Polyimide resin composition, film, adhesive agent and component

A technology of polyimide resin and composition, used in adhesives, electrical components, coatings, etc., can solve problems such as peeling, inability to apply high temperature processes, and resin stress, and achieve excellent mechanical properties and heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

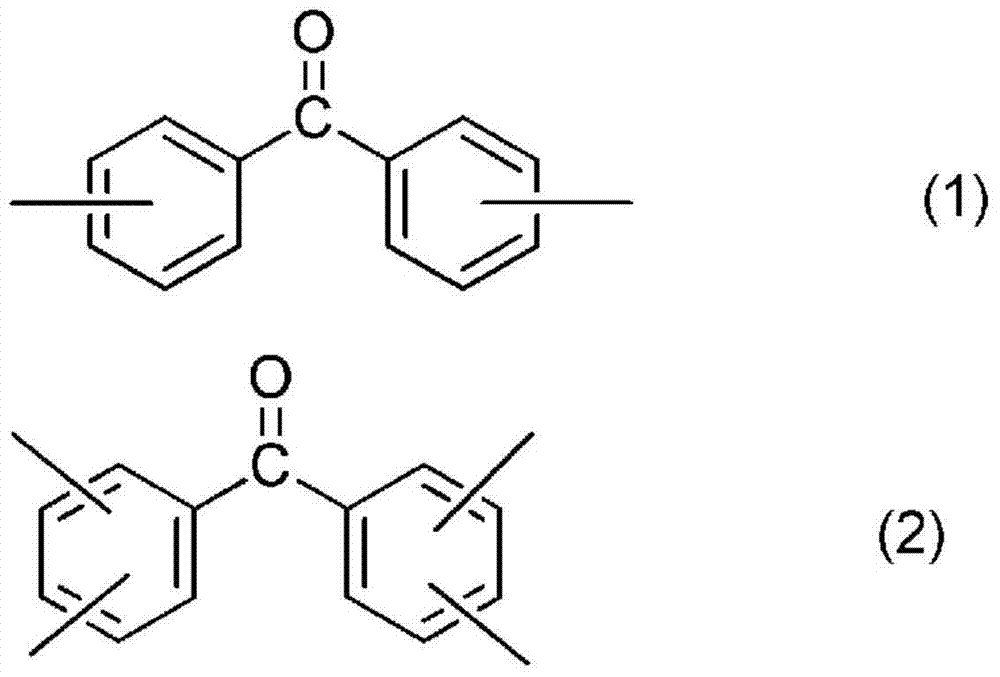

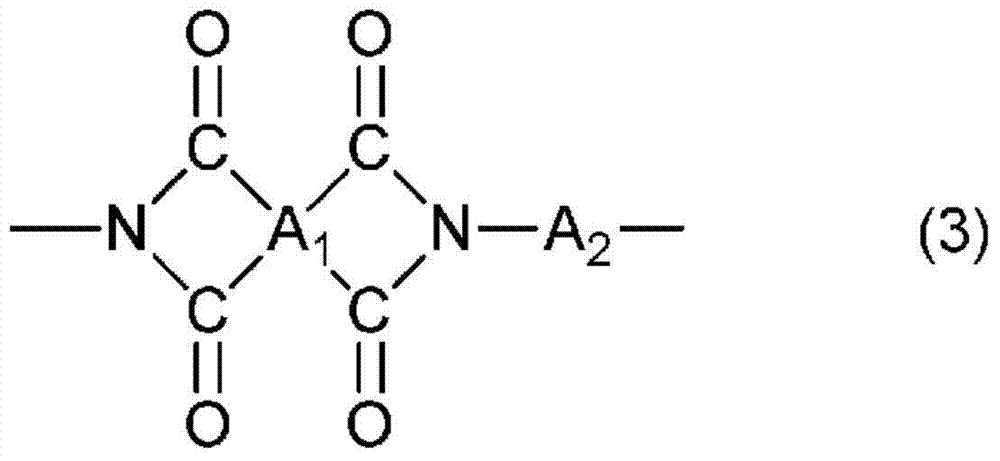

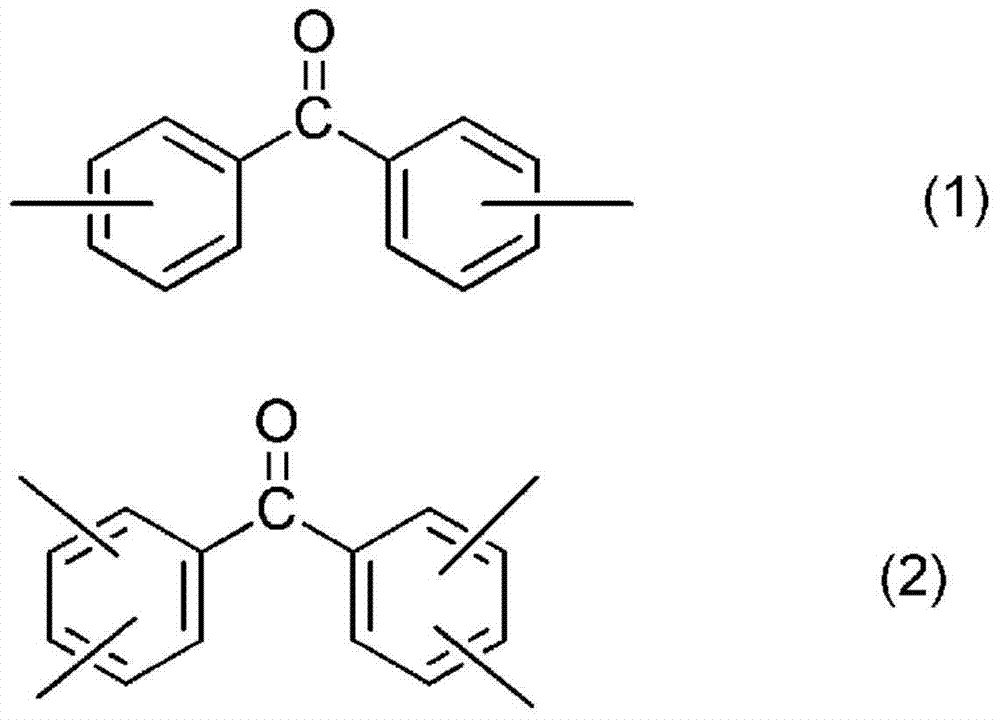

[0114] (Preparation of polyimide resin composition) 1,3-bis( 3-aminophenoxy)benzene (hereinafter referred to as "APB-N"), and 3,3',4,4'-biphenyltetracarboxylic dianhydride (hereinafter referred to as "s-BPDA") (JFE Chemical Co., Ltd.), 3,3',4,4'-benzophenone tetracarboxylic dianhydride (hereinafter referred to as "BTDA"), APB-N:s-BPDA:BTDA=1.0 :0.69:0.3 molar ratio was compounded. The obtained mixture was stirred for 4 hours or more in a flask into which dry nitrogen gas could be introduced, and a polyamic acid solution having a resin solid content mass of 18 to 25% by mass was obtained. After fully stirring, stir in the flask attached to the Dean-Stark tube, and at the same time heat the reaction system to about 180°C, and take out the water generated by the dehydration reaction to the outside of the system, thus obtaining polyimide resin composition.

