Slab laser amplifier and laser output method

A technology of laser amplifiers and slabs, which is applied to lasers, laser components, phonon exciters, etc., can solve the problems of low pump gain utilization and large folding angles, and achieve the goals of reducing thermal effects, small width, and improving utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

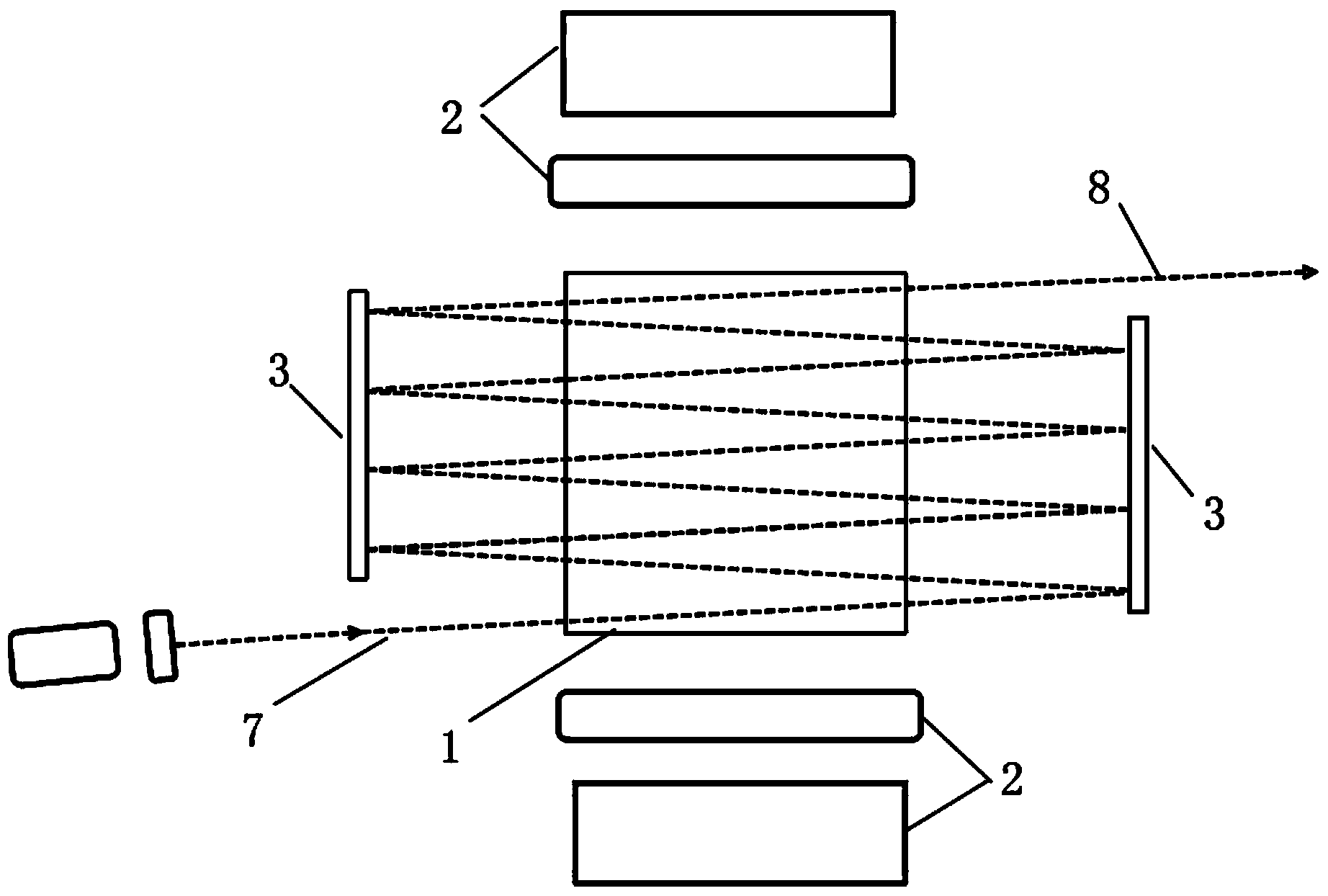

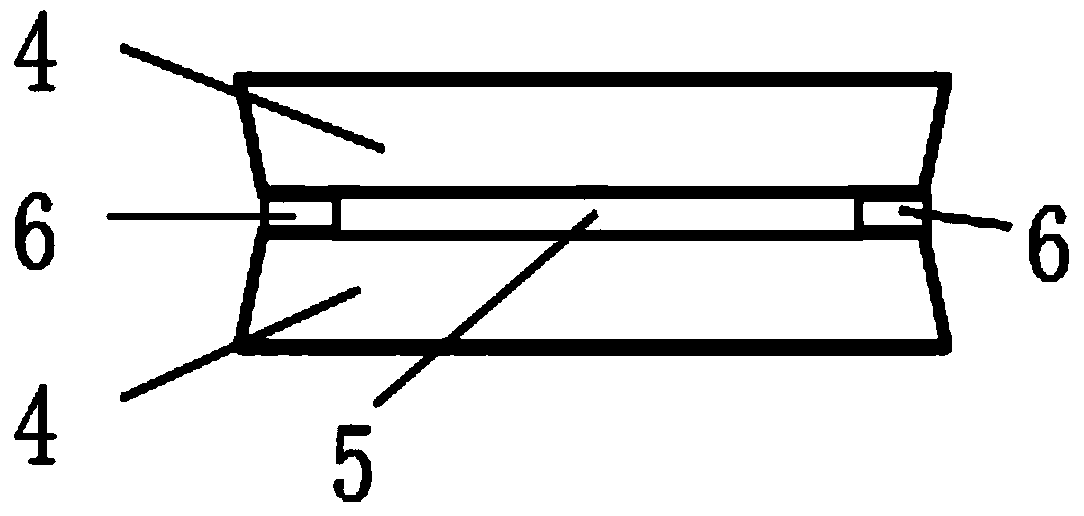

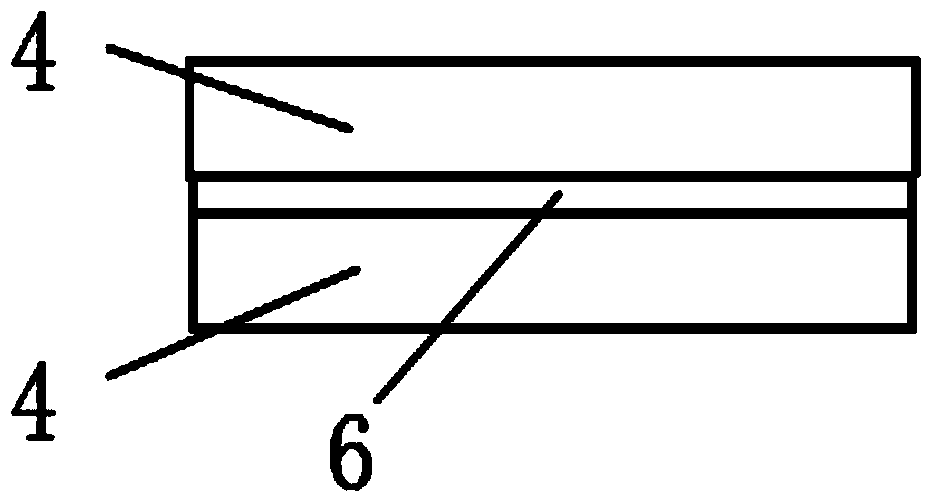

[0036] Such as Figure 1 to Figure 3 As shown, a slab laser amplifier includes a gain medium module 1 and a pump module 2. The gain medium module 1 includes a laser crystal and two cooling heat sinks 4, and the two cooling heat sinks 4 are respectively fixed on the width of the laser crystal. On both sides of the side; the pump module 2 is provided with two; also includes a mirror module, the mirror module includes two mirrors 3, located on the left and right sides of the gain medium module 1, the two pumps Module 2 is located on both sides of the front and back of gain medium module 1, and the pump laser light can directly enter gain medium module 1 without passing through a plane mirror, and then enter gain medium module 1, which reduces the energy loss of pump laser light; The thickness of the laser crystal is 0.5-1.5 mm. Compared with the prior art, the thickness of the laser crystal is smaller, which is beneficial to the heat dissipation of the laser crystal and enhances ...

Embodiment 2

[0038] Such as Figure 1 to Figure 3According to a slab laser amplifier described in Embodiment 1, the length and width of the laser crystal are greater than the thickness, the length of the laser crystal is 5-1000 mm, and the width is 5-500 mm. The non-doped laser crystal 