A method for preparing solar cell absorbing layer material CZTS/CZTSSE by water bath lamination

A technology for solar cells and absorbing layers, applied in the direction of sustainable manufacturing/processing, circuits, photovoltaic power generation, etc., can solve problems such as hard to obtain, long-term cycle, etc., achieve simple preparation process, simple and uncomplicated preparation equipment, and low preparation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

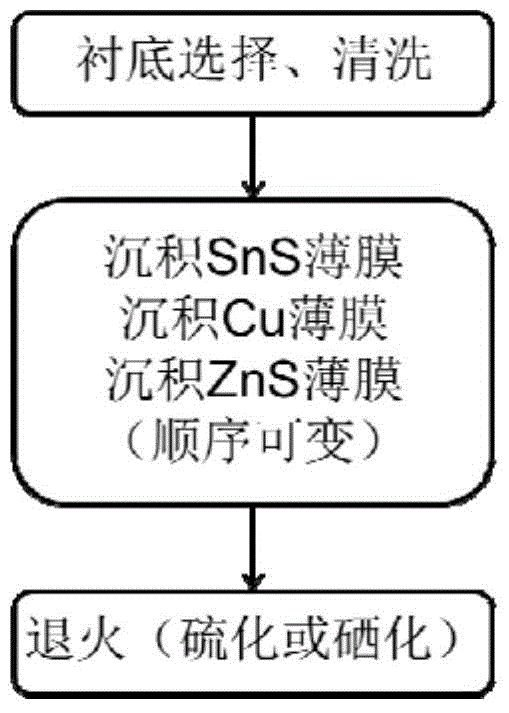

Method used

Image

Examples

Embodiment 1

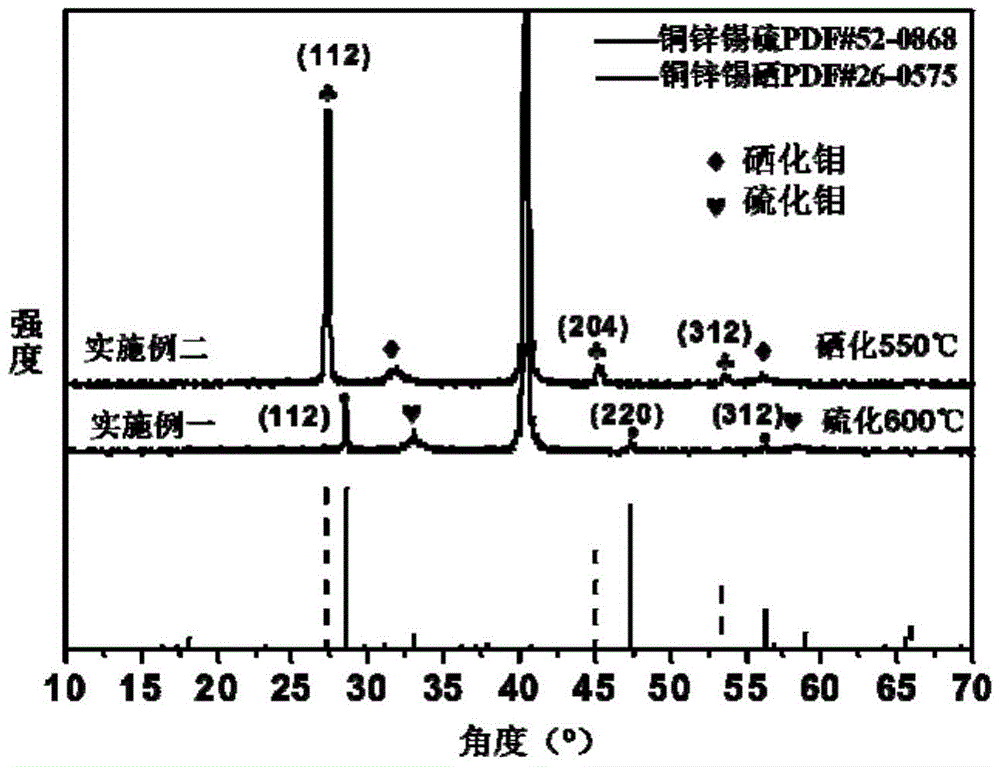

[0050] Embodiment 1: Preparation based on CZTS film

[0051] 1) Clean the molybdenum-coated glass substrate first: immerse the substrate in ethanol and ammonia solution in sequence, then deionized water and ultrasonically rinse it, and dry it with nitrogen.

