Colored tpu foam material, method and application of using color tpu foam material to prepare shoe material

A technology of foamed materials and foamed sheets, which is applied in the field of colored TPU foamed materials, the preparation of shoe materials by using colored TPU foamed materials, and the application field, which can solve the problem of unstable overall size of foamed materials and increased thermoplastic elastomer hair loss. Foam material density, foam material skin folds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

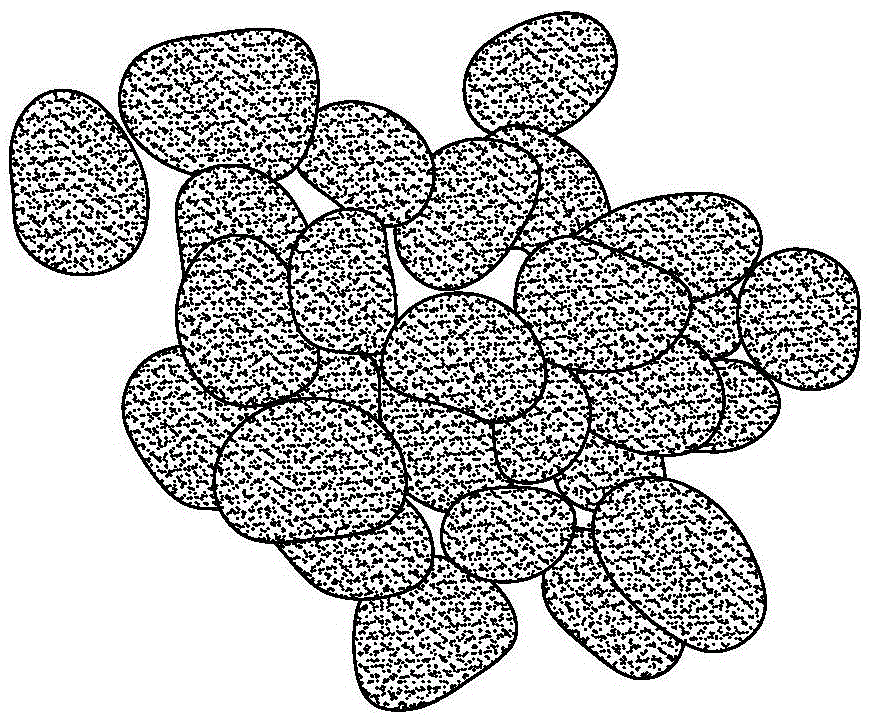

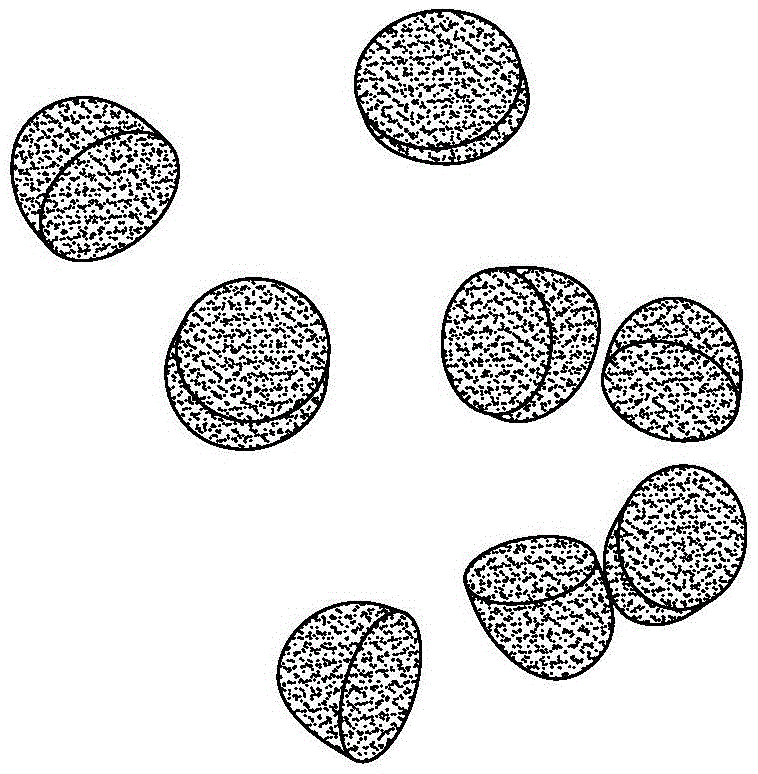

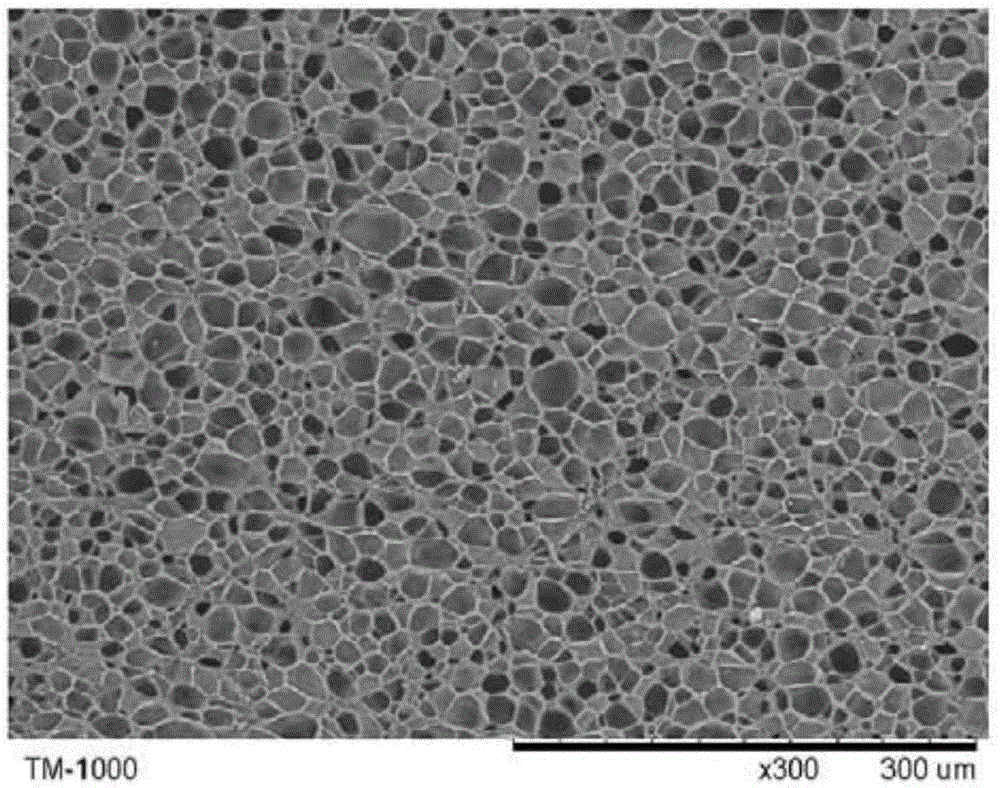

[0091] Dry-mix TPU particles (produced by Ningbo Jinsui Company) with 1wt% yellow organic pigment (Permanent Yellow HR), extrude through an extruder, and granulate under water to make an ellipse with a diameter of 2mm and an aspect ratio of 1.5. Spherical TPU particles. Pellets were placed in an autoclave using low temperature, high pressure CO 2 Fluid impregnated TPU particles to make high pressure CO 2 The fluid reaches a dissolution equilibrium in the TPU resin particles. Put the impregnated TPU particles into a water bath or water vapor for foaming to obtain yellow TPU foamed particles B1. Put the expanded TPU particles B1 into room temperature and high-pressure air under pressure to obtain the expanded TPU particles B2 in yellow color. Table 1 is the relevant process parameters in Example 1. Studies have shown that the obtained yellow TPU expanded particles have a density of 0.18g / cm 3 , the hardness is Shao A15. Such as figure 1 As shown, the obtained yellow TPU e...

Embodiment 2

[0101] Except changing the source of TPU resin (purchased from Ningbo Jinsui, Yantai Wanhua, American Dow Chemical Company, German Bayer Company), granulation size and operating process conditions, other operations are the same as in Example 1. The obtained TPU expanded particle materials are all yellow TPU expanded particle materials with smooth surface and no obvious shrinkage. The incision foamed particles can observe the uniform pigment distribution inside and outside the colored TPU foamed particles. See Table 1 for specific data.

Embodiment 3

[0103] Except that the content of the yellow organic pigment was changed to 0.1, 0.5, 1, 2, 5 wt%, other operations were the same as in Example 1. The obtained TPU foamed materials are all yellow TPU foamed particle materials with smooth surface and no obvious shrinkage. The incision foamed particles can observe the uniform pigment distribution inside and outside the colored TPU foamed particles. See Table 2 for specific data.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com