[0115] (Preparation of polyimide film) The said polyimide resin composition was apply|coated on the PET film which perfor...

Embodiment 2

[0130] In a solvent adjusted by NMP and mesitylene at a ratio of 8:2, 2,2-bis[4-(4-aminophenoxy)phenyl]propane (hereinafter referred to as "p-BAPP ”) and two kinds of acid dianhydrides, s-BPDA and BTDA, were compounded at a molar ratio of pBAPP:s-BPDA:BTDA=1.0:0.79:0.2. Except for this compounding ratio, other conditions were carried out similarly to Example 1, and the polyimide resin composition was prepared. Furthermore, a polyimide film was produced by the method similar to Example 1, and it evaluated.

Embodiment 3

[0132] APB-N, 4,4'-bis(3-aminophenoxy)biphenyl (hereinafter referred to as "mBP") was mixed in a solvent prepared by adjusting the ratio of NMP and mesitylene to 8:2. These two diamines, s-BPDA, BTDA, and 4,4'-oxydiphthalic anhydride (hereinafter referred to as "ODPA"), three acid dianhydrides are represented by APB-N:mBP:s- The molar ratio of BPDA:BTDA:ODPA=0.5:0.5:0.2:0.3:0.49 was compounded. Except for this compounding ratio, other conditions were carried out similarly to Example 1, and the polyimide resin composition was prepared. Furthermore, a polyimide film was produced by the method similar to Example 1, and it evaluated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com