A kind of lithium ion battery negative plate and preparation method thereof, lithium ion battery

A technology of lithium ion battery and negative electrode sheet, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve problems such as cumbersome process, achieve simple process, ensure electron transmission capacity, save conductive agent and The effect of the use of the binder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

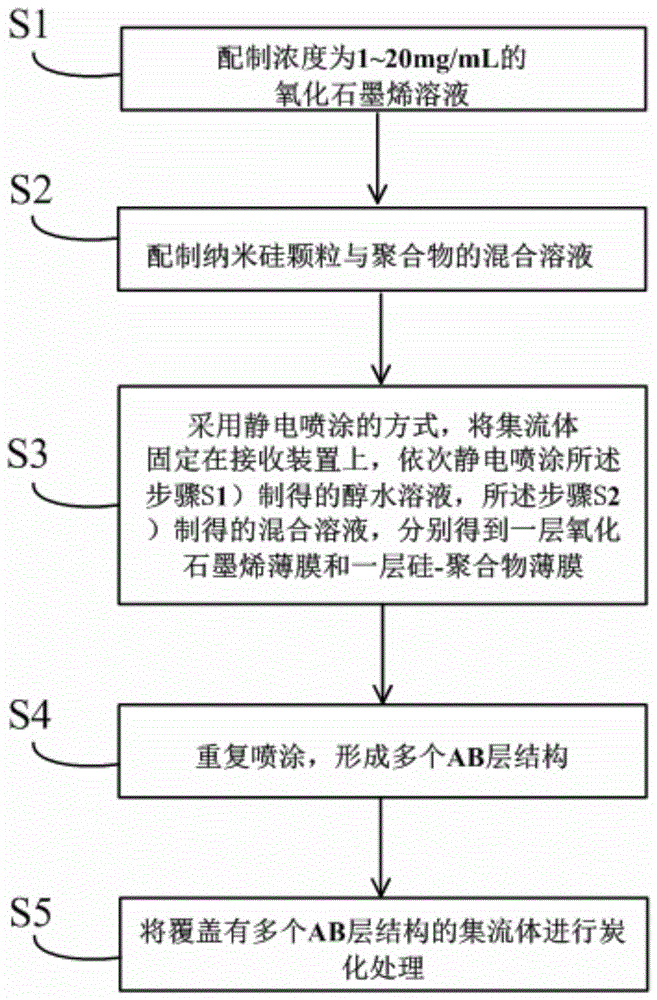

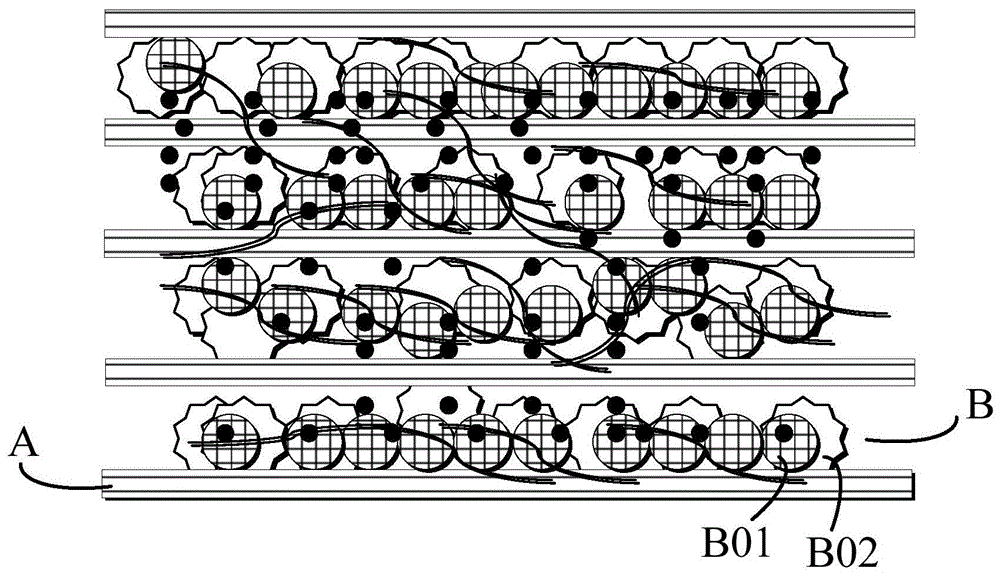

[0015] Such as figure 1 Shown is the flow chart of the preparation method of the lithium-ion battery negative plate of the specific embodiment, and the preparation process includes the following steps:

[0016] S1) Prepare a graphene oxide solution with a concentration of 1-20 mg / mL.

