Method for preparing protein feed from straw and inedible vegetables through mixed bacteria aerobic fermentation

A technology of aerobic fermentation and protein feed, applied in biochemical equipment and methods, animal feed, animal feed, etc., can solve the problems of long production cycle of anaerobic fermentation feed, slow growth and reproduction of bacterial cells, loss of nutrient elements of tail vegetables, etc. , to achieve the effect of enhancing the body's immunity and disease resistance, eliminating toxins and their metabolites, and enhancing reproduction and growth vigor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

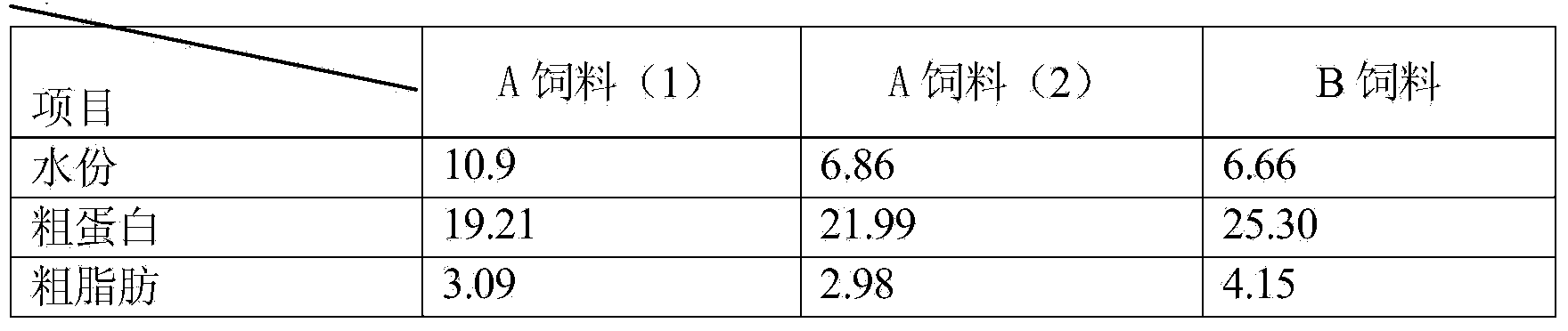

Embodiment 1

[0037] Example 1: After 0.5% H 2 SO 4 Treated corncob flour, cabbage tailings, rapeseed meal, and bran, wherein the weight ratio of corncob flour: cabbage tailings: rapeseed meal: bran is 1:3:2:0.5, and added relative to the total amount of dry matter Ammonium sulfate is 4%, urea is 3%, after fully mixing, adjust the water content of the solid fermentation material to 50%, adjust the pH value to 5.5 with 1% lime water, and then add Geotrichum candidum which is 12% relative to the total amount of dry material , lactic acid bacteria, aspergillus niger mixed bacteria solution, the weight ratio of Geotrichum candidum, lactic acid bacteria, Aspergillus niger is 65% of Geotrichum candidum, 25% of lactic acid bacteria, 10% of Aspergillus niger. After fully stirring and mixing evenly, stack it until the temperature reaches 32°C, spread it on the ground with a thickness of 10cm, and ferment and cultivate it at a room temperature of 32°C for 24 hours. The crude protein of the product c...

Embodiment 2

[0038] Example 2: After 1% H 2 SO 4 Processed wheat straw powder, lotus cauliflower, rapeseed meal, and bran, wherein the weight ratio of wheat straw powder: lotus cauliflower: rapeseed meal: bran is 1:3:3:1, and added relative to the total amount of dry matter Ammonium sulfate is 2%, urea is 1%, and the water content of the solid fermentation material is adjusted to 55%. After mixing well, adjust the pH value to 6.5 with 1% lime water, and then add Geotrichum candidum which is 8% relative to the total dry material , lactic acid bacteria, aspergillus niger mixed bacteria solution, the weight ratio of Geotrichum candidum, lactic acid bacteria, Aspergillus niger is 70% of Geotrichum candidum, 25% of lactic acid bacteria, 5% of Aspergillus niger. After fully stirring and mixing evenly, stack it until the temperature reaches 30°C, spread it on the ground with a thickness of 10cm, and ferment and cultivate it at a room temperature of 30°C for 24 hours. The crude protein of the pro...

Embodiment 3

[0039] Example 3: After 1.5% H 2 SO 4 The processed corn stalk powder is steamed and processed, and celery tails, rapeseed meal and bran are added, wherein the weight ratio of corn stalk powder: celery tails: rapeseed meal: bran is 2:4:3:1, and the relative Ammonium sulfate is 4% and urea is 3% in the total amount of dry material, and the moisture content of the solid fermentation material is adjusted to 55%, and the pH is adjusted to 5.5 with 1% lime water, and then 9% of Geotrichum candidum, The bacterial liquid mixed with lactic acid bacteria and Aspergillus niger, the weight ratio of Geotrichum candidum, lactic acid bacteria and Aspergillus niger is 65% of Geotrichum candidum, 20% of lactic acid bacteria, and 15% of Aspergillus niger. After fully stirring and mixing evenly, stack until the temperature rises to 35°C When it is laid on the ground with a thickness of 10cm, it is fermented and cultivated at a room temperature of 32°C for 20 hours, and the crude protein of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com