Device and method capable of controlling redox reduction potential to promote sludge dry method anaerobic fermentation

A dry anaerobic and sludge technology, which is applied in the field of solid waste recycling, achieves the effects of low energy consumption for heating and heat preservation, high production capacity per unit volume, growth enrichment and methane yield promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

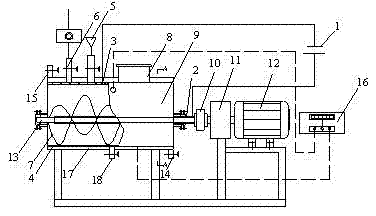

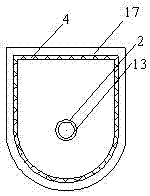

[0022] Such as figure 1 with figure 2 As shown, the device is composed of a fermentation tank body 9, an agitator, a motor 12, an anode 2, a cathode 3, a low-voltage DC power supply 1, a wire and a conductive material, wherein: the agitator adopts a double-layer ribbon agitator 7, which is electrically conductive Material 4 is made of carbon fiber conductive material. The fermentation tank body 9 is a cylindrical structure with a rotating shaft 13 at its axis. The double-layer ribbon agitator 7 is horizontally positioned on the rotating shaft 13, and the two ends of the rotating shaft 13 protrude from the fermentation tank. Outside the body 9, one end of the rotating shaft 9 is socketed with the anode 2, and the anode extends into the fermentation tank body 9. The end of the rotating shaft 13 is connected to the transmission 11 through the coupling 10, and the transmission 11 is connected to the motor 12. The tank of the fermentation tank body 9 A cathode 3 is provided on th...

Embodiment 2

[0026] The device described in Example 1 was used to further increase the solid content of the material in the reactor. First, add 6.0kg of inoculated sludge and 3kg of dewatered sludge to the fermentation tank, and operate in the mode of feeding and discharging once a day. The SRT is set to 20 days. During the start-up stage of the reactor, feed 450g into the reactor every day. Dewater sludge (solid content is generally 20%), while adjusting the output quality according to the gas volume (generally 1L of gas produced consumes 1g of organic matter), and gradually increase the organic load, when the solid content of the digestate in the reactor reaches the set When the level is fixed, the feed is adjusted to a level of 20% solid content by adding dewatered sludge and tap water. Adjust the rotation speed of the double-layer ribbon agitator to 60r / min, alternately run at the rotation / stop mode of 10min / 10min, control the temperature of the material in the fermentation tank to 55°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com