A kind of preparation method of organosilicon cationic waterborne polyurethane

A technology of water-based polyurethane and silicone, applied in the chemical industry, can solve the problems of water resistance, solvent resistance, heat resistance and gloss, poor mechanical properties of water-based polyurethane, easy yellowing of water-based polyurethane, etc., and meet the requirements of reaction equipment. High, improved water resistance and stretch resistance, easy to separate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A preparation method of organosilicon cationic waterborne polyurethane, the steps are as follows:

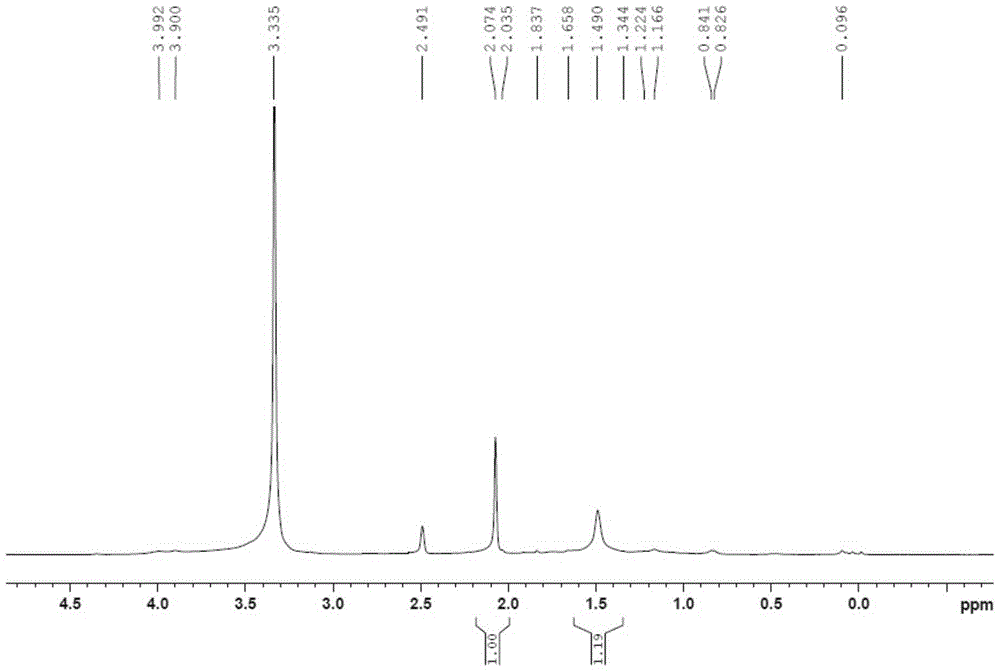

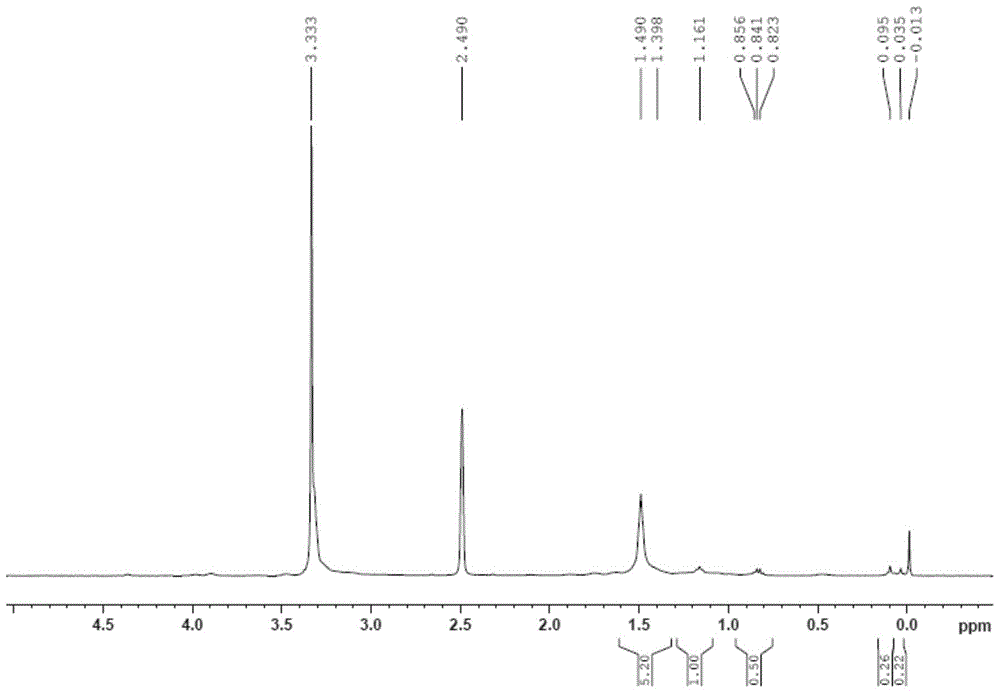

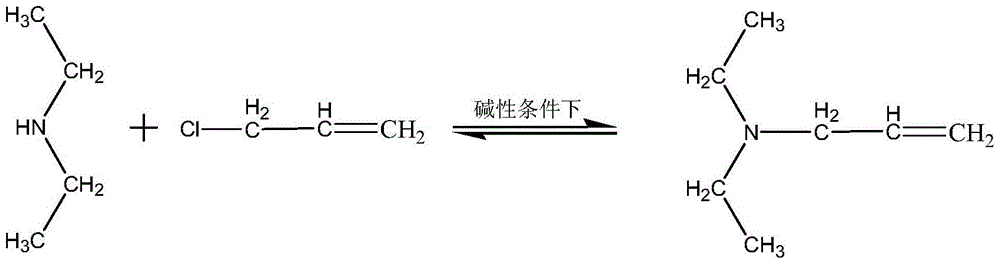

[0059] (1) Take 30ml of saturated sodium hydroxide solution and add it to a 500ml four-neck flask with reflux and a thermometer, heat up to 40°C, mix 15.466g (0.2021mol) of allyl chloride and 14.683g (0.2008mol) of diethylamine Drop by drop into a four-necked bottle, the time for dropping is 90min, heat up to 65°C, keep stirring at normal pressure for 16h, cool to room temperature, filter to obtain the filtrate, let it stand, separate the supernatant with a separatory funnel, Distilled under normal pressure to obtain a fraction with a boiling point of 104-106°C to obtain diethylallylamine; the product yield is 61%, and the purity is 99.2%;

[0060] The distilled fraction with a boiling point below 70°C can be reused;

[0061] (2) Take 5.170g of acidified cation exchange resin, 16.416g (0.1222mol) of tetramethyldisiloxane (HMM) and 35.594g (0.1200mol) of octamethylcyclote...

Embodiment 2

[0067] A preparation method of organosilicon cationic waterborne polyurethane, the steps are as follows:

