Preparation method of intelligent controlled release essence capsule

A flavor capsule and intelligent control technology, which is applied in the direction of microcapsule preparation, microsphere preparation, essential oil/fragrance, etc., can solve the problems of single function and reduction, achieve objective application prospects, avoid sudden release, and prolong the effective time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Weigh 200g of cetyl acrylate, 2g of azobisisobutyronitrile and 200g of lavender essential oil and mix them uniformly to obtain an oil phase solution.

[0018] (2) Pour the above oil phase solution into 5kg of styrene-maleic anhydride copolymer salt solution with a mass concentration of 5wt%, and high-speed shear emulsification to prepare a stable emulsion with a particle size of about 10 μm.

[0019] (3) Stir the stable emulsion obtained in step (2) at a stirring speed of 500rpm, and at the same time raise the temperature to 75°C to initiate polymerization, and keep it for 3 hours to obtain a fragrance capsule with polyhexadecyl acrylate as the capsule wall suspension. After the suspension is filtered, washed and dried, capsule powder can be obtained.

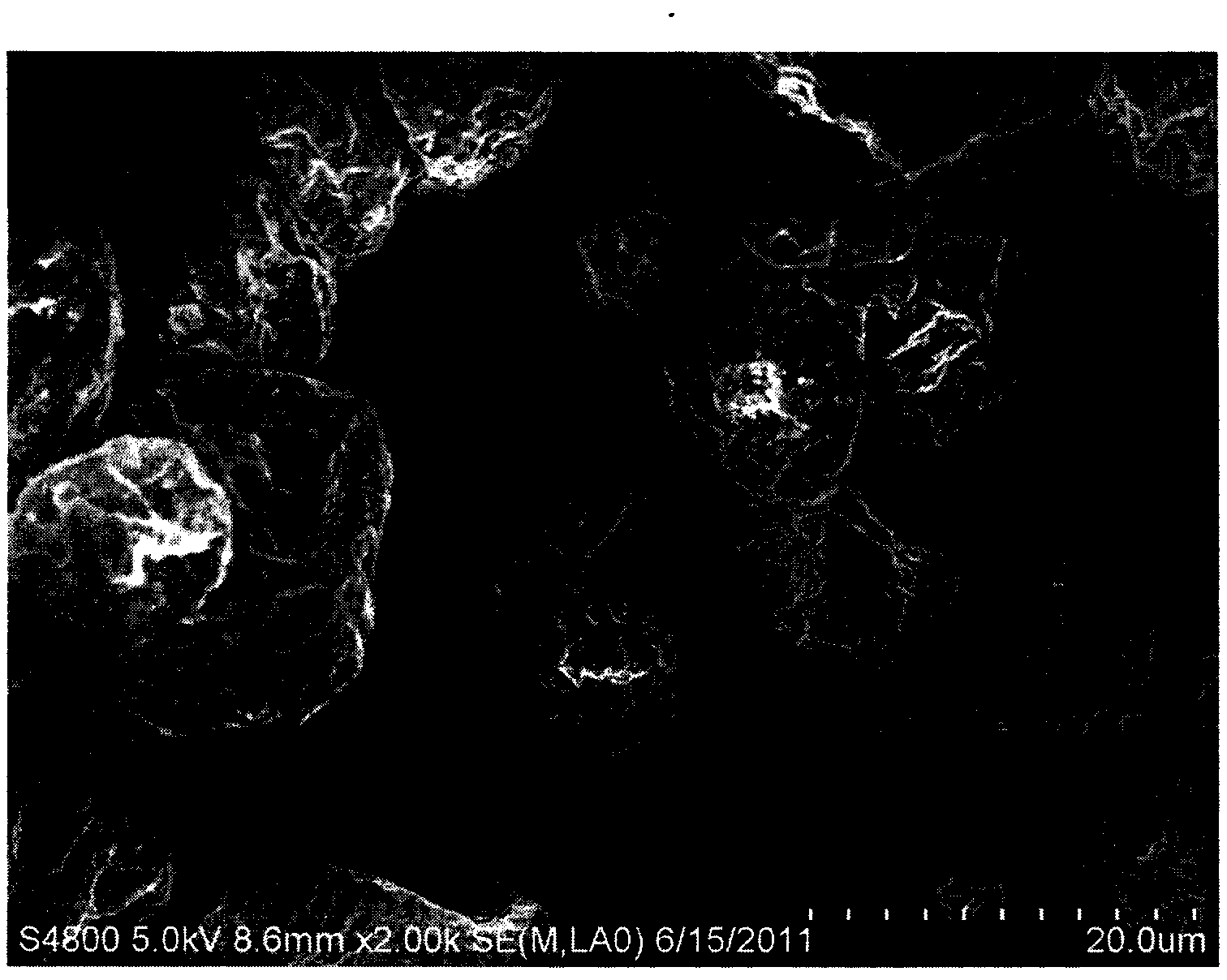

[0020] figure 1 For the prepared polyhexadecyl acrylate aromatic capsules, it can be seen that the particle size distribution of the spherical capsules is in the range of 4 μm to 20 μm, and the average particle siz...

Embodiment 2

[0022] (1) Weigh 1 kg of stearyl acrylate, 100 g of azobisisoheptanonitrile and 10 kg of benzyl benzoate and mix them uniformly to obtain an oil phase solution.

[0023] (2) Pour the oil phase solution in step (1) into 60 kg of gelatin solution with a mass concentration of 10 wt%, and high-speed shear emulsification to prepare a stable emulsion with an average particle size of about 50 μm.

[0024] (3) The stable emulsion obtained in step (2) is heated to 65° C. to initiate polymerization under stirring at 1000 rpm, and kept for 3 hours to obtain a suspension of essence capsules with polyoctadecyl acrylate as the capsule wall. After the suspension is filtered, washed and dried, capsule powder can be obtained.

Embodiment 3

[0026] (1) Weigh 6 kg of tetracosyl methacrylate, 600 g of benzoyl peroxide and 10 kg of jasmine oil and mix them uniformly to obtain an oil phase solution.

[0027] (2) Pour the above oil phase solution into 100kg of OP-10 solution with a mass concentration of 10wt%, and high-speed shear emulsification to prepare a stable emulsion with an average particle size of about 20 μm.

[0028] (3) Heat the stable emulsion obtained in step (2) to 85° C. to initiate polymerization under stirring at 10 rpm, and keep it for 3 hours to obtain a suspension of essence capsules with polytetracosyl acrylate as the capsule wall. After the suspension is filtered, washed and dried, capsule powder can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com