Metal nanowire/carbon nanotube composite transparent conducting film and preparation method thereof

A carbon nanotube composite and metal nanowire technology, which is applied in cable/conductor manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of excessively large gaps in the conductive network, loose bonding of conductive materials, and low sheet resistance, and achieve equipment Simple, low cost, strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Take 0.1g of silver nanowires and 0.01g of carbon nanotubes and mix them in 100mL of absolute ethanol. After ultrasonic dispersion for 20 minutes, a mixed suspension is obtained. The silver nanowires are 70-100nm in diameter and 5-20μm in length. The tubes are 20-40nm in diameter and 2-5μm in length, all purchased from the market without other treatment;

[0036](2) Take 20mL of the suspension to form a uniform film layer on a PET transparent substrate with a thickness of 350 μm and an area of 40cm×40cm by transfer method. The surface density of silver nanowires and carbon nanotubes on the flexible transparent substrate is 0.01375mg / cm 2 ;

[0037] (3) Statically press the film layer together with the PET transparent substrate on a tablet press for 10 seconds under a pressure of 15 MPa to obtain an AgNWs / CNTs-PET composite flexible transparent conductive film.

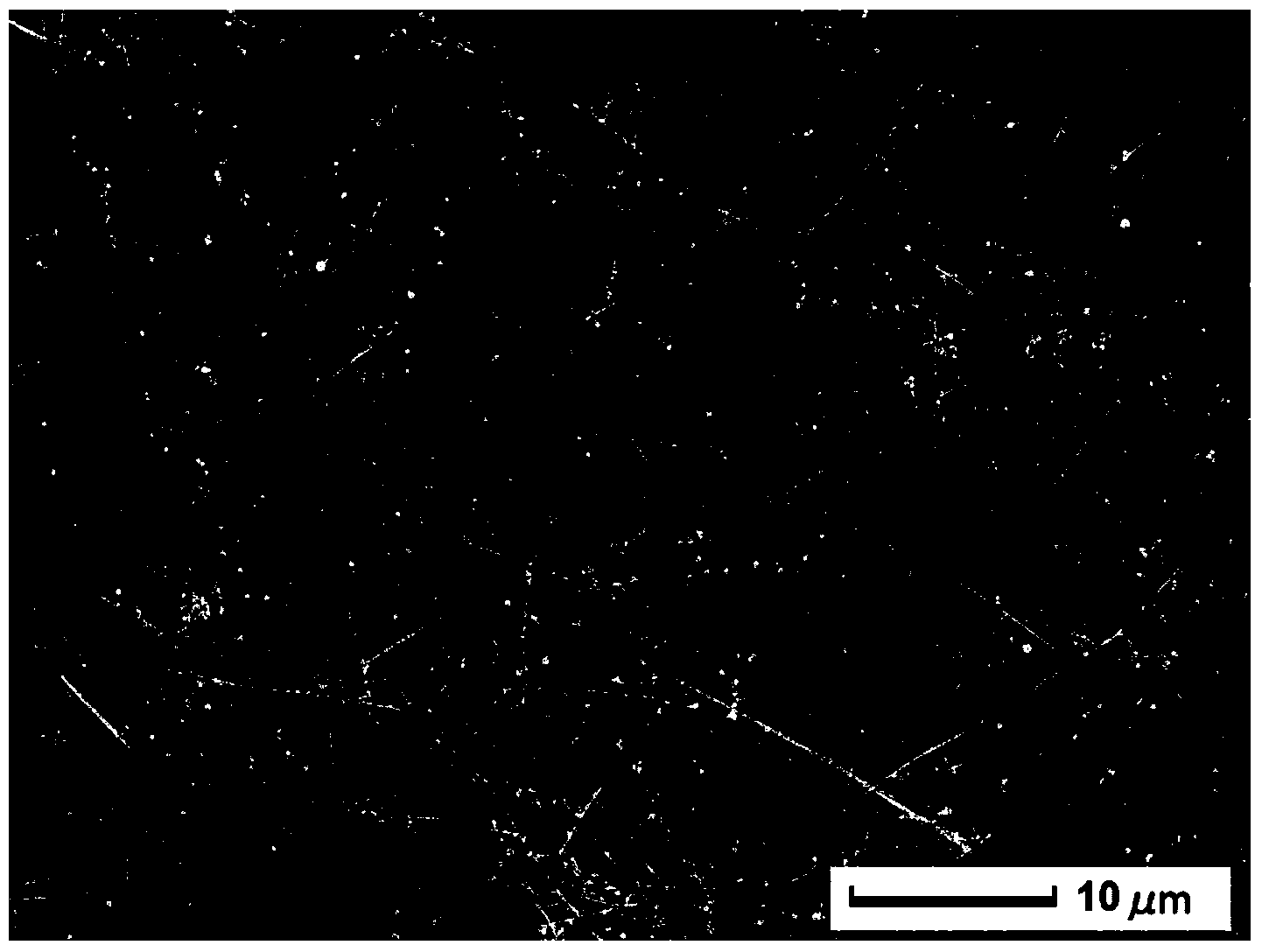

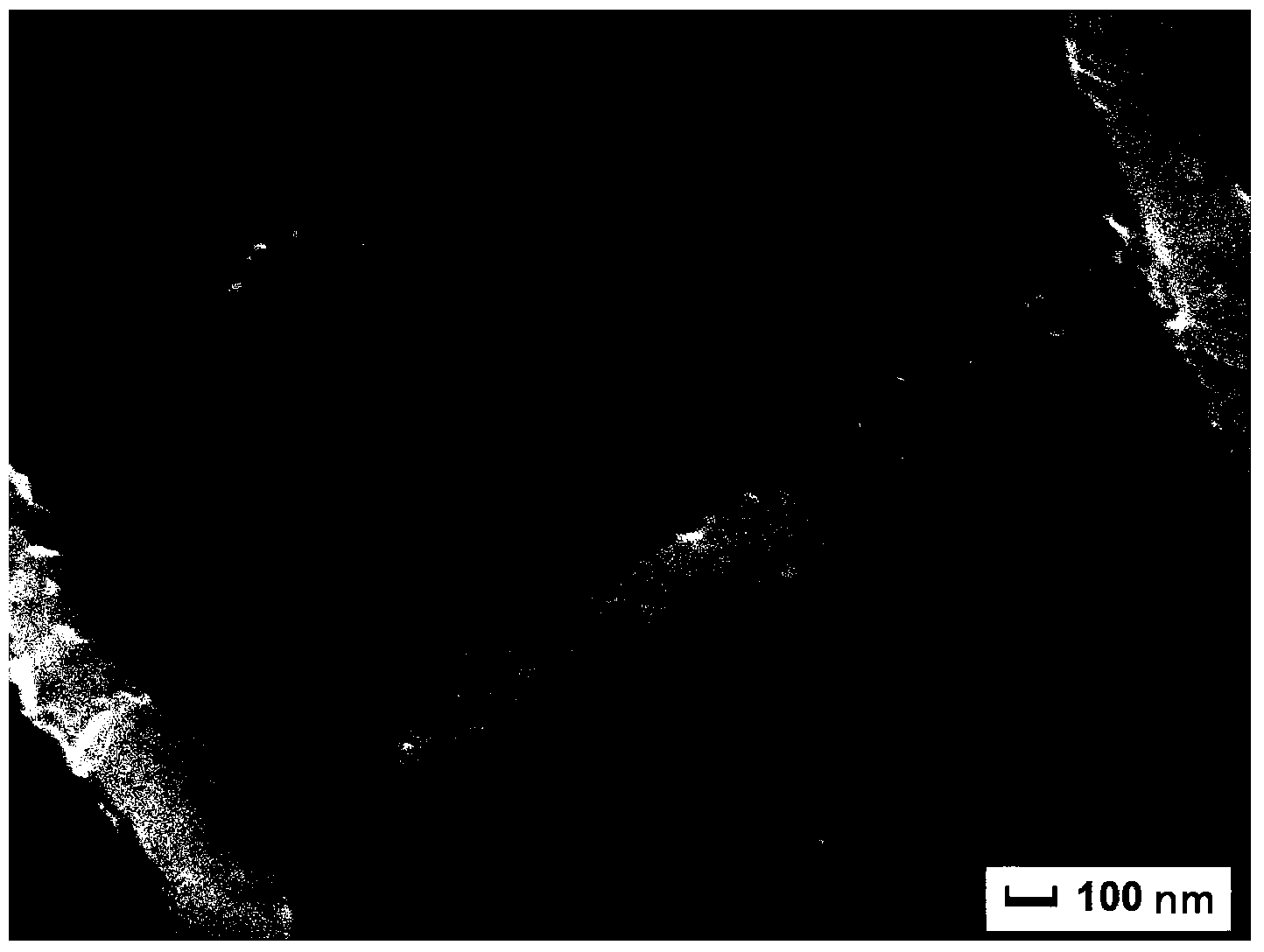

[0038] figure 1 , figure 2 The SEM photographs of the AgNWs / CNTs-PET composite flexible transpare...

Embodiment 2

[0047] (1) Take 0.16g of silver nanowires and 0.04g of carbon nanotubes and mix them in 100mL of absolute ethanol. After ultrasonic dispersion for 30 minutes, a mixed suspension is obtained, in which the silver nanowires are 70-90nm in diameter and 15-30μm in length. The tubes are 20-40nm in diameter and 5-15μm in length, all purchased from the market without other treatment;

