Waste drilling mud non-floor type innocent treatment system and treatment method

A technology of harmless treatment and waste mud, applied in sludge treatment, mining wastewater treatment, chemical instruments and methods, etc., can solve environmental and cultivated land pollution, unfavorable environmental protection and sustainable development, and restrict oil field drilling, etc. Achieve the effects of reducing pollution discharge, preventing harmful pollutants from penetrating into the formation, and shortening the operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

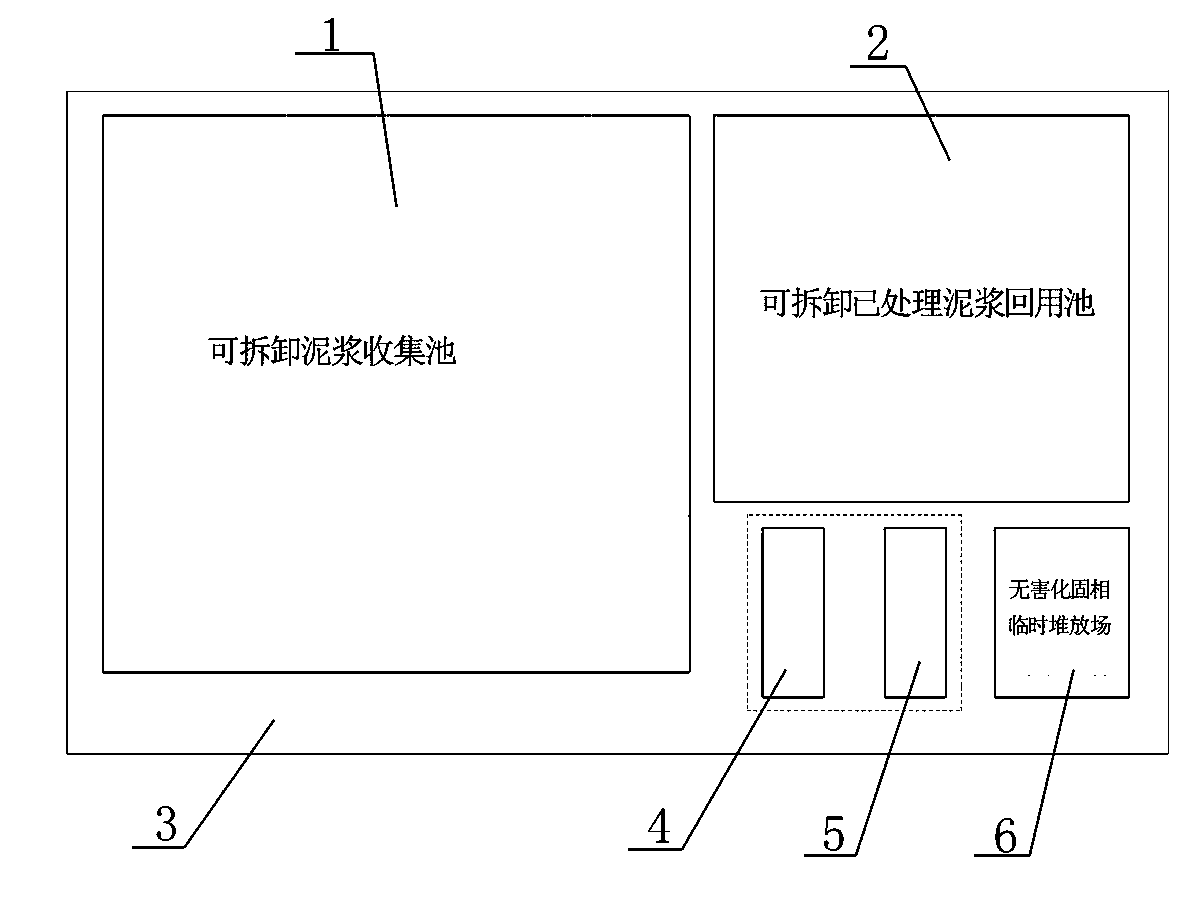

[0047] see figure 1 The harmless treatment system for drilling waste mud without falling to the ground of the present invention includes a detachable mud collection tank 1, vehicle-mounted mud treatment devices 4, 5, an anti-seepage ground layer 3 at the treatment site, a harmless solid phase temporary storage site for mud 6 and The treated mud reuse pool 2 is detachable, wherein: the anti-seepage ground layer of the treatment site is a composite anti-seepage membrane formed by hot-pressing the anti-seepage film and the anti-seepage film.