[0017] Specifically, the improved Hummer's method can be used to prepare graphite oxide, and then accurately weigh a certain mass of graphite oxide, dissolve it in deionized water of a certain mass, and perform ultrasonic dispersion treatment to obtain a homogeneous aqueous solution of graphene oxide with a certain mass fraction, and then Mix it with absolute ethanol at a volume ratio of 1:1 to finally obtain a homogeneous solution of graphene oxide with a concentration of 1-20 mg / mL, which is designated as solution M.

[0018] S2) Prepare a mixed solution of nano-silicon particles and polymers; dissolve the nano-silicon particles and polymers in an aqueous alcohol solution to prepare the mixed...

experiment example 1

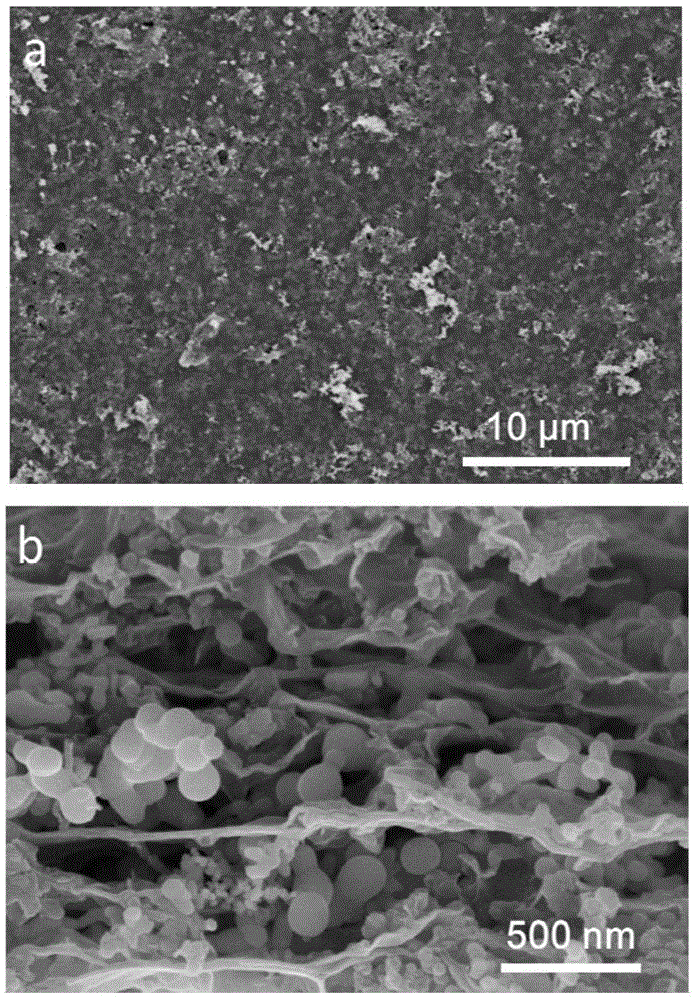

[0034] The first step: the preparation of a homogeneous solution of graphene oxide. Graphite oxide was prepared by modified Hummer's method. Accurately weigh 160 mg of graphene oxide, dissolve it in 80 mL of deionized water, and ultrasonically obtain a 2 mg / mL graphene oxide homogeneous solution, then mix it with absolute ethanol at a volume ratio of 1:1 to obtain a 1 mg / mL graphene oxide homogeneous solution. mL of a homogeneous solution of graphene oxide, denoted as solution M.

[0035] The second step: the preparation of the mixed solution of nano-silicon particles and polymer. Accurately weigh 40mg of nano-silicon particles (nano-silicon particles with a diameter of 30-100nm are used in this experimental example), dissolve 200mg of PVP in 20mL of alcohol aqueous solution, stir thoroughly for 4 hours, and sonicate for 1 hour to obtain a mixture of nano-silicon particles and polymers. The mixed solution is denoted as solution N1. That is, in the N1 solution, the concentra...

experiment example 2

[0044] Experimental Example 2: Compared with Experimental Example 1, the only difference between this experimental example is that in the third and fourth steps, the flow rate and spraying time of the spray are controlled so that the mass ratio of the final film A to film B1 is 1:7.5 . Finally, the maximum reversible specific capacity of the prepared negative electrode sheet was 1580mAh / g, the charging specific capacity (delithiation) after 100 cycles was 910mAh / g, and the capacity retention rate was 57.6%.

[0045] From the comparison of Experimental Example 1 and Experimental Example 2, it can be seen that when the mass ratio of film A to film B1 is adjusted, the capacity performance of the final negative electrode sheet is similar. The possible reason is that although the ratio of the coating mass of the film has changed, the mass fraction of the silicon material in the active material layer is almost the same (between 55-60%) due to the small amount remaining after the car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com