Perampanel crystal form a and preparation method thereof

A technology of crystal form and material crystal, applied to the crystal form of perampanel and the field of preparation thereof, can solve problems such as toxicity and environmental pollution, and achieve the effects of improved solubility, low cost and high solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The preparation method of perampanel crystal form A:

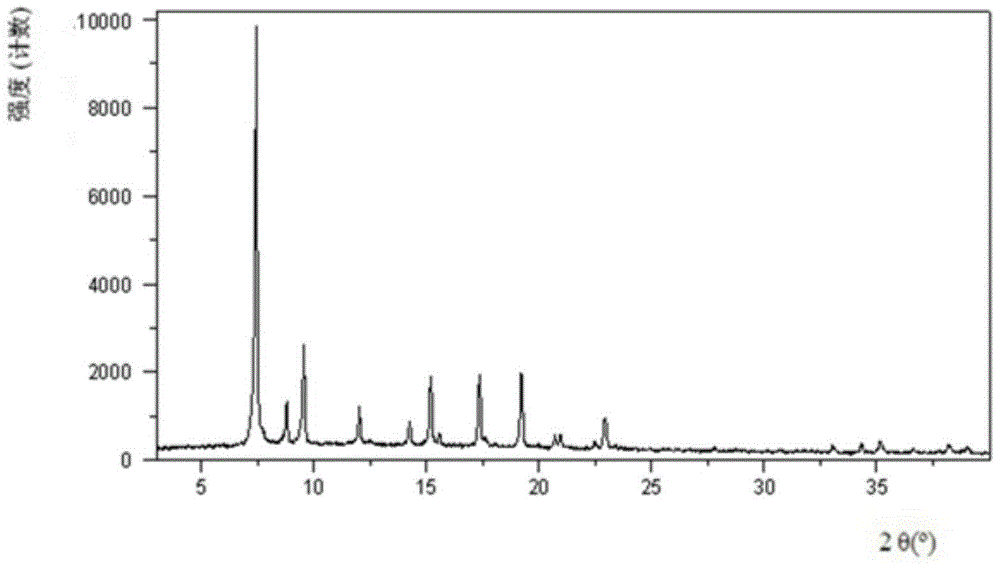

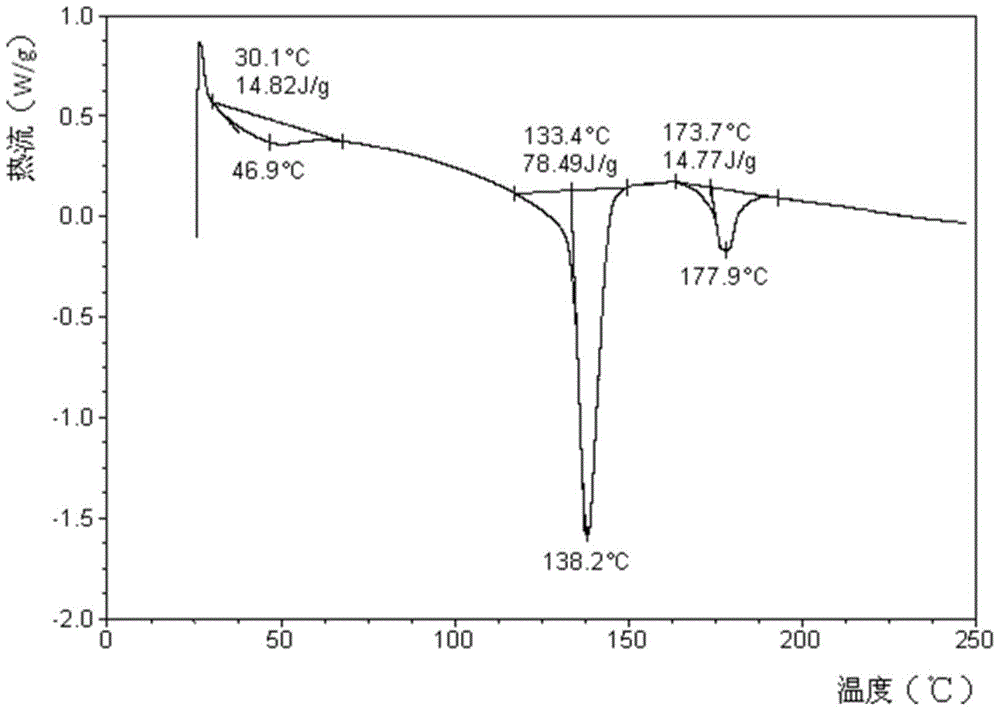

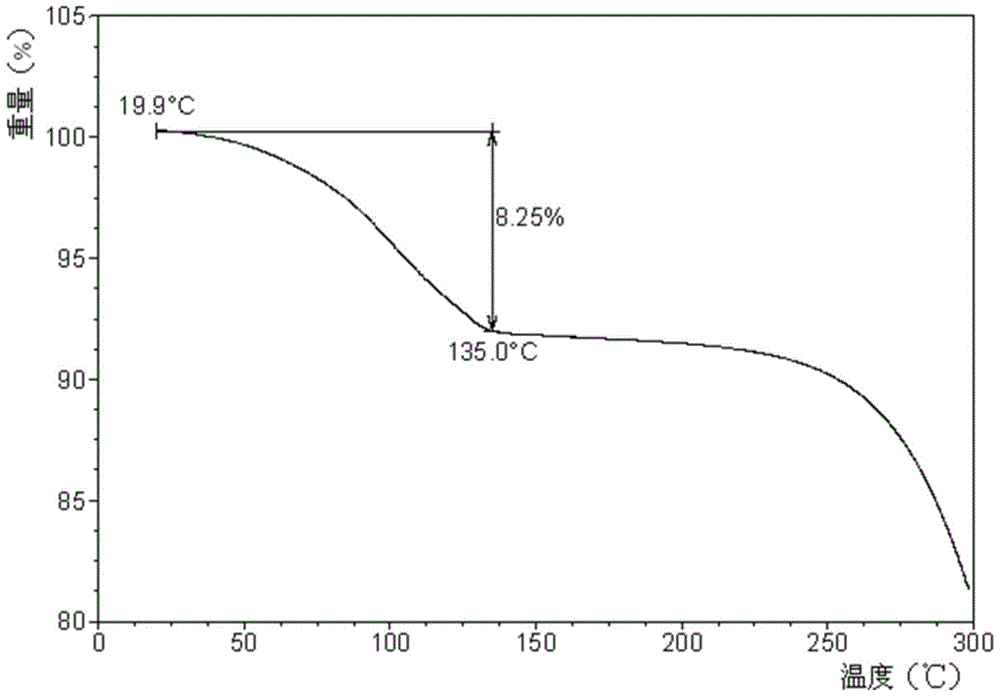

[0053] Add 50.1 mg of perampanel powder into 2.0 mL of a mixed solvent of acetic acid and water at a volume ratio of 1:1 to obtain a clear solution. Suspend and stir the solution for 1 day at room temperature, separate the solid by centrifugation, and dry it in vacuum for 24 After 1 hour, the solid was collected to obtain Form A. Table 1 shows the X-ray powder diffraction data of Form A obtained in this example. After testing its XRPD pattern and figure 1 Consistent, its DSC plot is consistent with figure 2 Consistent, its TGA diagram is consistent with image 3 unanimous.

[0054] Table 1 X-ray powder diffraction data of Form A

[0055] 2theta d interval strength% 7.44 11.89 100.00 8.79 10.07 10.25 9.55 9.27 24.10 12.01 7.37 9.72 14.23 6.22 5.24 15.18 5.84 16.74 15.56 5.70 3.24 17.35 5.11 17.50 19.20 4.62 18.09 20.70 4.29 2.96 22.93...

Embodiment 2

[0057] The preparation method of perampanel crystal form A:

