Process for synthesizing analcite from potassium feldspar powder by virtue of hydro-thermal alkaline method

A technology of potassium feldspar powder and synthesis method, applied in the direction of crystalline aluminosilicate zeolite, alkali metal silicate, silicate, etc., to achieve the effect of reducing raw material cost, improving economic benefit and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

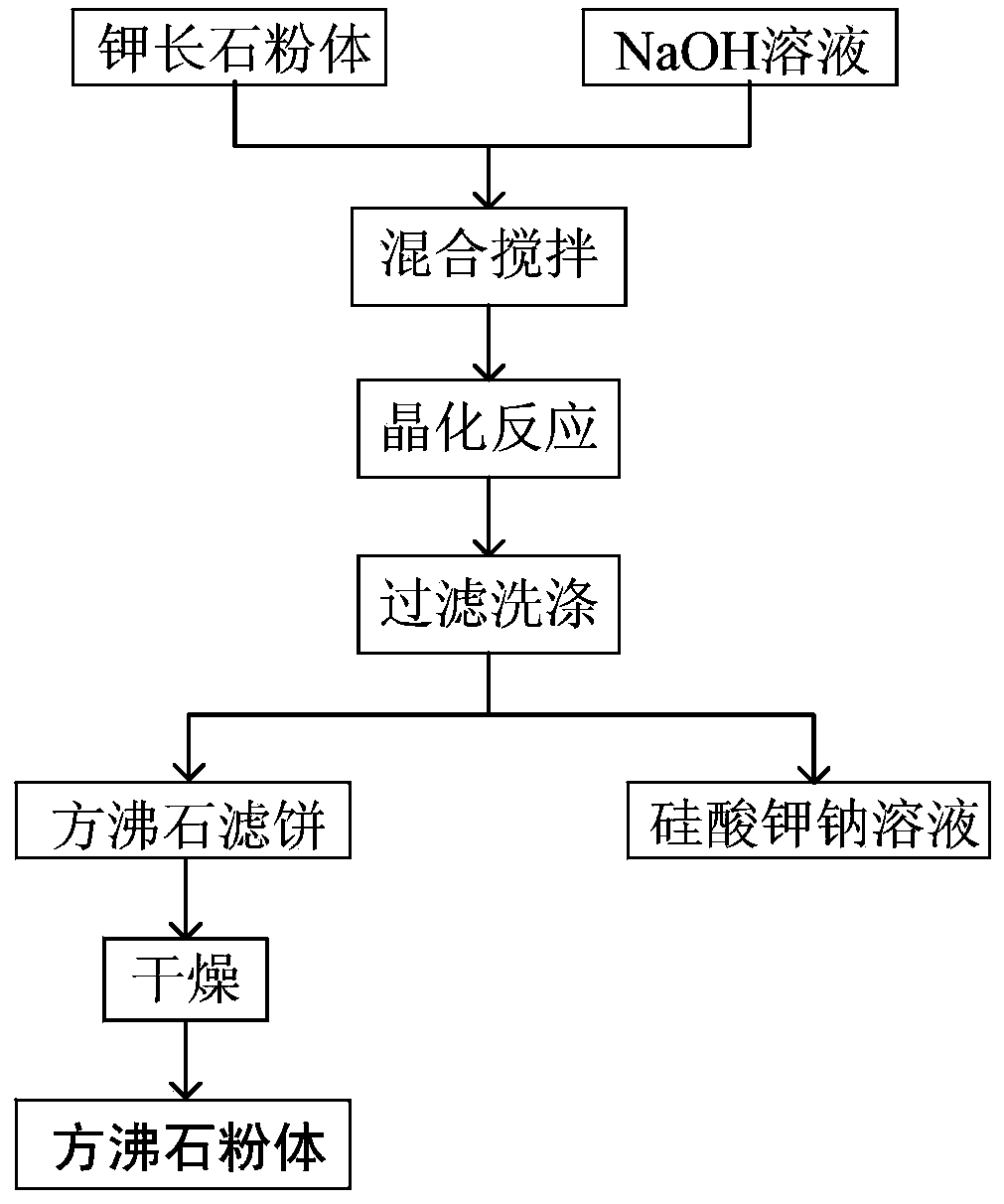

Method used

Image

Examples

Embodiment 1

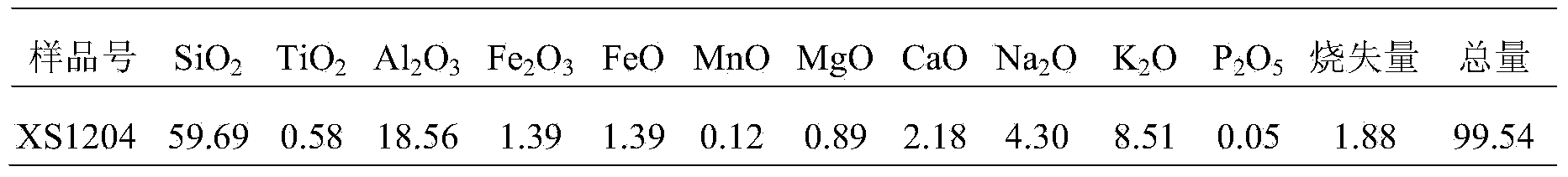

[0033] The raw potash feldspar ore is crushed, ground, and beneficiated to obtain potash feldspar powder raw materials. The chemical composition is as follows (%):

[0034] Table 1 Chemical composition analysis results of potash feldspar powder (w B %)

[0035]

[0036] The main phase composition of the potash feldspar mineral powder is: potash feldspar 69%.

