Synthesis technique of 9-fluorenone

A synthesis process, the technology of fluorenone, which is applied in the field of synthesis of aromatic compounds, can solve the problems of low boiling point of tetrahydrofuran, high reaction temperature, large investment of fluorenone, etc., and achieve saving of operation cost and maintenance cost, mild reaction conditions, and simplified preparation The effect of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

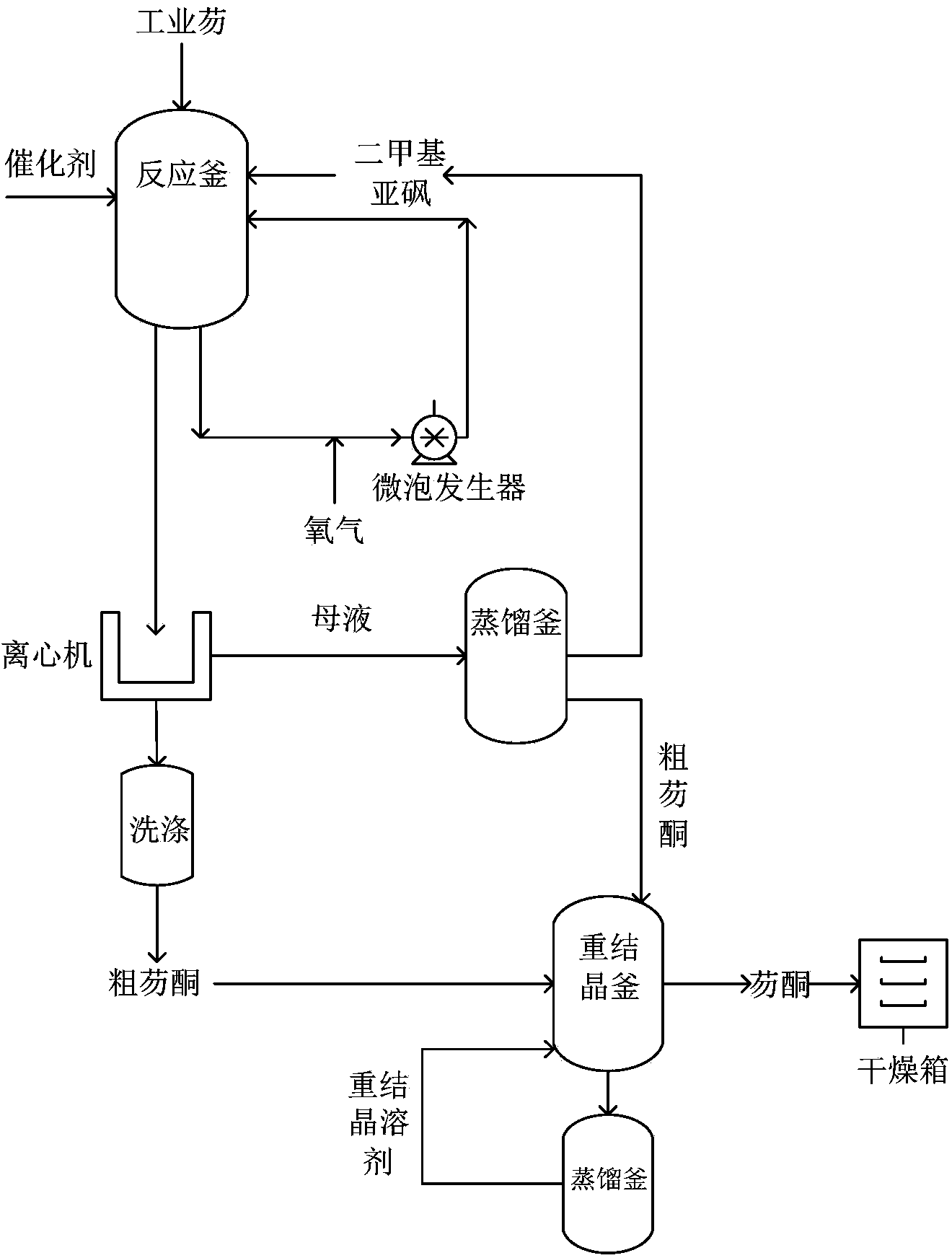

[0028] The synthesis process of 9-fluorenone uses industrial fluorene as raw material, sodium hydroxide as catalyst, and dimethyl sulfoxide as solvent. The material is heated and dissolved in the reactor, circulated outside the reactor, and returned through the microbubble generator. React in the reactor, and the reacted material is cooled and crystallized, separated, washed, and recrystallized to obtain fluorenone; the specific steps are as follows:

[0029] 1) Put 2kg of industrial fluorene, 2.2kg of dimethyl sulfoxide and 0.025kg of sodium hydroxide into a 100L reactor, set the temperature at 40°C, stir under normal pressure, and heat to dissolve;

[0030] 2) The circulation pipeline connected to the reaction kettle starts to be fed with oxygen for oxidation, and the material flowing out of the bottom of the reaction kettle is returned to the reaction kettle through the microbubble generator on the circulation pipeline together with oxygen, and the oxygen flow rate is 0.08m ...

Embodiment 2

[0036] The synthesis process of 9-fluorenone uses industrial fluorene as raw material, sodium hydroxide as catalyst, and dimethyl sulfoxide as solvent. The material is heated and dissolved in the reactor, circulated outside the reactor, and returned through the microbubble generator. React in the reactor, and the reacted material is cooled and crystallized, separated, washed, and recrystallized to obtain fluorenone; the specific steps are as follows:

[0037] 1) Put 2kg of industrial fluorene, 8kg of dimethyl sulfoxide and 0.2kg of sodium hydroxide into a 100L reactor, set the temperature at 80°C, stir under normal pressure, and heat to dissolve;

[0038] 2) The circulation pipeline connected to the reaction kettle starts to be fed with oxygen for oxidation, and the material flowing out of the bottom of the reaction kettle is returned to the reaction kettle through the microbubble generator on the circulation pipeline together with oxygen, and the oxygen flow rate is 1m 3 / h, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com