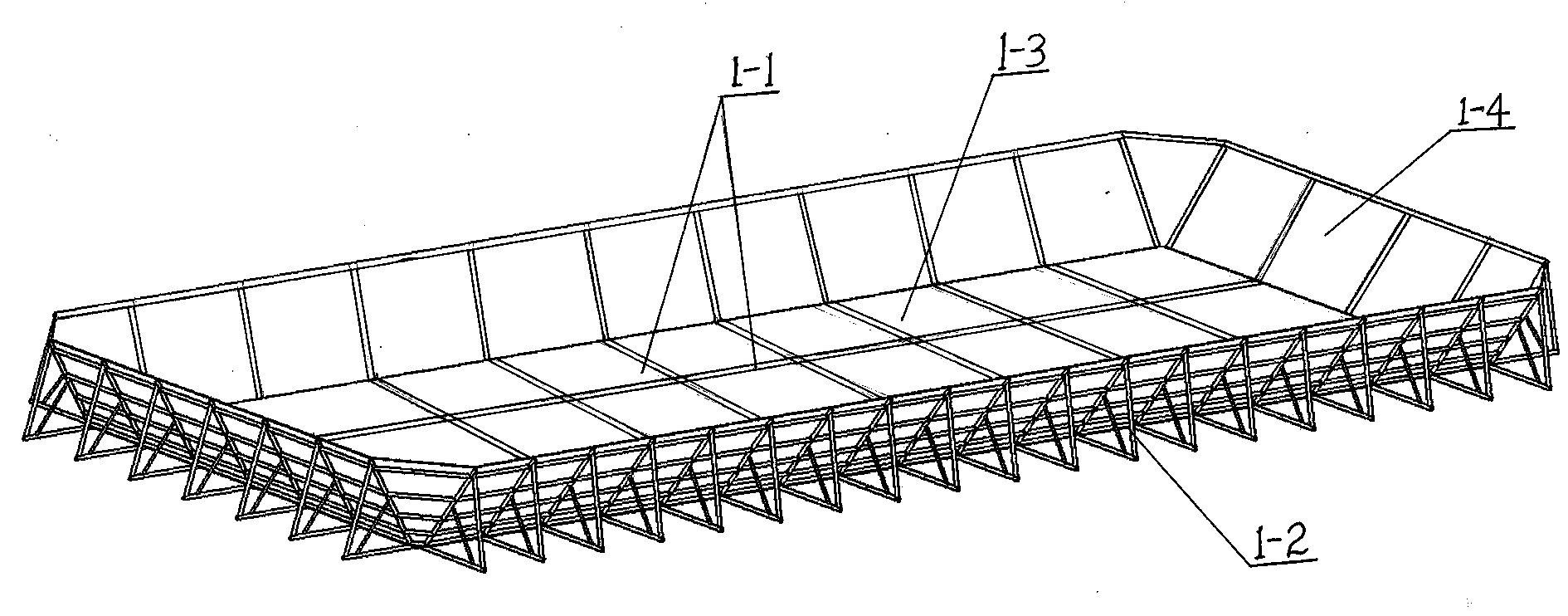

[0048] see figure 2 , the detachable mud collection tank and the detachable treated mud reuse tank of the present invention are composed of a combined bottom frame 1-1, a peripheral side wall frame 1-2, a pool bottom plate 1-3 and a pool wall plate 1-4 The pool bottom plate 1-3 is made of bamboo board or plastic plate, the bottom frame 1-1 and the surrounding side wall frame 1-2 are all metal components, and the pool bottom plate 1-3 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com