[0048] (2) Take 10mL of the suspension to form a uniform film layer on a PET transparent substrate with a thickness of 350 μm and an area of 40cm×40cm by transfer printing. The surface density of silver nanowires and carbon nanotubes on the flexible transparent substrate is 0.0125mg / cm 2 ;

[0049] (3) Statically press the film layer together with the PET transparent substrate on a tablet press for 10 seconds under a pressure of 10 MPa to obtain an AgNWs / CNTs-PET composite flexible transparent conductive film.

[0050] Figure 7 It is a scanning electron microscope photo of AgNWs / CNTs-PET composit...

Embodiment 3

[0052] (1) Take 0.04g of silver nanowires and 0.01g of carbon nanotubes and mix them in 100mL of anhydrous acetone. After ultrasonic dispersion for 10 minutes, a mixed suspension is obtained, in which the silver nanowires are 30-50nm in diameter and 5-15μm in length. The tubes are 20-40nm in diameter and 5-10μm in length, all purchased from the market without other treatment;

[0053] (2) Dip a PBT transparent substrate with a thickness of 100 μm and an area of 40 cm × 40 cm in the suspension for 3 times to form a uniform film layer. The surface density of silver nanowires and carbon nanotubes on the flexible transparent substrate is 0.01 mg / cm 2 ;

[0054] (3) Statically press the film layer together with the PBT transparent substrate on a tablet press under a pressure of 2 MPa for 10 seconds to obtain an AgNWs / CNTs-PBT composite flexible transparent conductive film.

[0055] The results show that: AgNWs form the main conductive network, CNTs form the branch conductive n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com