Pd-based composite nano particle and preparation method thereof

A composite nanoparticle and nanoparticle technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of limited modification of electrode conductivity and limited electron transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

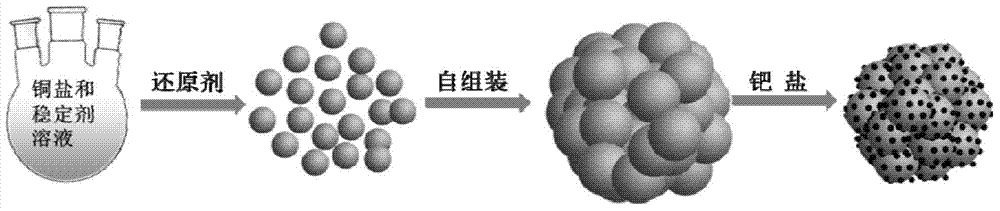

[0025] refer to figure 1 , the preparation method of the Pd-based composite nanoparticles of one embodiment, comprising the steps of:

[0026] S10. Prepare a mixed solution containing copper salt and stabilizer.

[0027] The concentration of the copper salt is 0.0005mol / L-0.005mol / L, and the molar ratio of the stabilizer to the copper salt is 1:1-10.

[0028] Preferably, the concentration of the stabilizer is 0.0001mol / L-0.05mol / L.

[0029] Stabilizers can be citric acid, cetyltrimethylammonium bromide or polyvinylpyrrolidone.

[0030] The copper salt may be copper chloride or copper sulfate.

[0031] S20. After uniformly stirring the mixed solution obtained in S10 at room temperature for 5 to 10 minutes, add a reducing agent to the mixed solution according to the molar ratio of the reducing agent to copper ions of 1 to 100:1, and then react fully according to the palladium salt and copper salt. Add the palladium salt solution at a molar ratio of 1:5-50, and continue to st...

Embodiment 1

[0043]Add 50mL of 0.0005mol / L copper chloride solution into a 100mL single-necked flask, and then add polyvinylpyrrolidone, the concentration of polyvinylpyrrolidone in the solution is 0.001mol / L. After stirring at room temperature for 5 minutes, 0.02 mL wt of 85% hydrazine hydrate was quickly injected into it. After reacting for 10 minutes, the copper ions are fully reduced and the hydrazine hydrate is fully decomposed, then quickly inject 0.5mL of 0.01mol / L palladium chloride solution into the synthesis solution; after keeping stirring for 10 minutes, the synthesis solution in the flask is deionized Centrifuge with water and ethanol, wash and dry in vacuum to obtain Pd-based composite nanoparticles.

