A method for separating mixed gas by hydrate method

A technology for mixing gas and hydrate solids, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., and can solve the problems of low energy consumption for separation, high energy consumption for gas hydrate separation, and difficulty in heat transfer and flow in large-scale installations. problems, to achieve the effect of large separation capacity, avoid poor contact heat transfer effect, and save energy consumption for transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

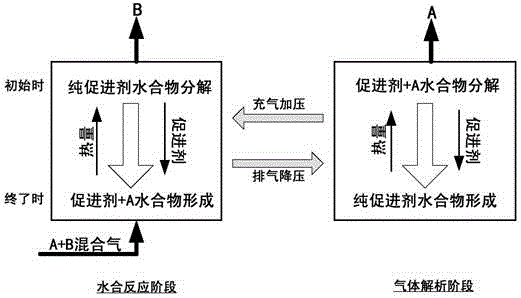

[0037] Example 1: The hydrate method for separating mixed gases, the principle of internal heat and mass coupling technology in the separation process

[0038] like figure 1 As shown, taking A+B mixed gas as an example to illustrate the phase change of hydrates in the separation process of the present invention and the coupling of hydrate formation, decomposition heat, and accelerator concentration, A is the component that is easy to form hydrates, and B is difficult to form hydrates components of things. When the hydrate reaction stage begins, the reactor is a solid-liquid mixed slurry composed of pure accelerator hydrate solid and aqueous solution containing the accelerator, and the ratio of the accelerator dose entering the pure accelerator hydrate solid to the accelerator dose dissolved in the slurry can be It is determined by controlling the solid concentration of the pure accelerator hydrate generated in the solution; when the A+B mixed gas is injected into the reactor ...

Embodiment 2

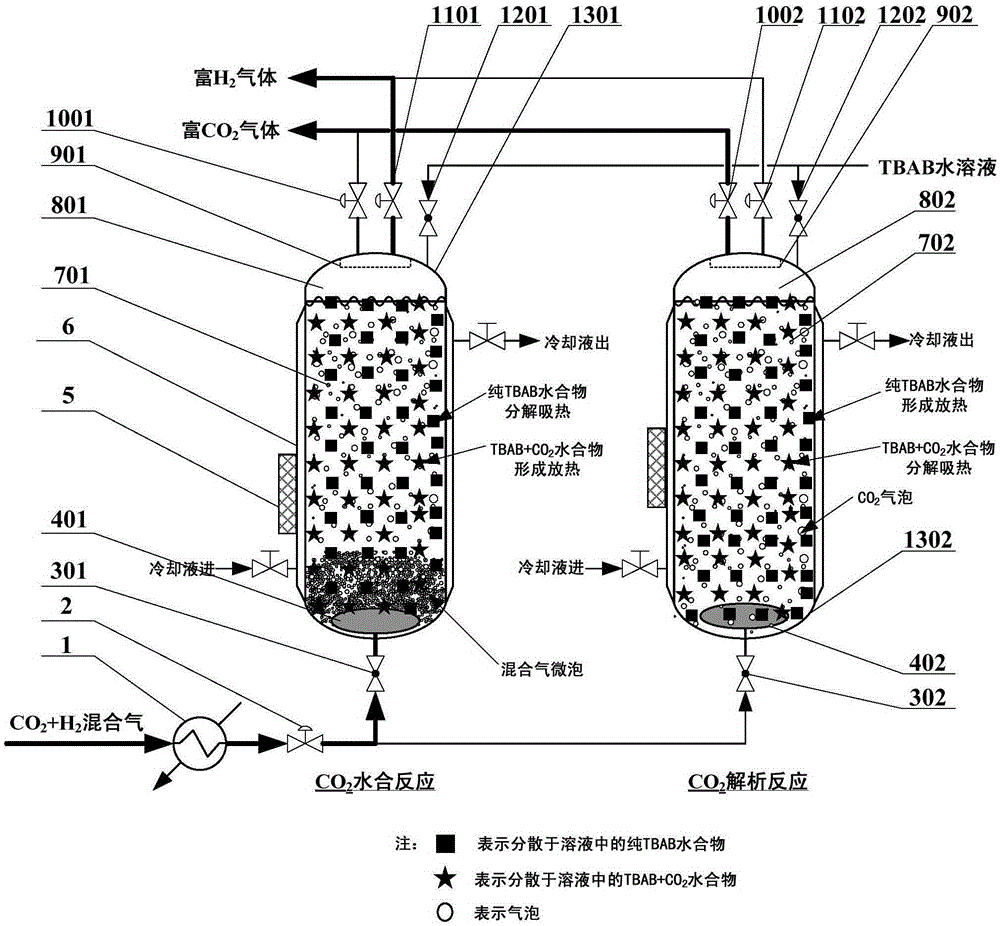

[0039] Embodiment 2: Separation of raw gas CO 2 +H 2

[0040] like figure 2 As shown, the system for separating mixed gases consists of two identical reactors 1301 and 1302 connected in parallel. During normal operation, one is used as a hydration reactor and the other is used as a gas analyzer, and the two are switched to ensure that Continuity of separation process. Feed gas is CO 2 +H 2 Mixed gas (mole percentage is 40mol% CO 2 and 60mol% H 2 ), the accelerator aqueous solution that adopts is the tetrabutylammonium bromide (TBAB) aqueous solution that mass percentage content is 21.5wt%. Before the separation begins, inject a certain amount of 21.5wt% TBAB solution into reactors 1301 and 1302 respectively by shut-off valves 1201 and 1202, open the cooling water inlet and outlet valves of reactor cooling jacket 6, and cool the TBAB solution in the reactor. To below 280.5K, pure TBAB hydrate solids are generated, and the mass concentration of TBAB hydrate solids in th...

Embodiment 3

[0044] Embodiment 3: Separation of raw gas CO 2 +H 2

[0045] like figure 2 As shown, the system for separating mixed gases consists of two identical reactors 1301 and 1302 connected in parallel. During normal operation, one is used as a hydration reactor and the other is used as a gas analyzer, and the two are switched to ensure that Continuity of separation process. Feed gas is CO 2 +H 2 Mixed gas (mole percentage is 40mol%CO 2 and 60mol% H 2 ), the accelerator aqueous solution that adopts is the tetrabutylammonium bromide (TBAB) aqueous solution that mass percentage content is 20wt%. Before the separation begins, inject a certain amount of 20wt% TBAB solution into reactors 1301 and 1302 respectively by shut-off valves 1201 and 1202, open the cooling water inlet and outlet valves of reactor cooling jacket 6, and cool the TBAB solution in the reactor to Below 280K, pure TBAB hydrate solids are generated, and the mass concentration of TBAB hydrate solids in the slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com