Heterodyne interferometer vibration measurer based on laser doppler effect

A technology of Doppler effect and heterodyne interference, which is applied in the field of heterodyne interferometric vibrometers, can solve the problem that optical devices cannot be placed in an aligned state, and achieve the effect of avoiding internal structural differences and improving vibration measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

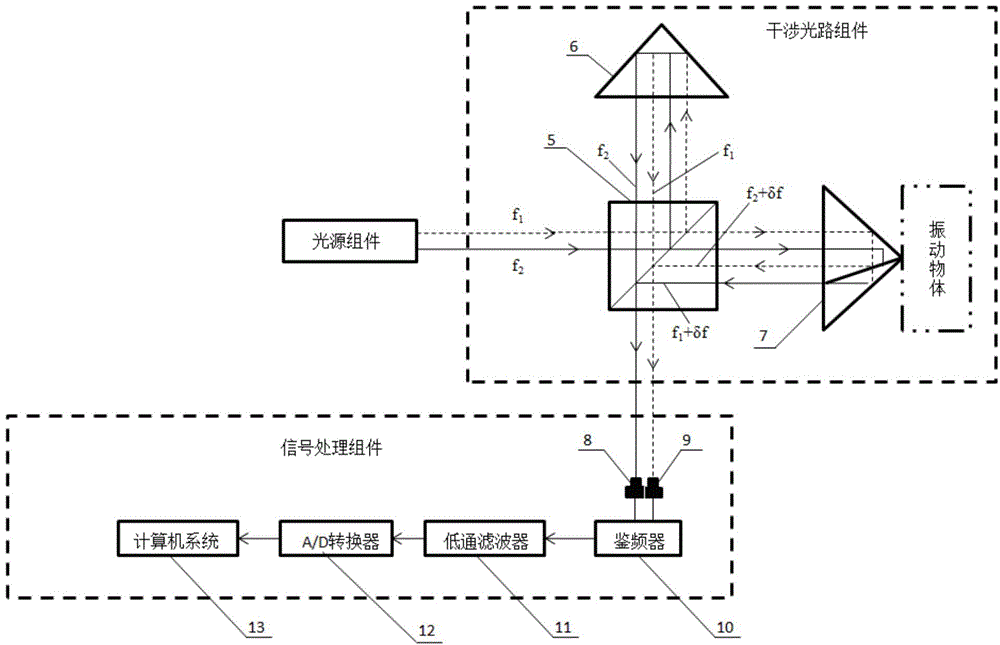

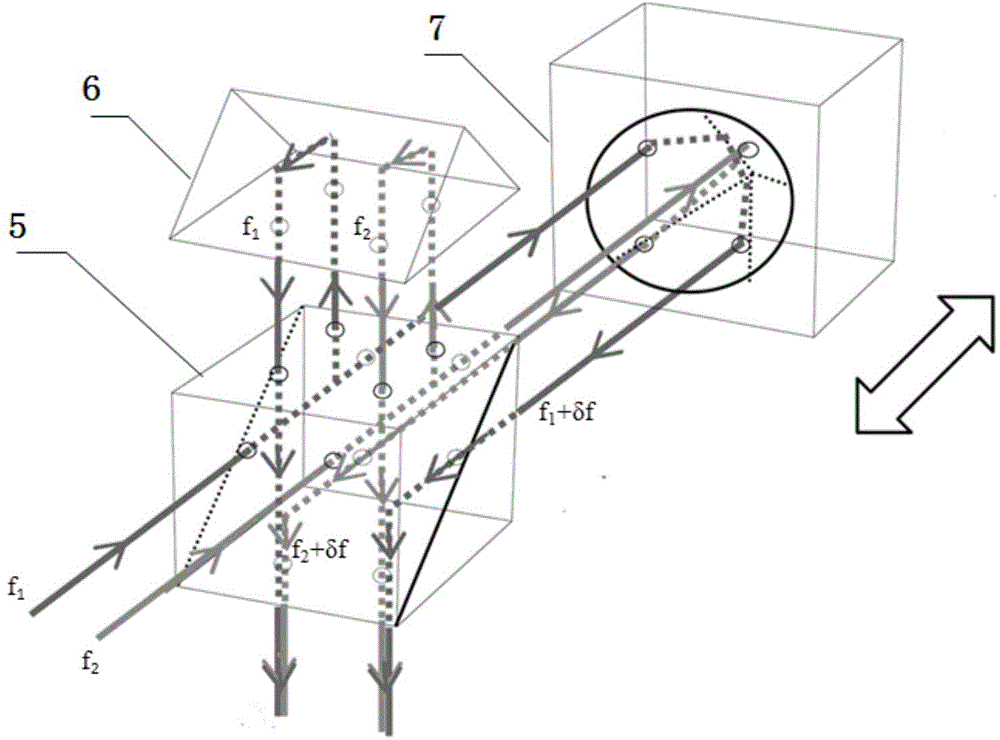

[0033] In this embodiment, the structural schematic diagram of the heterodyne interferometric vibrometer based on the laser Doppler effect is as follows figure 1 , 2 , 3, including light source components, interference optical path components and signal processing components.

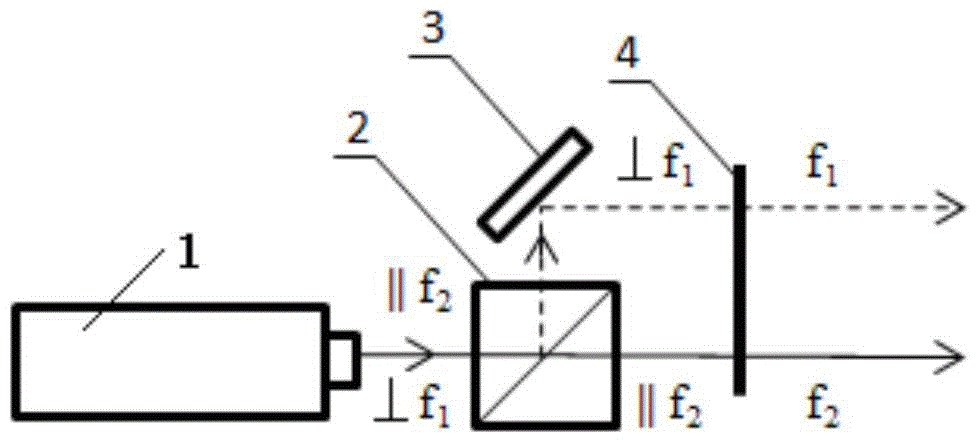

[0034] The light source component is composed of a dual-frequency laser source 1, a polarization beam splitter 2, a reflector 3 and a polarizer 4. The dual-frequency laser source 1 is a transverse Zeeman dual-frequency laser with a frequency difference of 60 MHz, and the emission wavelength is 633 nm. The polarization beam splitter prism 2 is ZF optical glass coated with polarized beam splitting film on the inclined surface, and the four outer surfaces are coated with narrow-band multi-layer anti-reflection film. The applicable wavelength is 633nm. glass), the applicable wavelength is 633nm, and the polarizer 4 is a linear polarizer made of a dichroic material. The structure of the light source assemb...

Embodiment 2

[0038] In this embodiment, the laser Doppler effect-based heterodyne interferometric vibrometer described in Embodiment 1 is used for analog vibration measurement. The measurement method is as follows:

[0039] 1. With the audio equipment as the vibration source, the curved prism 7 in the heterodyne interferometric vibrometer described in Embodiment 1 is fixed in a box, the box is fixed in front of the speaker of the audio equipment and close to the speaker, and the audio equipment The vibration frequency is adjusted to 23Hz.

[0040] 2. Turn on the dual-frequency laser light source 1 in the heterodyne interferometric vibrometer described in Embodiment 1 and make the signal processing components work.

[0041] See the measurement results Figure 5 .

[0042] Comparative Test

[0043] The simulated vibration measurement is performed by using the high-precision dual-frequency simultaneous measurement laser heterodyne interference phase vibrometer optical path disclosed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com