Green-yellow light LED with doped wide potential barrier structure

A yellow-green light, potential barrier technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as low internal quantum efficiency, and achieve the effect of improving hole injection, improving product light efficiency, and improving product process window.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

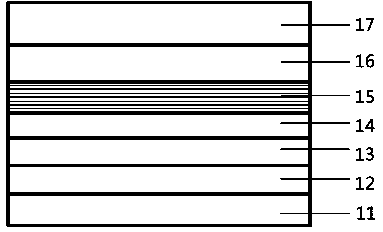

[0014] 1. Production process steps:

[0015] 1. Place the N-GaAs substrate 21 in the MOCVD reaction chamber, heat it to 600° C. to 700° C., remove the oxide layer on the substrate surface, and grow the GaAs buffer layer 22 .

[0016] 2. Growing a Bragg reflection layer 23 on the GaAs buffer layer 22 .

[0017] 3. Growing an N-type confinement layer 24 on the Bragg reflection layer 23 .

[0018] 4. Grow the first active layer 25 of non-doped superlattice on the N-type confinement layer 24: with Al X Ga (1-X) InP / Al Y Ga (1-Y) InP is the material, where X takes a value of 0.3, Y takes a value of 0.7, a period thickness of 10 nm, and a logarithm of 30 pairs.

[0019] 5. Al on the first active layer 25 Y Ga (1-Y) InP is used as a material, doped with impurities of the same conductivity type, and a wide barrier structure layer 26 is grown.

[0020] In this embodiment, the value of Y is 0.7, the thickness is 80nm, the doping element is Zn, and the doping concentration is 5E1...

Embodiment 2

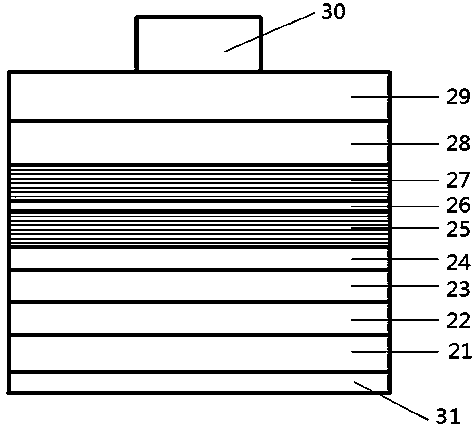

[0033] 1. Production process steps:

[0034] 1. Place the N-GaAs substrate 21 in the MOCVD reaction chamber, heat it to 600° C. to 700° C., remove the oxide layer on the substrate surface, and grow the GaAs buffer layer 22 .

[0035] 2. Growing a Bragg reflection layer 23 on the GaAs buffer layer 22 .

[0036] 3. Growing an N-type confinement layer 24 on the Bragg reflection layer 23 .

[0037] 4. Grow the first active layer 25 of non-doped superlattice on the N-type confinement layer 24: with Al X Ga (1-X) InP / Al Y Ga (1-Y) InP is the material, where X takes a value of 0.35, Y takes a value of 0.6, a period thickness of 10 nm, and a logarithm of 30 pairs.

[0038] 5. Al on the first active layer 25 Y Ga (1-Y) InP is used as a material, doped with impurities of the same conductivity type, and a wide barrier structure layer 26 is grown.

[0039] In this embodiment, the value of Y is 0.6, the thickness is 150 nm, the doping element is Mg, and the doping concentration is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Dominant wavelength | aaaaa | aaaaa |

| Dominant wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com