A kind of preparation method of polyamide 6 thermoplastic elastomer resin

A thermoplastic elastomer and polyamide technology, which is applied in the field of a preparation method of a polyamide 6 thermoplastic elastomer resin, can solve the problems of undiscovered synthesis process route, high purity requirements of reaction raw materials, complicated solvent removal process, etc., and achieves toughness. High, good noise reduction, good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

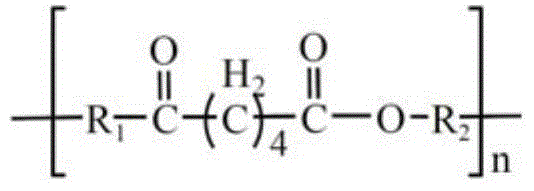

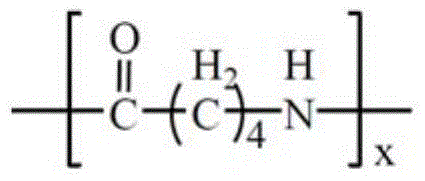

Method used

Image

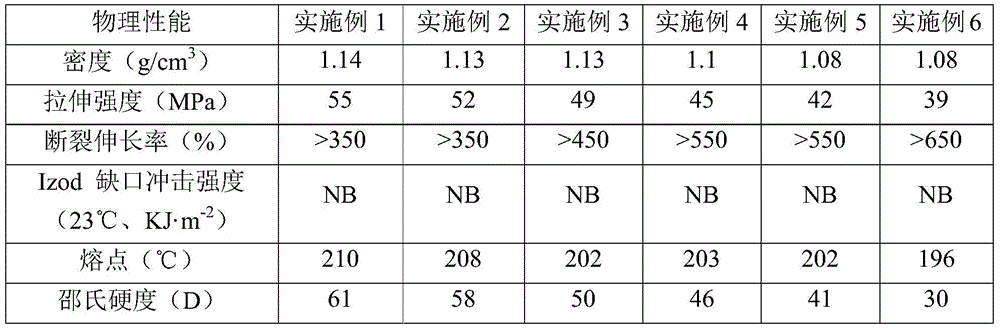

Examples

Embodiment 1

[0038] Add 10g of polyethylene glycol with a number average molecular weight of 1000, 90g of caprolactam, 3g of deionized water, 2g of phosphoric acid, and 10g of adipic acid into the reactor, heat up to 200°C under nitrogen protection, and react for 1 hour under mechanical stirring at 100rpm ; Then at 260°C, vacuumize to 20Pa and continue mechanical stirring at 100rpm for 3 hours, then extract with boiling water and dry.

Embodiment 2

[0040] Add 20g of polyethylene glycol with a number average molecular weight of 2000, 80g of caprolactam, 3g of deionized water, 3g of sulfuric acid, and 1g of adipic acid into the reactor, heat up to 240°C under nitrogen protection, and react for 1.5 hours under mechanical stirring at 800rpm ; Then at 260°C, vacuumize to 40Pa and continue mechanical stirring at 800rpm for 2.5 hours, then extract with boiling water and dry.

Embodiment 3

[0042] Add 30g of polytetrahydrofuran with a number average molecular weight of 4000, 70g of caprolactam, 2g of deionized water, 3g of aminocaproic acid, and 5g of adipic acid into the reactor. Under the protection of nitrogen, heat up to 220°C and react for 0.5 hours under mechanical stirring at 300rpm ; Then at 250°C, vacuumize to 80Pa and continue mechanical stirring at 300rpm for 2 hours, then extract with boiling water and dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com