 2), the N,N'-methylenebisacrylamide, persulfate Ammonium sulfate and tetramethylethylenediamine account for 0.03%, 0.1%, and 0.2% of the mass of acrylamide, respectively;

[0035] 4) Transfer the solution prepared in step 3) to a glass mold, seal it, place it at 45°C, and keep it ...

Embodiment 2

[0039] 1) Boil distilled water, seal and cool to room temperature to remove oxygen in the water, and prepare a mass fraction of 10% nano-SiO with cooled distilled water 2 Aqueous solution, nano-SiO used 2 The particle size is 90-100nm, dispersed evenly by ultrasonic vibration for 10 minutes, and ready for use;

[0040] 2) get sodium alginate and acrylamide to be dissolved in the nano-SiO prepared in step 1) 2 In the aqueous solution, the mass ratio of the sodium alginate to acrylamide is 1:6, and the mass fraction of the total content of sodium alginate and acrylamide is 20%;

[0041]3) Add N,N'-methylenebisacrylamide, ammonium persulfate, and tetramethylethylenediamine to the solution obtained in step 2), the N,N'-methylenebisacrylamide, persulfate Ammonium sulfate and tetramethylethylenediamine account for 0.09%, 0.2%, and 0.3% of the mass of acrylamide, respectively;

[0042] 4) Transfer the solution prepared in step 3) to a glass mold, seal it, place it at 55°C, and kee...

Embodiment 3

[0046] 1) The distilled water is boiled and sealed and cooled to room temperature to remove the oxygen in the water, and the mass fraction of 6% nano-SiO is prepared with the cooled distilled water 2 Aqueous solution, nano-SiO used 2 The particle size is 40-50nm, dispersed evenly by ultrasonic vibration for 10 minutes, and ready for use;

[0047] 2) get sodium alginate and acrylamide to be dissolved in the nano-SiO prepared in step 1) 2 In the aqueous solution, the mass ratio of the sodium alginate to acrylamide is 1:6, and the mass fraction of the total content of sodium alginate and acrylamide is 14%;

[0048] 3) Add N,N'-methylenebisacrylamide, ammonium persulfate, and tetramethylethylenediamine to the solution obtained in step 2), the N,N'-methylenebisacrylamide, persulfate Ammonium sulfate and tetramethylethylenediamine account for 0.06%, 0.17%, and 0.25% of the mass of acrylamide, respectively;

[0049] 4) Transfer the solution prepared in step 3) to a glass mold, sea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com