6 has a width of 0.5 to 1.5mm; the non-doped laser crystal 6 is a yttrium aluminum garnet crystal, and the doped laser crystal 5 is a neodymium-doped yttrium aluminum garnet crystal or a ytterbium-doped yttrium aluminum garnet crystal or the aforementioned The non-doped laser crystal 6 is yttrium acid crystal, the doped laser crystal 5 is neodymium-doped yttrium vanadate crystal, and the doped laser crystal 5 and the non-doped laser crystal 6 are homogeneous substrates, so that the doped laser crystal 5 and the non-doped laser crystal Glue-free bonding can be realized between the laser crystals 6; a layer of indium is placed between the laser crystal and the cooling heat sink 4, and indium has a strong heat ...

Embodiment 3

[0040] Such as Figure 1 to Figure 3 According to a slab laser amplifier described in Embodiment 2, the two reflectors 3 are flat mirrors, and the inner surfaces of the two reflectors 3 are coated with a film with high reflectivity for the input seed laser 7-band , ensuring the multiple reflections of the input seed laser 7, preventing the input seed laser from being transmitted through the reflector 3, thereby causing energy loss; the two reflectors 3 are parallel to the side of the gain medium module 1, preventing the input seed laser 7 from being reflected during the reflection process A larger incident angle is formed in the middle, thereby reducing the number of incidents; the two reflectors 3 are centered on the central axis perpendicular to the two reflectors 3, and there is a certain deflection angle, and the deflection clamp between the two reflectors 3 The angle is 1′~100′, avoiding the formation of a flat cavity resonant structure and preventing laser self-excited o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com