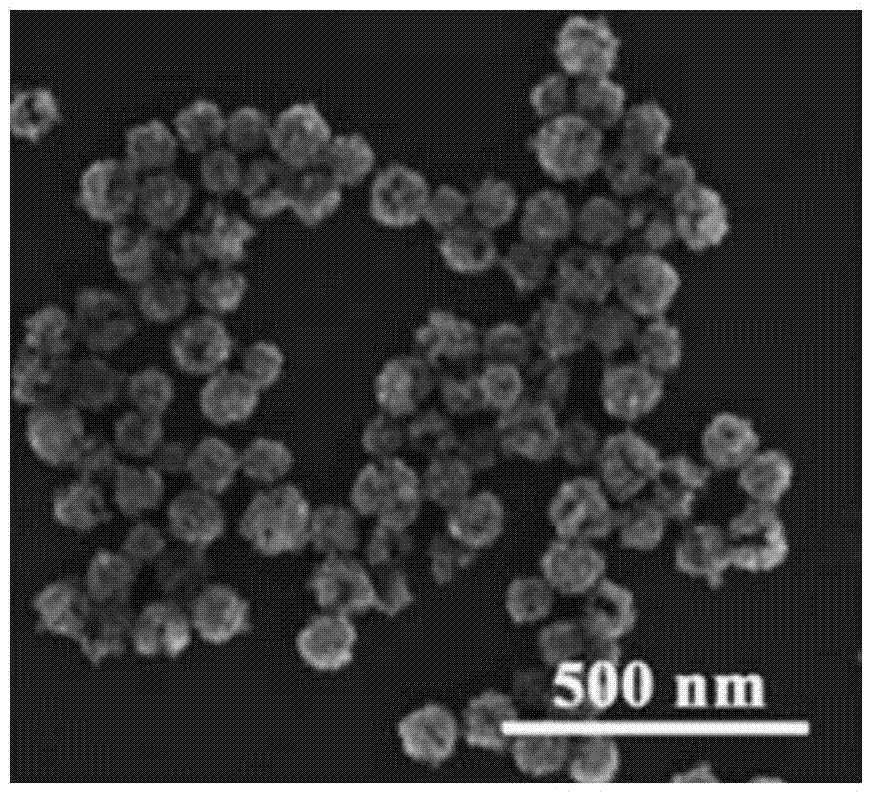

[0044] Such as figure 2 As shown, the Pd-based composite nanoparticles prepared in Example 1 have a mesoporous nanostructure and a rough surface nanostructure, and have uniform size, good monodispersity, and an average particle size of about 90 nm.

[0045] Pure mesoporous C...

Embodiment 2

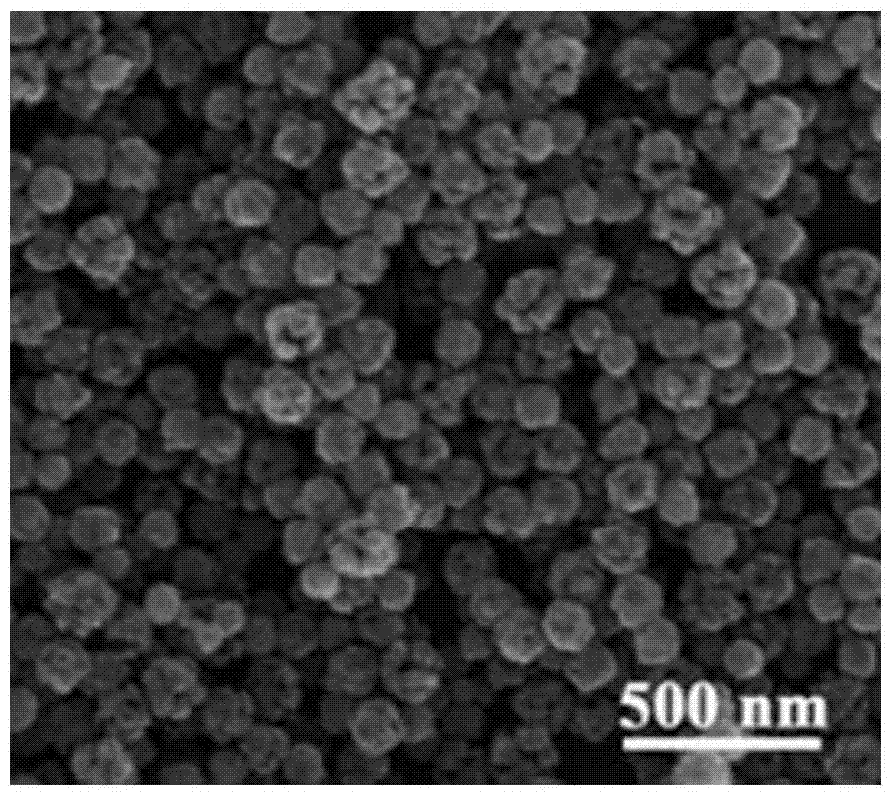

[0051] Add 50mL of 0.001mol / L copper sulfate solution into a 100mL single-necked flask, and then add polyvinylpyrrolidone, the concentration of polyvinylpyrrolidone in the solution is 0.004mol / L. After stirring at room temperature for 5 minutes, 0.05 mL of 85 wt% hydrazine hydrate was quickly injected thereinto. After reacting for 10 minutes, the copper ions are fully reduced and the hydrazine hydrate is fully decomposed, then quickly inject 0.5mL of 0.01mol / L palladium chloride solution into the synthesis solution; after keeping stirring for 10 minutes, the synthesis solution in the flask is deionized Centrifuged with water and ethanol, washed and dried in vacuum to obtain Pd-modified Cu 2 O nanoparticles.

[0052] Electron microscope observation shows that the Pd-based composite nanoparticles prepared in Example 2 have mesoporous nanostructures and rough surface nanostructures, and are uniform in size and good in monodispersity, with an average particle size of about 105 nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com