[0068] (1) Take 30ml of saturated sodium hydroxide solution and add it to a 500ml four-neck flask with reflux and a thermometer, heat up to 40°C, mix 15.466g (0.2021mol) of allyl chloride and 14.683g (0.2008mol) of diethylamine Drop by drop into a four-necked bottle, the time for dropping is 90min, heat up to 65°C, keep stirring at normal pressure for 16h, cool to room temperature, filter to obtain the filtrate, let it stand, separate the supernatant with a separatory funnel, Distilled under normal pressure to obtain a fraction with a boiling point of 104-106°C to obtain diethylallylamine; the product yield is 61%, and the purity is 99.2%;

[0069] The distilled fraction with a boiling point below 70°C can be reused;

[0070] (2) Take 5.908g of acidified cation exchange resin, 13.579g (0.1000mol) of tetramethyldisiloxane (HMM) and 44.493g (0.15mol) of octamethylcyclotetr...

Embodiment 3

[0076] A kind of preparation method of organosilicon cationic waterborne polyurethane, step is the same as embodiment 1, difference is:

[0077] The temperature of the heat preservation reaction in the step (1) is 60 DEG C, and the heat preservation reaction time is 18h;

[0078] In step (2), the reaction temperature is 90°C, and the reaction time is 10h;

[0079] In step (3), the reaction temperature is 30°C, and the reaction time is 4h;

[0080] In step (4), the reaction temperature is 60°C, and the reaction time is 48h;

[0081] In step (5), the reaction temperature between polytetrahydrofuran diol and 4,4'-dicyclohexylmethane diisocyanate is 40°C, and the reaction time is 4h; The temperature is 40°C and the reaction time is 3h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com