Preparation method of mesoporous TiO2 foam with macro morphology

A foam and mesoporous technology, applied in the field of preparation of mesoporous TiO2 foam, can solve problems such as complicated operation, and achieve the effect of simple production method, strong macroscopic effect and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

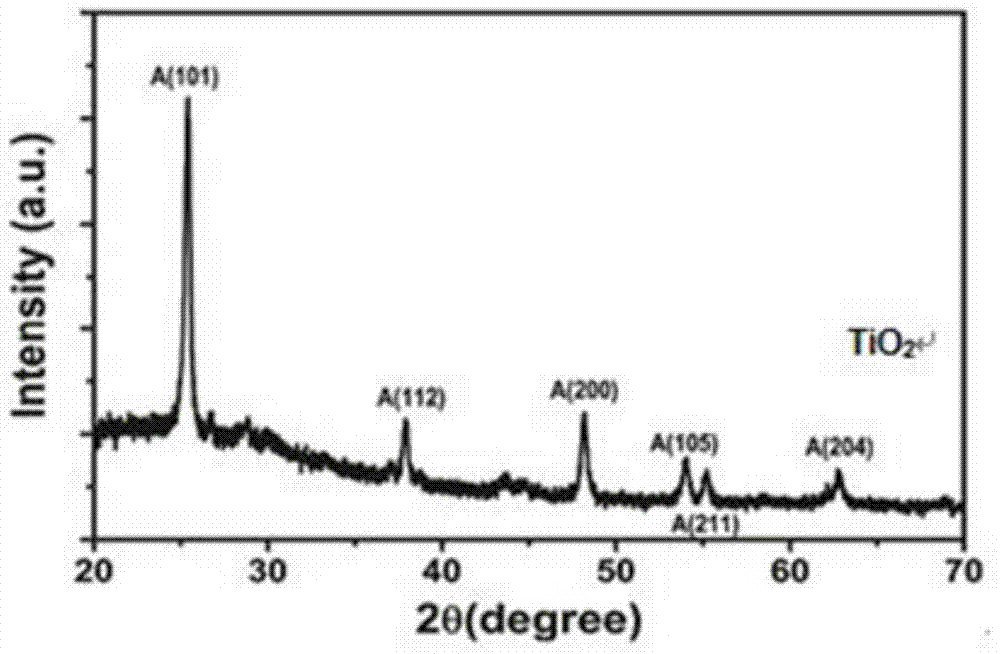

[0029] A mesoporous TiO 2 Foam columns whose main component is TiO 2 Nanobelts, the specific preparation process steps are as follows:

[0030] Step (1): Preparation of sodium titanate nanoribbons

[0031] Add 1.0g Ti(OC 4 h 9 ) 4 , 16g NaOH and 35mL deionized water, after ultrasonic stirring and mixing evenly, let stand for 2 hours, heat and react in an oven at 200°C for 40 hours, then cool to room temperature naturally, a titanium Sodium titanate nanobelts are self-assembled regular disk-shaped solids, which are taken out and washed with deionized water until neutral to obtain sodium titanate nanobelts;

[0032] Wherein: the sodium titanate nanobelt has a length of 2mm, a width of 85nm, and a thickness of 20nm; the disc-shaped solid has a diameter of 3cm, a thickness of 4mm, and a mass of 0.19g;

[0033] Step (2): Mesoporous TiO 2 foam preparation

[0034] Add 1.0g Ti(OC 4 h 9 ) 4 , 0.1g sodium titanate nanoribbons, 12g NaOH and 35mL deionized water, ultrasonicall...

Embodiment 2

[0037] A mesoporous TiO 2 Foam columns whose main component is TiO 2 Nanobelts, the specific preparation process steps are as follows:

[0038] Step (1): Preparation of sodium titanate nanoribbons

[0039] Add 0.9g Ti(OC 4 h 9 ) 4 , 12g NaOH and 35mL deionized water, after ultrasonic stirring and mixing evenly, let it stand for 4 hours, heat and react in an oven at 180°C for 48 hours, then cool to room temperature naturally, a titanium Sodium titanate nanobelts are self-assembled regular disk-shaped solids, which are taken out and washed with deionized water until neutral to obtain sodium titanate nanobelts;

[0040] Wherein: the sodium titanate nanobelt has a length of 1.5mm, a width of 80nm, and a thickness of 20nm; the disc-shaped solid has a diameter of 3.5cm, a thickness of 3mm, and a mass of 0.18g;

[0041] Step (2): Mesoporous TiO 2 foam preparation

[0042] Add 1.1g Ti(OC 4 h 9 ) 4 , 0.1g sodium titanate nanoribbons, 14g NaOH and 35mL deionized water, ultrason...

Embodiment 3

[0045] A mesoporous TiO 2 Foam columns whose main component is TiO 2 Nanobelts, the specific preparation process steps are as follows:

[0046] Step (1): Preparation of sodium titanate nanoribbons

[0047] Add 0.8g Ti(OC 4 h 9 ) 4 , 14g NaOH and 35mL deionized water, after ultrasonic stirring and mixing evenly, let it stand for 3 hours, heat and react in an oven at 230°C for 36 hours, then cool to room temperature naturally, a titanium Sodium titanate nanobelts are self-assembled regular disk-shaped solids, which are taken out and washed with deionized water until neutral to obtain sodium titanate nanobelts;

[0048] Wherein: the sodium titanate nanoribbon has a length of 1mm, a width of 75nm, and a thickness of 15nm; the disc-shaped solid has a diameter of 2cm, a thickness of 5mm, and a mass of 0.17g;

[0049] Step (2): Mesoporous TiO 2 foam preparation

[0050] Add 1.2g Ti(OC 4 h 9 ) 4 , 0.15g of sodium titanate nanoribbons, 16g of NaOH and 35mL of deionized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com