Aluminum alloy surface modification method

A technology of aluminum alloy surface and aluminum alloy plate, applied in the field of material surface treatment and strengthening, can solve the problems of cracking, combined interface cracks, etc., to achieve good wear resistance, improve surface strength, improve wear resistance and corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

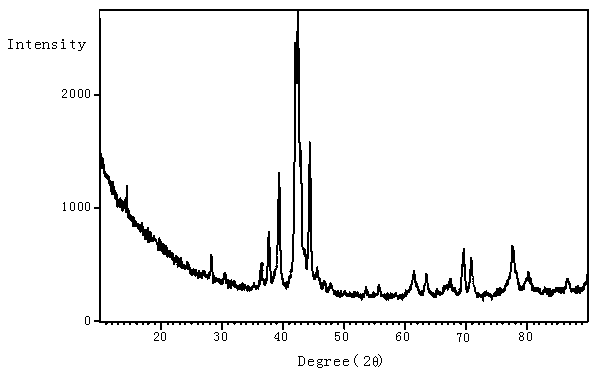

[0037] Example 1, see figure 1 , figure 2 , Weigh Cr, Ti, Si, V and Al powders with electronic balance FA2004N, the molar ratio of each powder is: 23% Cr, 28% Ti, 21% Si, 27% V, 1% Al, And put the weighed powder in the ball mill and mix well, the mixing time is 4 hours. Then configure 4% polyvinyl alcohol as an adhesive, and heat it in a water bath for about 10 minutes to completely dissolve it. Polish the aluminum alloy plate with metallographic sandpaper to remove the oxide film on the surface, and clean it with acetone. Blend the mixed powder into a viscous shape with the prepared adhesive, and pre-coat it on the cleaned aluminum alloy plate with a coating thickness of 0.5mm, and dry it for about 3 hours. The UW-600A YAG laser is used to irradiate the prefabricated coating on the aluminum alloy, and the high-purity argon gas is used for protection. The defocus of the laser focal spot is 3mm, the pulse width is 6ms, the laser peak power is 8kw, the frequency is 8HZ, and...

Embodiment 2

[0039] Embodiment 2, weigh Cr, Ti, Si, V and Al powder with electronic balance FA2004N, molar ratio is: 21% Cr, 25% Ti, 23% Si, 28% V, 3% Al, And put the weighed powder into the ball mill and mix well, the mixing time is 5 hours. Then configure 4% polyvinyl alcohol as an adhesive, and heat it in a water bath for about 10 minutes to completely dissolve it. Polish the aluminum alloy plate with metallographic sandpaper to remove the oxide film on the surface, and clean it with acetone. Blend the mixed powder into a viscous shape with the prepared adhesive, and pre-coat it on the cleaned aluminum alloy plate with a coating thickness of 0.5mm, and dry it for about 3 hours. The UW-600A YAG laser is used to irradiate the prefabricated coating on the aluminum alloy, and the high-purity argon gas is used for protection. The defocus of the laser focal spot is 3mm, the pulse width is 6ms, the laser peak power is 8kw, the frequency is 8HZ, and the scanning speed is 5mm / s. Combined with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com