Low-temperature destructive distillation pyrolysis method of lignite

A low-temperature, lignite technology, applied in the field of dry distillation and pyrolysis of coal, can solve the problems of low utilization rate of lignite resources and high pollutant discharge, and achieve the effects of avoiding waste, reducing environmental pollution and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

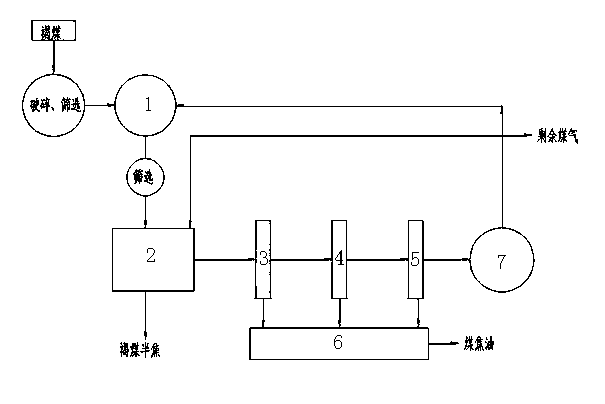

[0029] In order to overcome the problems of low resource utilization rate of lignite and high pollutant discharge in the prior art, this embodiment provides a method such as figure 1 and figure 2 The shown lignite low-temperature dry distillation pyrolysis method comprises the following steps:

[0030] 1) crushing and screening the lignite transported from the coal mine, and selecting the undersize whose particle size is below 150 mm;

[0031] 2) Send the undersize into the vertical drying furnace 1 and directly dry it with low-temperature flue gas below 250 degrees, contact it in reverse with the lignite, and dry the undersize in the vertical drying furnace for 3 hours to remove part of the moisture;

[0032] 3) Concentrating the undersize from which part of the moisture has been removed into the discharge hopper at the bottom of the vertical drying furnace 1, and then sieving it, and selecting the undersize with a particle size of 30 to 150 mm as the low-temperature dry di...

Embodiment 2

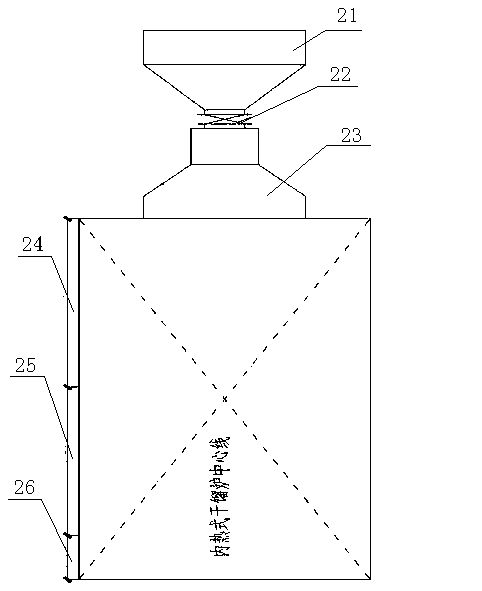

[0042]On the basis of Example 1, the undersieve in the step 2) is sent into the upper hopper of the vertical drying furnace 1 by a belt conveyor, and is distributed in the vertical drying furnace 1 through a distributor and baked by a flow interceptor , diversion exhaust steam turning over material; said step 2) in the process of natural settlement from top to bottom of the vertical drying furnace 1, the under-sieve sinks through the curve of the multi-stage tower component, and the material is in the vertical drying furnace. The drying furnace 1 is continuously and slowly turned and turned back, and the heated contact surface is changed, and finally the moisture content of the undersize material that has removed part of the moisture in the vertical drying furnace 1 is ≤ 20%.

[0043] In the step 2), the heat required for the dehydration of the undersize material is supplied by the hot blast stove arranged at the bottom of the vertical drying furnace 1, and the hot air flow is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com