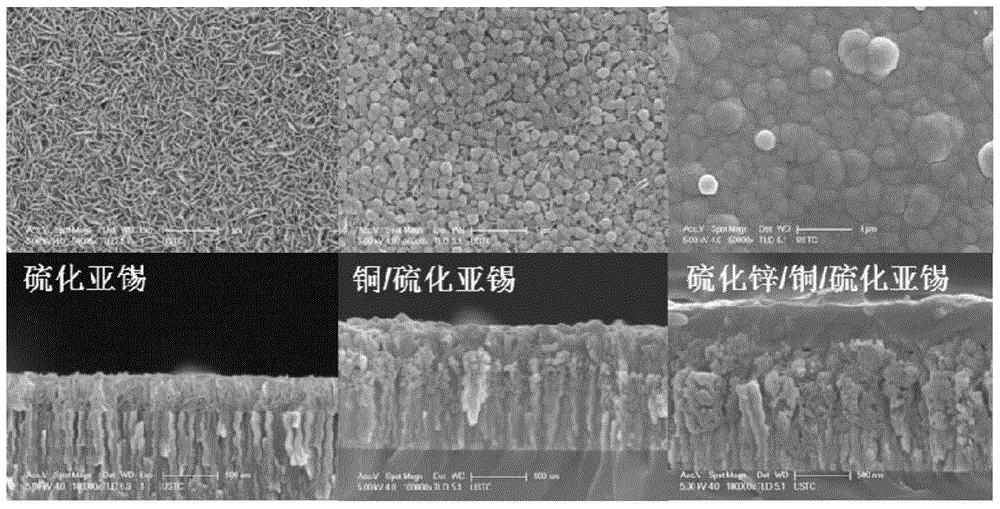

[0052] 2) On the surface of the clean molybdenum substrate obtained in step 1), a layer of SnS film is deposited in a chemical water bath; the molybdenum substrate is vertically placed in a 30ml vial, and the deposition solution is configured; 1g of analytically pure tin protochloride (SnCl 2 2H 2 O) add 5ml absolute ethanol to dissolve, then add 3ml28% ammoniacal liquor, add 12ml50% triethanolamine after 30s as complexing agent and the 1M thioacetamide of 8ml (C 2 h 5 NS) as a sulfur source, the concentration of tin protochloride in the deposition solution is 0.044M, the volume fraction of triethanolamine is 6%, the concentration of thioacetamide is 0.08M, and the pH is adjusted to 13 by alkaline solution, and finally ...

Embodiment 2

[0056] Example 2: Based on the preparation of CZTSSe thin film, the preparation of the precursor film is consistent with that of Example 1

[0057] 1) Clean the molybdenum-coated glass substrate first: immerse the substrate in ethanol and ammonia solution in sequence, then deionized water and ultrasonically rinse it, and dry it with nitrogen.

[0058] 2) On the surface of the clean molybdenum substrate obtained in step 1), a layer of SnS film is deposited in a chemical water bath; the molybdenum substrate is vertically placed in a 30ml vial, and the deposition solution is configured; 1g of analytically pure tin protochloride (SnCl 2 2H 2 O) add 5ml absolute ethanol to dissolve, then add 3ml28% ammoniacal liquor, add 12ml50% triethanolamine after 30s as complexing agent and the 1M thioacetamide of 8ml (C 2 h 5 NS) as a sulfur source, the concentration of tin protochloride in the deposition solution is 0.044M, the volume fraction of triethanolamine is 6%, the concentration of ...

Embodiment 3

[0062] Embodiment 3: the embodiment carried out based on the soda silicate glass substrate in the optional substrate

[0063] 1) Clean the soda-silicate glass substrate first: immerse the substrate in ethanol and deionized water in sequence for ultrasonication for 10 minutes respectively, rinse with deionized water, and blow dry with nitrogen.

[0064] 2) Deposit a layer of SnS film in a chemical water bath on the surface of the clean soda-silicate glass obtained in step 1); the soda-silicate glass substrate is vertically placed in a 30ml vial, and the deposition solution is configured; 1g of analytically pure stannous chloride (SnCl 2 2H 2 O) add 5ml absolute ethanol to dissolve, then add 3ml28% ammoniacal liquor, add 12ml50% triethanolamine after 30s as complexing agent and the 1M thioacetamide of 8ml (C 2 h 5 NS) as a sulfur source, the concentration of tin protochloride in the deposition solution is 0.044M, the volume fraction of triethanolamine is 6%, the concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com