Ph responsive polyion liquid composite membrane and preparation method thereof

A technology of polyionic liquids and composite membranes, applied in the field of polymer materials, can solve the problems of poor reusability, narrow pH response range, and inability to recycle, and achieve good reusability, short response time, and low electronic The effect of cloud density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

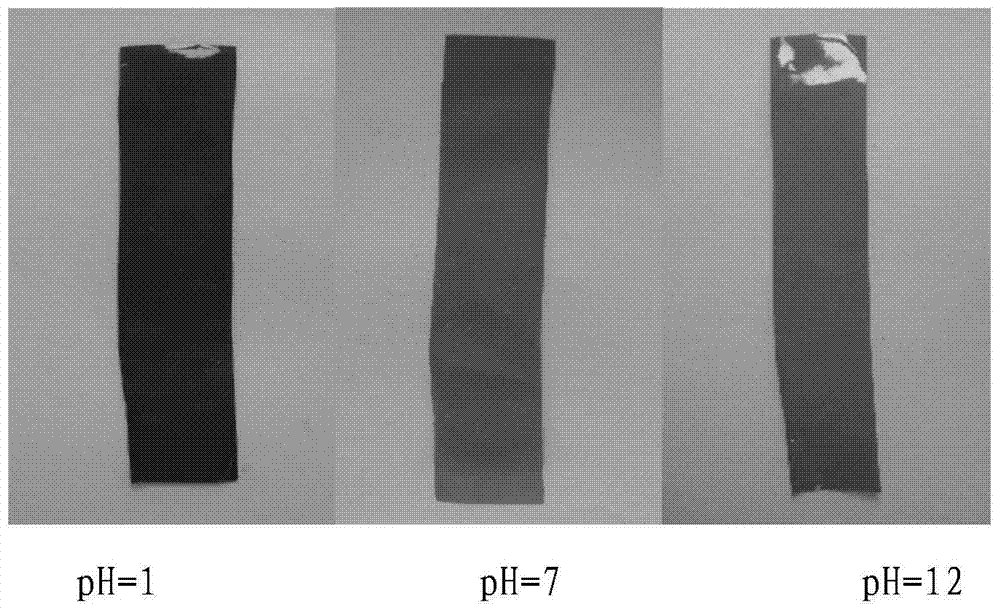

[0026] This embodiment provides a method for preparing a pH-responsive polyionic liquid composite membrane, which includes the following steps in sequence:

[0027] (1) take 0.6g, 0.2g of acrylonitrile, 0.008g of benzoin ethyl ether, and 0.064g of divinylbenzene. Mix the above substances evenly with ultrasonic waves, apply them on a glass plate mold, and light for 40min to obtain a polyionic liquid composite film;

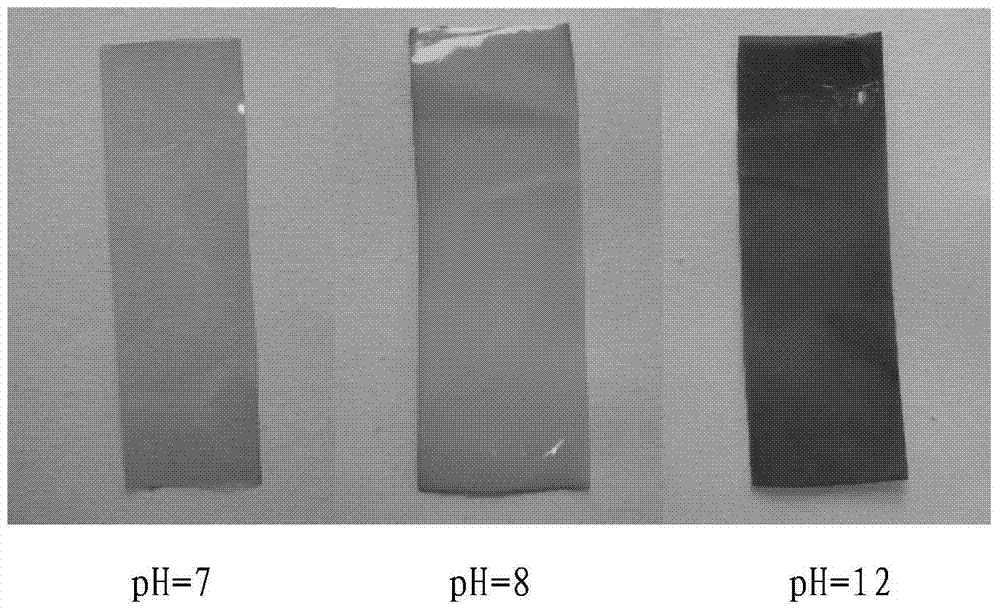

[0028] (2) Take a polyionic liquid composite membrane with a mass of 0.1 g and immerse it in 0.1062 g of a methyl orange aqueous solution with a concentration of 2 mg / mL for 40 min for anion exchange. - Converted to , washed repeatedly with ethanol to finally get the anion as pH-responsive polyionic liquid composite membrane.

Embodiment 2

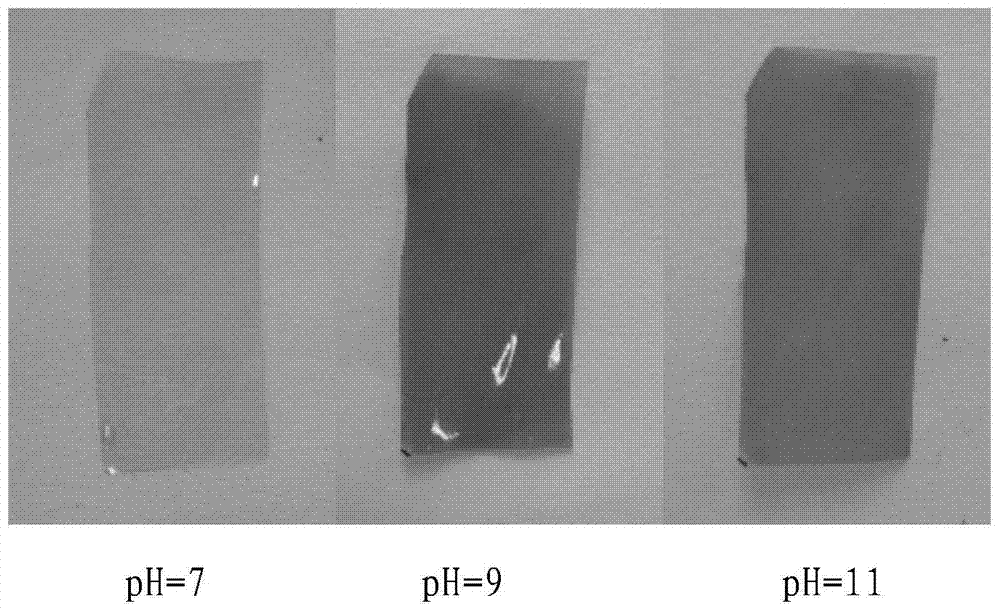

[0030] This example provides a method for preparing a pH-responsive polyionic liquid composite membrane, which is roughly the same as that in Example 1, except that the polymeric imidazole monomer used is .

Embodiment 3

[0032] This example provides a method for preparing a pH-responsive polyionic liquid composite membrane, which is roughly the same as that in Example 1, except that the polymeric imidazole monomer used is .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com