[0058] Dissolve 10.3 mg of perampanel powder in 0.7 mL of a mixed solvent of acetic acid and water at a volume ratio of 5:2 to obtain a clear solution, heat the solution to 50°C, then slowly cool down to 5°C, and solids precipitate out. After vacuum drying for 24 hours, the solid was collected to obtain Form A. Table 2 shows the X-ray powder diffraction data of Form A obtained in this example.

[0059] Table 2 X-ray powder diffraction data of crystal form A

[0060] 2theta d interval strength% 7.43 11.90 100.00

[0061] 8.78 10.07 16.11 9.54 9.27 30.15 12.00 7.38 9.62 14.23 6.22 5.86 15.18 5.84 20.60 17.33 5.12 15.66 19.19 4.62 15.89 20.84 4.26 2.05 22.91 3.88 6.45 24.29 3.66 1.86 34.31 2.61 1.65 35.14 2.55 1.79 38.20 2.36 1.68

Embodiment 3

[0063] The preparation method of perampanel crystal form A:

[0064] Add 10.0 mg of perampanel powder to 0.5 mL of acetic acid and water in a mixed solvent with a volume ratio of 1:1 to obtain a suspension solution. Suspend and stir the solution for 1 day at room temperature, separate the solid by centrifugation, and dry in vacuo After 12 hours, the solid was collected to obtain Form A. Table 3 shows the X-ray powder diffraction data of Form A obtained in this example.

[0065] Table 3 X-ray powder diffraction data of Form A

[0066] 2theta d interval strength% 7.46 11.85 100.00 8.82 10.03 17.28 9.57 9.24 39.80 12.03 7.35 11.21 14.29 6.20 6.83 15.21 5.82 24.87 15.58 5.69 4.06 17.36 5.11 22.06 19.21 4.62 20.94 20.71 4.29 2.71 20.98 4.23 4.44 22.93 3.88 8.29 33.05 2.71 1.71 34.30 2.61 2.38

[0067] 35.14 2.55 3.06 38.18 2.36 2.31 39.04 2.31 1.41

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com