[0037] Mix the potash feldspar powder raw material, sodium hydroxide and distilled water according to the ratio (the concentration of sodium hydroxide solution is 2M, the mass ratio of sodium hydroxide solution / potash feldspar powder = 1:2), and after fully stirring, the mixture slurry Transfer to a 1000mL autoclave, heat to 260℃, keep constant temperature for 3 hours, cool to room temperature naturally, filter, wash 4~5 times until the pH of the lotion is 7~8, put the filter cake in an oven, and dry at 105 ℃, time 16-24h, get a solid sample, the solid sample is analcime.

Embodiment 2

[0039] The raw potash feldspar ore is crushed, ground, and beneficiated to obtain potash feldspar powder raw materials. The chemical composition is as follows (%):

[0040] Table 1 Chemical composition analysis results of potash feldspar powder (w B %)

[0041]

[0042] The main phase composition of the potash feldspar mineral powder is: potash feldspar 69%.

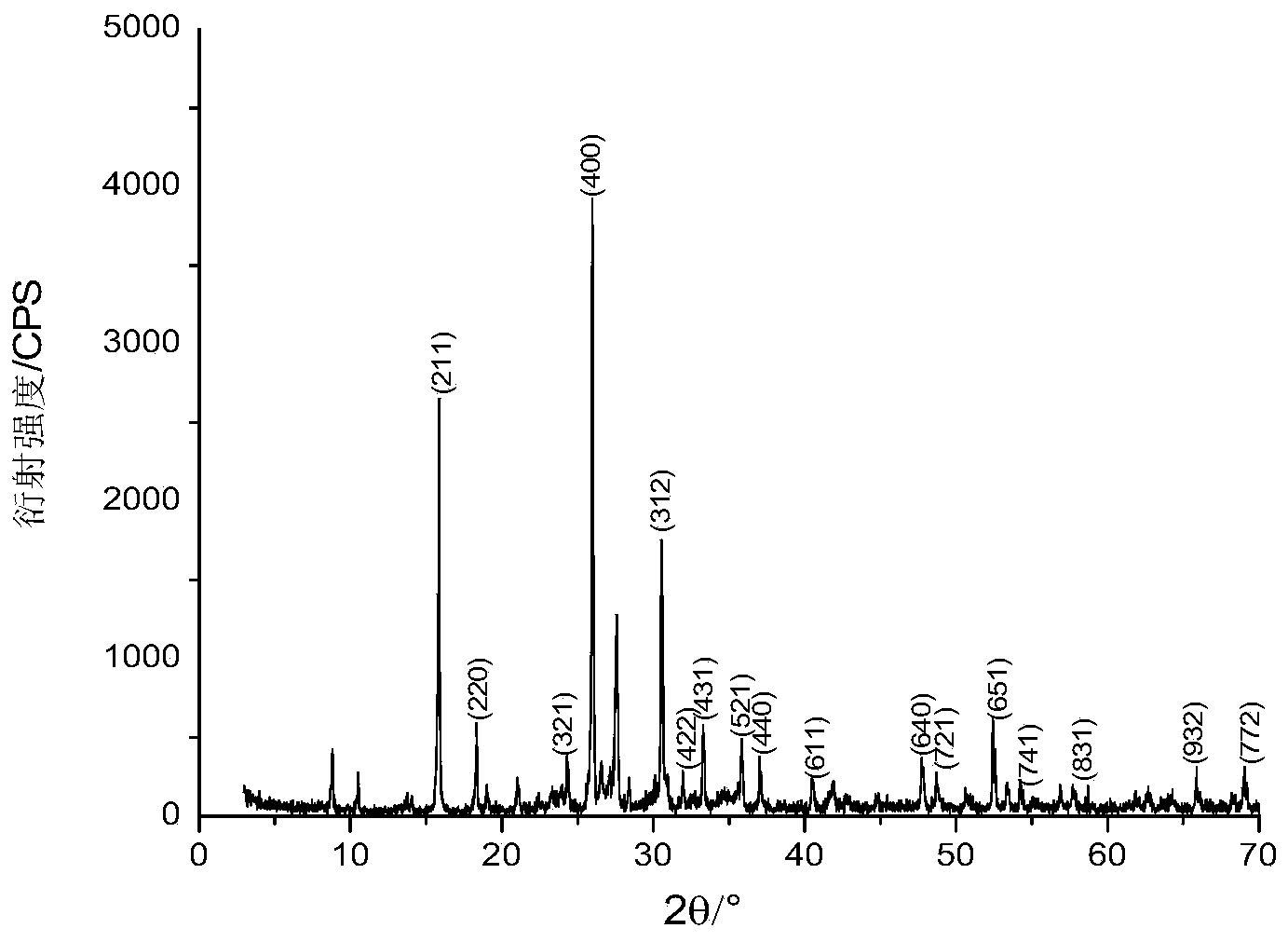

[0043] Mix the potash feldspar powder raw materials, sodium hydroxide and distilled water according to the proportion (the concentration of sodium hydroxide solution is 6M, the mass ratio of sodium hydroxide solution / potash feldspar powder = 1:10), and after fully stirring, the mixture slurry Transfer to a 1000mL autoclave, heat to 260℃, keep constant temperature for 8 hours, cool to room temperature naturally, filter, wash 4~5 times until the pH of the lotion is 7~8, put the filter cake into the oven, and dry at 105 ℃, time 16-24h, get a solid sample, the solid sample is analcime. The chemical composition (Table 2) and phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com