Adsorbent for purifying coal ethylene glycol and preparation method of adsorbent for purifying coal ethylene glycol

An adsorbent and ethylene glycol technology, applied in the field of purifying coal-based ethylene glycol quality adsorbent and its preparation, can solve problems such as low efficiency and achieve the effect of improving quality and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation process of the adsorbent is the modification method of the adsorbent. The modified activated carbon adds metal ions, and these ions have a certain adsorption effect on trace impurities (mainly polar substances) in coal-based ethylene glycol, so that the relatively weak polar UV light-absorbing impurities in the ethylene glycol system are in the liquid It is in a favorable position in the competitive adsorption, so that the selectivity and adsorption capacity of the adsorbent can be greatly improved.

[0017] The purification effect of ethylene glycol is not only related to the physical and chemical properties of the adsorbent itself, but also the liquid phase space velocity and refining temperature are also closely related to the adsorption capacity of the adsorbent. Studies have shown that the refining temperature is 20-50 ° C, and the liquid phase space velocity is 1.5 hr -1 When the effect is obvious, other reaction conditions are less effective.

Embodiment

[0019] Preparation of adsorbent: Dissolve 100g of modified chitosan monomer in 1000g of water, stir at 80°C for 2h, then add 17.28g of ferric nitrate, 5.86g of copper nitrate, and 31.29g of ammonium phosphate, and stir evenly in a water bath at 100°C. And form a gel, dry in a vacuum oven at 150°C for 10h, and finally calcinate in a muffle furnace at 600°C for 2h to obtain the finished 2FelCu / C adsorbent.

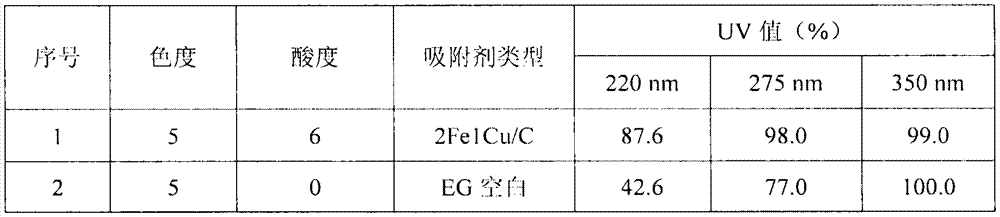

[0020] Put the adsorbent sample into the adsorption bed. The adsorption bed is composed of 4 stainless steel tubes with a length of 50 cm and an inner diameter of 5. The bottom is equipped with a 200-mesh nylon mesh to prevent the fine powder from flowing out with ethylene glycol. The stainless steel tube is half filled with the adsorbent. Under the above conditions, control the refining temperature at 20-50°C, and the liquid phase space velocity at 2.5hr -1 After passing through the bed, test the light transmittance, acidity and chromaticity experiments before and after pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com