Method for producing dissoluble carbon source needed by waste water denitrification from kitchen waste

A technology for kitchen waste and production wastewater, which is applied in the field of waste resource utilization and advanced wastewater treatment, can solve the problems of high nitrogen and phosphorus content in sludge, restrict further utilization, etc., achieve high dissolved carbon source concentration, reduce a large amount of pollution the effect of entering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, the method for producing waste water denitrification soluble carbon source using kitchen waste includes the unit processes of vortex gravity separation, pretreatment and anaerobic fermentation:

[0024] 1. Vortex gravity separation

[0025] Take 10 kg of solid food waste from a university cafeteria in Hefei, mix the solid food waste with water at a mass ratio of 1:5, and pass through a sieve with an aperture of 7 mm to remove plastic products, paper towels, bones, and large pieces of meat , disposable chopsticks and other sundries to obtain a mixture of kitchen waste; add the mixture of kitchen waste to a rotary kitchen waste component separator for vortex gravity separation, control the speed at 70-100 rpm, remove the upper floating As well as small bones and other heavy objects that sink to the bottom, the mixed sediment is collected from under the side of the separator, and the main component of the mixed sediment is carbohydrates.

[0026] 2. Pr...

Embodiment 2

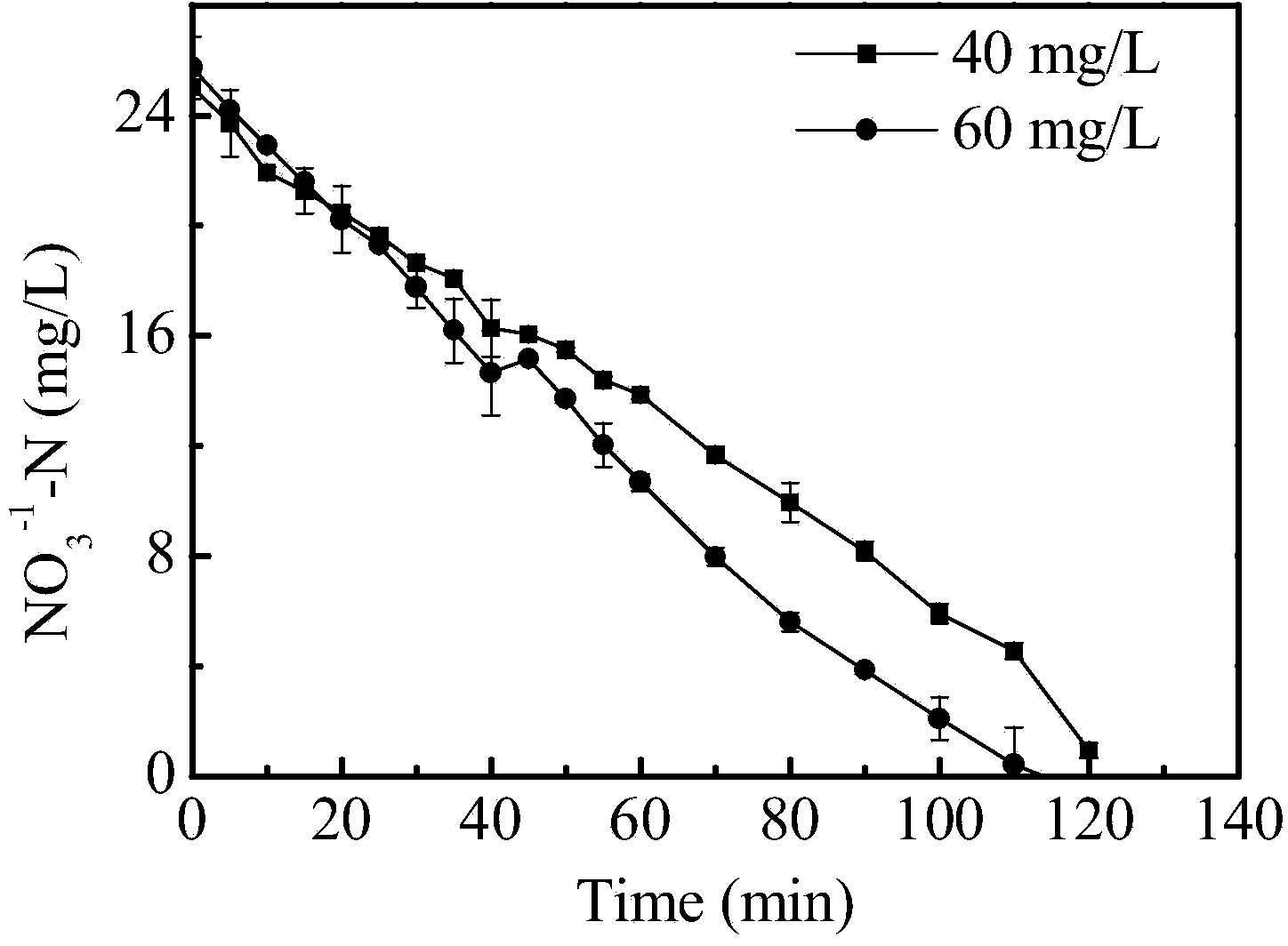

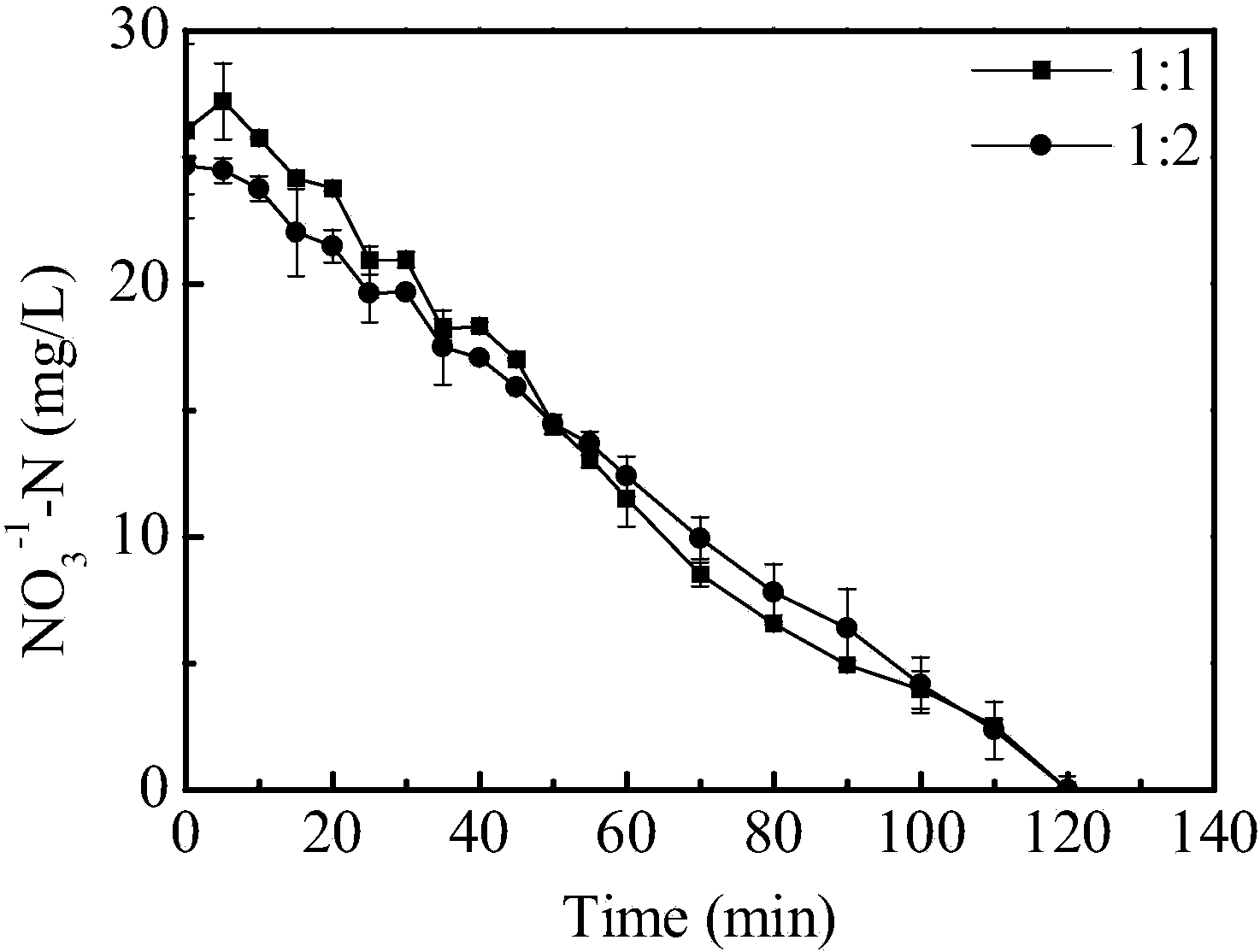

[0032] Embodiment 2: Utilize the dissolved carbon source of the present invention to treat waste water containing nitrate nitrogen

[0033] Inoculate the SBR reactor of 4L, according to shown in table 1, add potassium nitrate as nitrate (25mg / L nitrate radical), and add the mixed carbon source (10g / L) of acetic acid and n-butyric acid and the present invention's soluble carbon source respectively (10g / L), the denitrification reaction is carried out under the condition of micro-aerobic or anoxic (dissolved oxygen is less than 0.1mg / L). During the denitrification process, samples were taken at 0min, 5min, 10min, 15min, 20min, 25min, 30min, 35min, 40min, 45min, 50min, 55min, 60min, 70min, 80min, 90min, 100min, 110min, 120min, etc. 8 mL each time, immediately centrifuged with a desktop high-speed centrifuge at a speed of 10,000 rpm, centrifuged for 10 min, and filtered the supernatant after centrifugation, and analyzed the concentration changes of nitrate nitrogen and ammonia nitr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap