Preparation method of MoS2 / Ag2S nano-composite photocatalytic material

A photocatalytic material and nanocomposite technology, which is applied in the field of preparation of MoS2/Ag2S nanocomposite photocatalytic materials, can solve the problems of low utilization rate of sunlight and achieve simple and easy preparation method, high yield and good dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Dissolve 0.160 g of molybdenum disulfide in 40 mL of water. After ultrasonic dispersion and dissolution, add 0.2 g of polyvinylpyrrolidone and stir rapidly under the action of a magnetic stirrer to obtain a black molybdenum disulfide aqueous solution.

[0024] (2) Dissolve 0.170 g of silver nitrate in 20 mL of water, slowly add dropwise to molybdenum disulfide aqueous solution, stir at room temperature for 2 h, transfer to a stainless steel reactor lined with polytetrafluoroethylene, and keep at 180 °C 24 h; then centrifuged to collect the product, washed with deionized water, absolute ethanol, and dried in vacuum to obtain nano-MoS 2 / Ag 2 S.

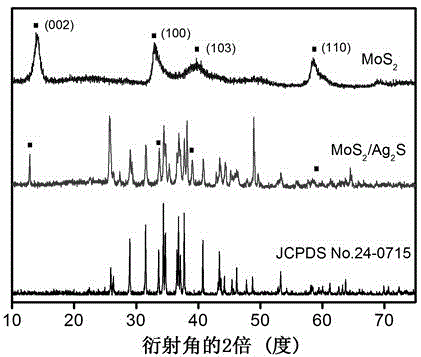

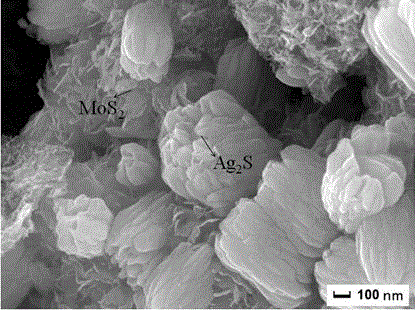

[0025] figure 1 is the MoS prepared in Example 1 2 / Ag 2 XRD pattern of S nanophotocatalytic material, it can be seen from the figure that the nanomaterial is MoS 2 / Ag 2 S composite material, no other substances are present; figure 2 is the MoS prepared in Example 1 2 / Ag 2 Scanning electron microscope image of S ...

Embodiment 2

[0027] (1) Dissolve 0.160 g of molybdenum disulfide in 40 mL of water. After ultrasonic dispersion and dissolution, add 0.2 g of polyvinylpyrrolidone and stir rapidly under the action of a magnetic stirrer to obtain a black molybdenum disulfide aqueous solution.

[0028] (2) Dissolve 0.2265g of silver nitrate in 20 mL of water, slowly add dropwise to the molybdenum disulfide aqueous solution, stir at room temperature for 2 h, transfer to a stainless steel reactor lined with polytetrafluoroethylene, and keep at 180°C 24 h; then centrifuged to collect the product, washed with deionized water, absolute ethanol, and dried in vacuum to obtain nano-MoS 2 / Ag 2 S.

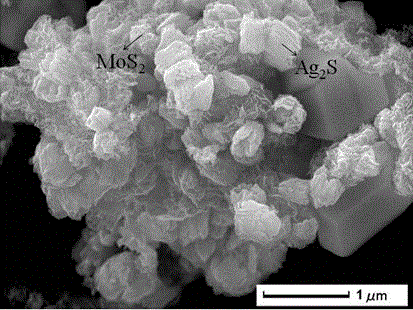

[0029] image 3 is the MoS prepared in Example 2 2 / Ag 2 Scanning electron microscope image of S nano photocatalytic material, from which it can be seen that MoS 2 Showing a flower-like structure, Ag 2 S presents a petal rod shape with small granular block structure.

Embodiment 3

[0031] (1) Dissolve 0.160 g of molybdenum disulfide in 40 mL of water. After ultrasonic dispersion and dissolution, add 0.2 g of polyvinylpyrrolidone and stir rapidly under the action of a magnetic stirrer to obtain a black molybdenum disulfide aqueous solution.

[0032] (2) Dissolve 0.2912 g of silver nitrate in 20 mL of water, slowly add it dropwise to the molybdenum disulfide aqueous solution, stir at room temperature for 2 h, transfer to a stainless steel reactor lined with polytetrafluoroethylene, and keep at 180 °C 24 h; then centrifuged to collect the product, washed with deionized water, absolute ethanol, and dried in vacuum to obtain nano-MoS 2 / Ag 2 S.

[0033] Nano-MoS prepared in Example 3 2 / Ag 2 The scanning electron microscope image of the S nanometer photocatalytic material is similar to that of Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com