Preparation method of sea cucumber polypeptide

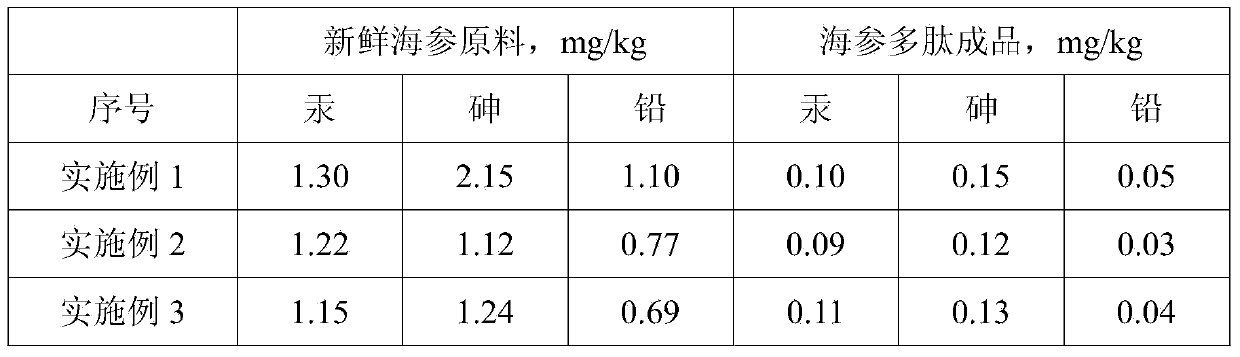

A technology of sea cucumber polypeptides and sea cucumbers, which is applied in the field of preparation of sea cucumber polypeptides, which can solve the problems of excessive heavy metal content, large molecular weight, and difficulty in absorption, and achieve the effects of low wastewater discharge, mild reaction conditions, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

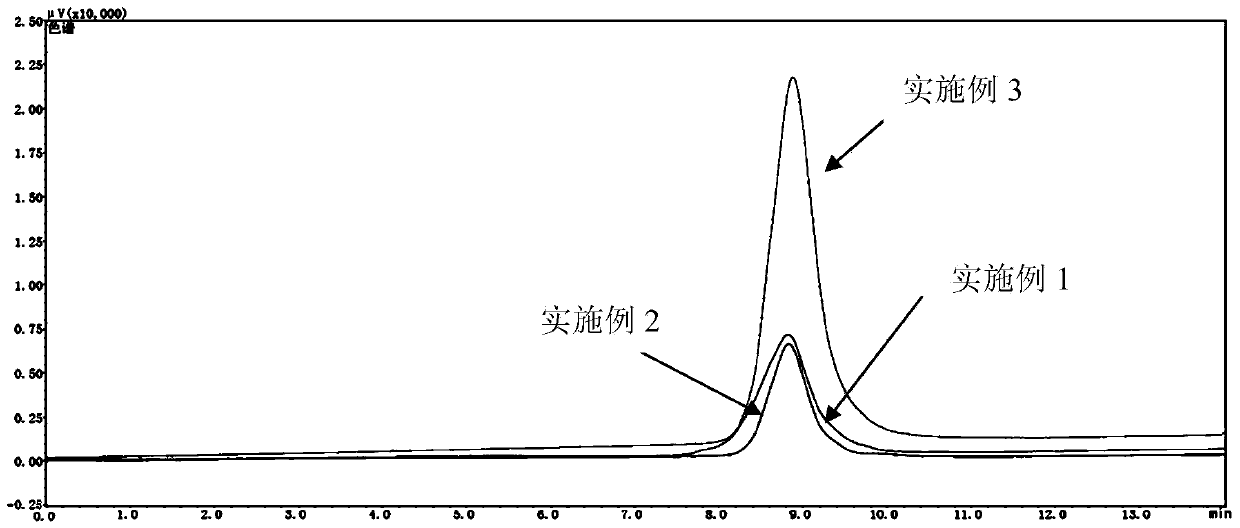

Embodiment 1

[0019] Example 1: Select fresh Liao sea cucumber as sea cucumber raw material to prepare sea cucumber polypeptide:

[0020] 1) Screening of raw materials: Screening and preparing some fresh sea cucumbers;

[0021] 2) Cleaning of raw materials: Wash the screened japonicus japonicus with tap water first, and then clean it with ultrapure water with a conductivity of 10 Us / cm, so as to wash away the silt in the japonicus japonicus japonicus;

[0022] 3) Low-temperature enzymatic hydrolysis: Put ultrapure water with a conductivity of 5 Us / cm equal to the weight of sea cucumber in the biological enzymatic hydrolysis tank, and heat it to 60°C; then put it in the biological enzymatic hydrolysis tank to wash Apostichopus japonicus, heated to 50°C; put in 0.5% papain by weight of Apostichopus japonicus, and enzymolyze it at 50°C for 3 hours; Enzymolysis treatment for 15 hours; put in activated carbon with 0.5% weight of sea cucumber, and place for 1 hour; put in quartz sand with 1% wei...

Embodiment 2

[0027] Example 2: Select fresh sea cucumber as sea cucumber raw material to prepare sea cucumber polypeptide:

[0028] 1) Raw material screening: screening and preparing some fresh sea cucumbers;

[0029] 2) Cleaning of raw materials: Wash the screened sea cucumber with tap water first, and then clean it with ultra-pure water with a conductivity of 15 Us / cm, so as to wash away the sediment in the sea cucumber body;

[0030] 3) Low-temperature enzymatic hydrolysis: put ultrapure water with a conductivity of 2 Us / cm equal to that of sea cucumber in the biological enzymatic hydrolysis tank, and heat it to 55°C; then put it in the biological enzymatic hydrolysis tank and wash of sea cucumber, heated to 48°C; put in 0.6% papain by weight of sea cucumber, and enzymatically treat it at 48°C for 2.5h; put in collagenase of 0.6% by weight of sea cucumber, Enzyme hydrolysis treatment for 18 hours; put 0.5% of the weight of sea cucumber in activated carbon, and let it stand for 1.5 hour...

Embodiment 3

[0035] Example 3: Select fresh plum blossom as the sea cucumber raw material to prepare sea cucumber polypeptides:

[0036] 1) Raw material screening: screening and preparing some fresh plum blossom ginseng;

[0037] 2) Cleaning of raw materials: Wash the screened plum blossom ginseng with tap water first, and then wash it with ultrapure water with a conductivity of 5 Us / cm to clean the sediment in the plum blossom ginseng body;

[0038]3) Low-temperature enzymatic hydrolysis: put ultrapure water with a conductivity of 0.1 Us / cm equal to the weight of plum flower ginseng in the biological enzymatic hydrolysis tank, and heat it to 60°C; then put it into the biological enzymatic hydrolysis tank to wash Plum blossom ginseng, heated to 52°C; put in 0.4% by weight of plum blossom ginseng with papain, and enzymolyze at 52°C for 4 hours; put in 0.5% by weight of plum blossom ginseng, and enzymolyze at 52°C 18h; put in activated carbon with 0.5% weight of plum blossom ginseng and let...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com