A kind of highly stable lactic acid bacteria microcapsules and its preparation method and application

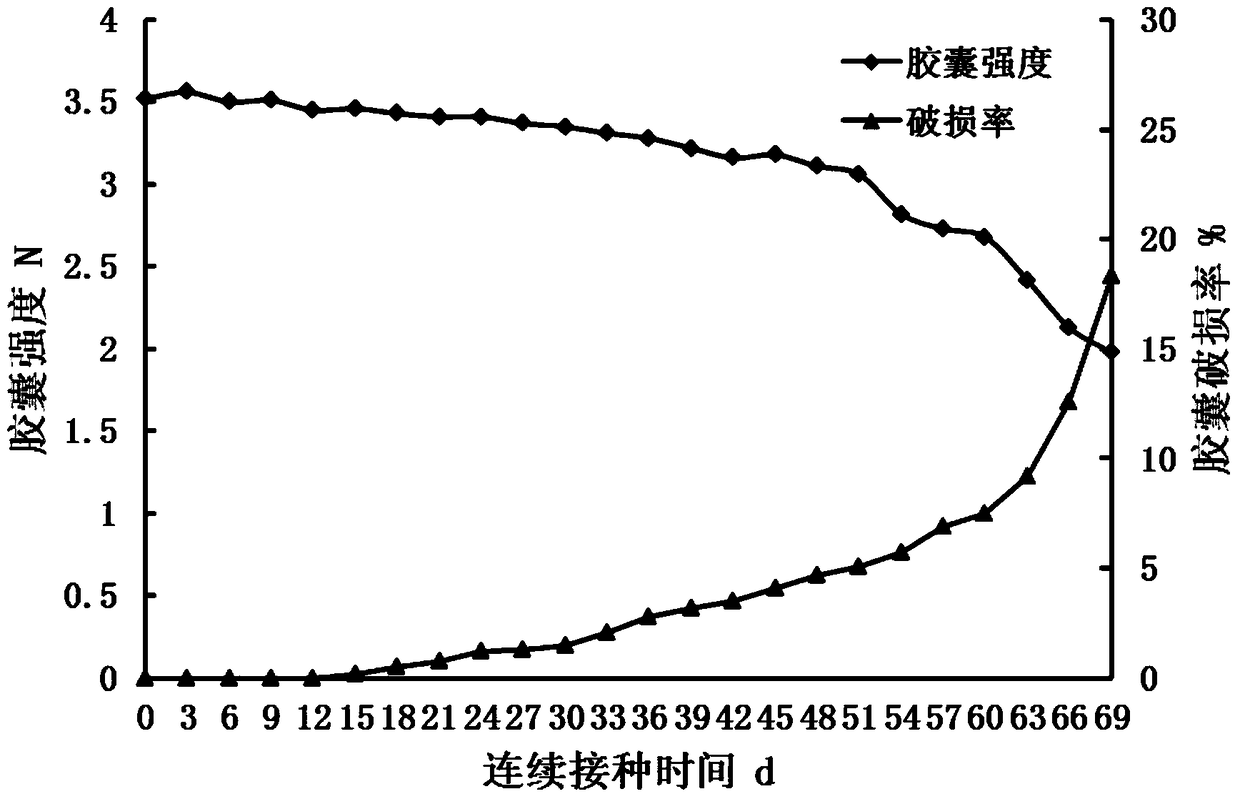

A lactic acid bacteria microcapsule and high stability technology, applied in the field of bioengineering, can solve the problems of weakening microcapsule strength, affecting inoculation efficiency, increasing production cost, etc., to prevent phage infection, improve inoculation efficiency, and reduce unit cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method for highly stable lactic acid bacteria microcapsules, comprising the steps of:

[0041] (1) Inoculate the freeze-dried lactic acid bacteria into the MRS medium to activate the bacteria twice.

[0042] (2) Inoculate the strain activated in step (1) into whey medium or MRS medium, and culture at 37° C. for 18 hours.

[0043] (3) The fermented liquid obtained in step (2) is centrifuged (5000rpm, 10min) and discarded to remove the supernatant, and the remaining bacteria are suspended in sterile trehalose aqueous solution, mixed with calcium lactate, sodium caseinate and gelatin-free Bacteria mixed aqueous solution is mixed evenly; In the described trehalose aqueous solution, the solute trehalose mass percent concentration is 0.5%; The mass ratio of the bacteria body to the sterile trehalose aqueous solution is 35%; In the sterile mixed aqueous solution of gelatin, the mass percentage concentration of solute calcium lactate is 4%, the mass percentage co...

Embodiment 2

[0056] A preparation method for highly stable lactic acid bacteria microcapsules, comprising the steps of:

[0057] (1) Inoculate the freeze-dried lactic acid bacteria into the MRS medium to activate the bacteria twice.

[0058] (2) Inoculate the strain activated in step (1) into whey medium or MRS medium, and culture at 30° C. for 20 hours.

[0059] (3) The fermented liquid obtained in step (2) is centrifuged (5000rpm, 10min) and discarded to remove the supernatant, and the remaining bacteria are suspended in sterile trehalose aqueous solution, mixed with calcium lactate, sodium caseinate and gelatin-free Bacteria mixed aqueous solution is mixed; in the described trehalose aqueous solution, the solute trehalose mass percent concentration is 0.6% (preferably 0.5%); the mass ratio of the bacteria to the sterile trehalose aqueous solution is 32%; the calcium lactate, In the sterile mixed aqueous solution of sodium caseinate and gelatin, the mass percentage concentration of solu...

Embodiment 3

[0066] A preparation method for highly stable lactic acid bacteria microcapsules, comprising the steps of:

[0067] (1) Inoculate the freeze-dried lactic acid bacteria into the MRS medium to activate the bacteria twice.

[0068] (2) Inoculate the strain activated in step (1) into whey medium or MRS medium, and culture at 44° C. for 24 hours.

[0069] (3) The fermented liquid obtained in step (2) is centrifuged (5000rpm, 10min) and discarded to remove the supernatant, and the remaining bacteria are suspended in sterile trehalose aqueous solution, mixed with calcium lactate, sodium caseinate and gelatin-free Bacteria mixed aqueous solution is mixed; In the described trehalose aqueous solution, the solute trehalose mass percent concentration is 0.8%; The mass ratio of the bacteria body to the sterile trehalose aqueous solution is 38%; The calcium lactate, sodium caseinate and In the sterile mixed aqueous solution of gelatin, the mass percentage concentration of solute calcium la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com